Pumps are critical components in industries like 石油とガス, power generation, chemical processing, and marine operations.

A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable.

Tungsten carbide seal rings are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers.

Why Leak-Free Pump Operation Matters

Prevents fluid loss → Protects resources and reduces waste.

Maintains efficiency → Pumps perform better without pressure loss.

Reduces maintenance costs → Fewer failures mean fewer repairs.

Protects the environment → Prevents spills of hazardous materials.

Ensures safety → Avoids dangerous leaks near operators or equipment.

炭化タングステンシールリングの特性

炭化タングステンは、タングステンと炭素がコバルトまたはニッケルと結合した化合物です。その特性は以下のとおりです。

過激 硬度 → 摩擦や粒子による摩耗に耐えます。

高い圧縮強度 → Handles heavy loads without cracking.

耐腐食性 → Works well with chemicals, seawater, and oils.

熱安定性 → Maintains sealing performance under high heat.

寸法安定性 → Ensures precise sealing over long periods.

These properties help pumps stay leak-free under tough conditions.

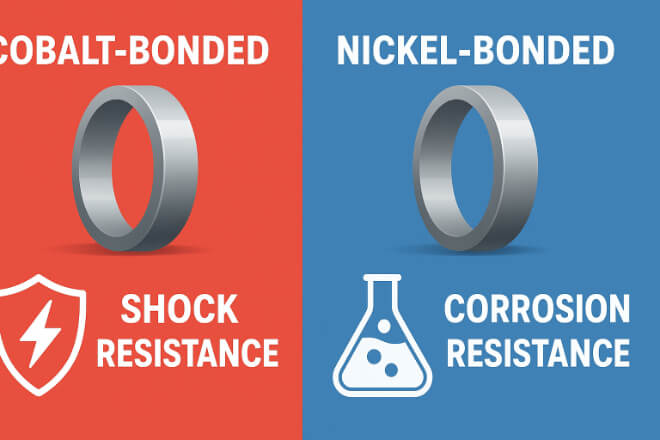

コバルト結合タングステンカーバイドとニッケル結合タングステンカーバイド

1)コバルト結合炭化タングステン

Best for vibration-heavy or high-shock pumps.

Common in oilfield and mining operations.

2)ニッケル結合タングステンカーバイド

優れた 耐腐食性。

Ideal for chemical plants, marine pumps, and wastewater systems.

Choosing the right binder ensures long service life and reliable sealing.

他のシール材に対する利点

| 特徴 | タングステンカーバイド | セラミック | 鋼鉄 |

|---|---|---|---|

| 耐摩耗性 | 研磨剤に最適 | 適度 | 貧しい |

| 耐腐食性 | High (nickel grades) | とても良い | 低い |

| 強靭さ | 高くて衝撃に強い | 低く、脆い | 適度 |

| Thermal Performance | Excellent at high heat | 良い | 適度 |

| Service Life | 長持ちする | 適度 | 短い |

Applications in Pump Systems

タングステンカーバイドシールリングは次のような用途に使用されます。

Chemical pumps → Handle aggressive fluids safely.

船舶用ポンプ → Resist seawater corrosion.

Oil and gas pumps → Prevent leaks under pressure.

Wastewater pumps → Manage abrasive and corrosive fluids.

発電所の冷却ポンプ → Maintain leak-free operation for critical systems.

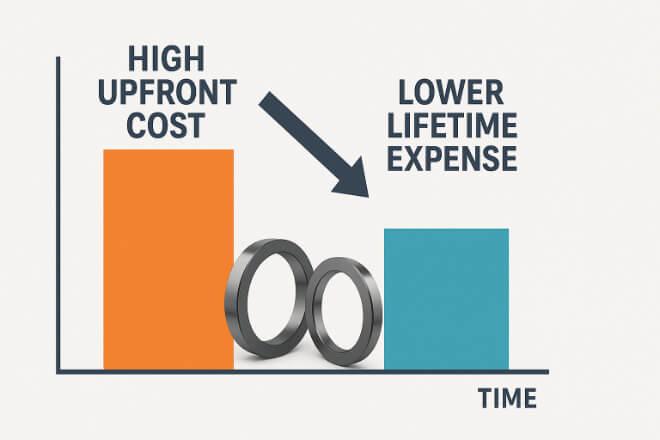

コスト vs 長期的な価値

While tungsten carbide rings cost more upfront:

交換品の減少 → スペアパーツのコストを削減します。

ダウンタイムの短縮 → Increases production efficiency.

Extended equipment life → Protects pump components.

より良いROI → Long-term savings outweigh initial price.

Environmental and Safety Benefits

Leak prevention → Avoids contamination and environmental damage.

Recyclable material → Supports sustainable practices.

Energy efficiency → Preventing leaks reduces wasted energy.

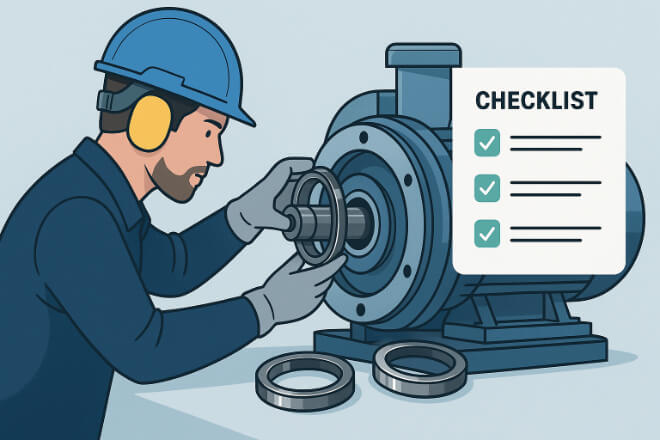

Best Practices for Leak-Free Performance

Select the right binder → Match to chemical and mechanical conditions.

Ensure proper installation → 傷やずれを避けてください。

適切な潤滑剤を使用する → Reduces friction and heat.

定期的に検査する → Catch wear early before leaks start.

Partner with reliable suppliers → 材料の品質と正しい仕様を確認します。

意思決定者にとっての重要なポイント

Tungsten carbide seal rings ensure leak-free pump operation under tough conditions.

Choosing the correct grade (nickel or cobalt) is critical for performance.

Their durability, recyclability, and efficiency lower costs and environmental risks.

Investing in tungsten carbide protects pumps and improves ROI.

結論

For pumps in chemical plants, power stations, marine systems, and oilfields, tungsten carbide seal rings are a proven choice for preventing leaks.

Their hardness, corrosion resistance, and strength deliver long-term performance, reduced downtime, and environmental protection.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, sustainability, and cost efficiency.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。