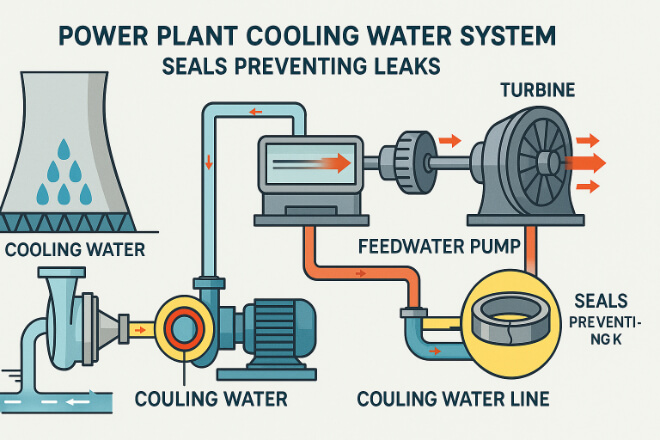

Power plants rely on cooling water systems to manage heat and keep turbines, pumps, and generators running safely.

Any leak or failure in these systems can lead to downtime, efficiency loss, or environmental damage.

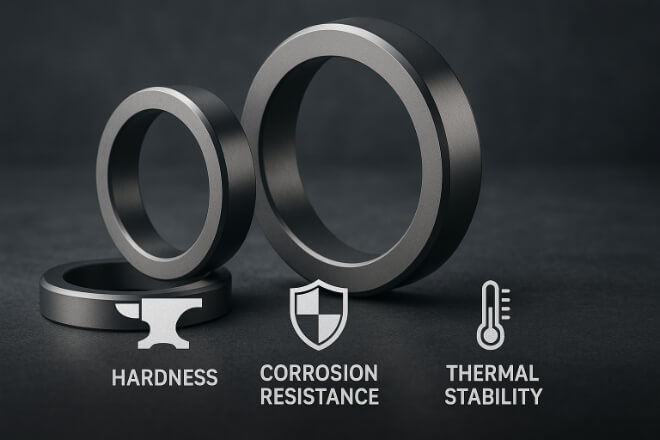

Tungsten carbide seal rings are one of the most reliable materials for pumps and compressors in cooling water systems.

This article explains why they are essential, their benefits, and how to use them effectively.

Why Cooling Water Systems Need Reliable Seals

Prevent leaks → Protect equipment and reduce water loss.

Maintain efficiency → Proper seals help pumps operate at full performance.

ダウンタイムを削減 → Reliable seals minimize unplanned maintenance.

Avoid contamination → Prevents cooling water from mixing with other fluids.

Protect the environment → Stops harmful discharges into natural water sources.

炭化タングステンシールリングの主な特性

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. It offers:

他のシール材に対する利点

| 特徴 | タングステンカーバイド | セラミック | 鋼鉄 |

|---|---|---|---|

| 耐摩耗性 | 研磨剤に最適 | 適度 | 貧しい |

| 耐腐食性 | High (nickel grades) | Very Good | 低い |

| 強靭さ | 高くて衝撃に強い | 低く、脆い | 適度 |

| Thermal Performance | Excellent at high heat | 良い | 適度 |

| Service Life | 長持ちする | 適度 | 短い |

Applications in Power Plant Cooling Water Systems

タングステンカーバイドシールリングは、次のような用途で広く使用されています。

Main cooling water pumps → Ensure reliable, leak-free operation.

Circulating pumps → Maintain water movement for turbine efficiency.

Auxiliary systems → Protect small pumps in control circuits.

Brackish water systems → Resist corrosion in coastal plants.

Backup generators → Provide sealing under varying temperatures and pressures.

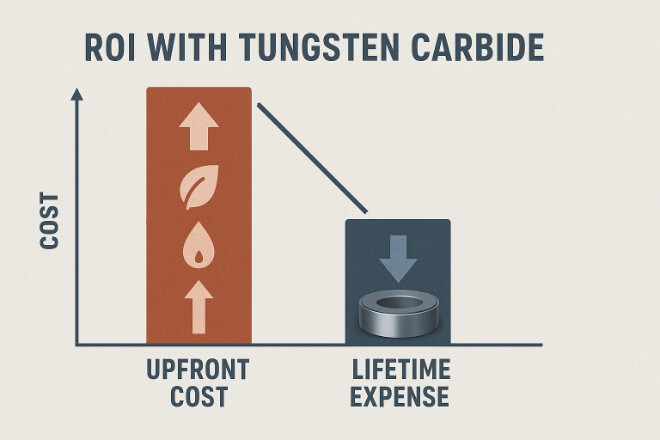

コスト vs 長期的な価値

Although tungsten carbide seal rings cost more upfront:

ダウンタイムを削減 → Fewer failures mean less lost production.

Lower maintenance → Longer service life reduces labor and spare parts.

機器を保護する → Prevents damage to expensive pumps and turbines.

ROIの向上 → Long-term savings offset initial costs.

Environmental and Safety Benefits

Leak prevention → Protects local water sources and ecosystems.

Recyclable material → Supports power plants’ sustainability goals.

Efficient performance → Reduces wasted energy in pumps and compressors.

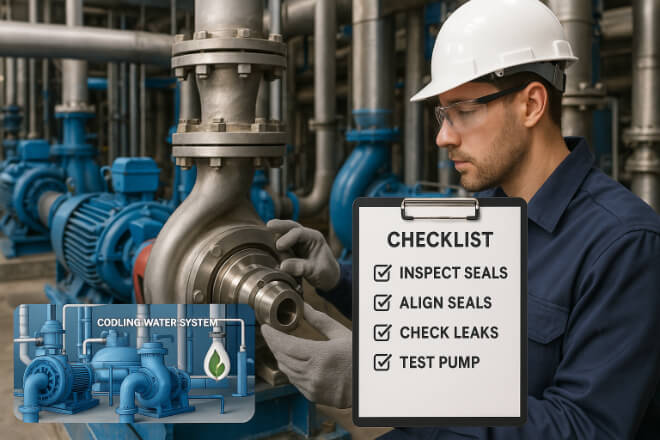

タングステンカーバイドシールリングの使用に関するベストプラクティス

適切なバインダーを選ぶ → Nickel for brackish or chemical-rich water, cobalt for vibration-heavy pumps.

Inspect seals regularly → 摩耗を早期に検出して故障を防止します。

Ensure proper installation → Avoid scratches or misalignment during assembly.

Maintain proper lubrication → Prevent dry running that can damage seals.

Work with trusted suppliers → Get quality materials and accurate specifications.

意思決定者にとっての重要なポイント

Tungsten carbide seal rings are the best choice for power plant cooling water systems.

They combine durability, 耐腐食性、 そして 強靭さ for long-term performance.

Higher upfront cost delivers better ROI through reduced downtime and maintenance.

Proper selection and care ensure reliable, leak-free operation.

結論

Power plant cooling water systems demand seals that can perform under pressure, temperature shifts, and corrosive conditions.

Tungsten carbide seal rings deliver the strength and reliability required to keep operations efficient and safe.

For decision-makers, investing in tungsten carbide ensures long-term savings, environmental protection, and operational reliability.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。