In food and pharmaceutical manufacturing, every part of a machine must perform with precision, cleanliness, and long-term reliability.

Equipment is constantly exposed to moisture, cleaning chemicals, and repetitive stress.

Bushings — small but essential components that support rotating shafts — are often the first to fail if not made from the right material.

When a bushing wears out, it can cause vibration, leakage, or contamination, leading to costly downtime.

That is why タングステンカーバイドブッシング have become a preferred choice for critical food and pharmaceutical machinery.

They offer unmatched durability, 耐腐食性, and smooth surface finish, ensuring reliability while maintaining hygienic standards.

Challenges in Food and Pharmaceutical Machinery

Unlike general industrial environments, equipment in food and pharmaceutical plants must meet strict sanitary and operational standards.

Components face not only wear and friction but also exposure to aggressive cleaning and sterilization processes.

Common challenges include:

Constant exposure to water, steam, and sanitizing chemicals.

Frequent high-temperature cleaning cycles (CIP/SIP).

Corrosive ingredients, such as acids, enzymes, and solvents.

Strict hygiene and contamination control standards.

Continuous operation and limited downtime for maintenance.

In such conditions, ordinary steel or polymer bushings may degrade quickly. Tungsten carbide bushings, however, maintain performance and integrity under these demanding conditions.

Why Tungsten Carbide Excels in Hygienic Environments

Tungsten carbide (WC) is a hard composite material consisting of tungsten and carbon, often bonded with nickel or cobalt.

It combines the strength of a metal with the 硬度 of a ceramic, making it ideal for high-load, corrosion-prone, and high-temperature environments.

主なプロパティ:

Very high hardness (88–92 HRA) → resists abrasion from powders and liquids.

Smooth finish capability → allows for mirror-polished, sanitary surfaces.

高い 耐腐食性, especially with nickel-bonded grades.

Excellent thermal stability for hot cleaning cycles.

Low friction coefficient, reducing contamination and lubricant use.

For machinery that must meet FDA, GMP, or EHEDG standards, tungsten carbide’s inert surface helps prevent bacterial buildup and chemical reaction with food or pharmaceutical products.

Comparison with Common Bushing Materials

| 材料 | 耐腐食性 | 耐摩耗性 | Hygienic Finish | Service Life |

|---|---|---|---|---|

| ステンレス鋼 | 良い | 中くらい | 良い | 中くらい |

| Polymer (PTFE, PEEK) | 素晴らしい | 低い | 素晴らしい | 短い |

| タングステンカーバイド | 素晴らしい | 並外れた | Mirror Polish Possible | Very Long |

This table shows why tungsten carbide outperforms both steel and polymer options — especially when durability and cleanliness must coexist.

Applications in Food Processing Equipment

| Machine Type | Operating Conditions | Function of Bushing |

|---|---|---|

| Mixers and Blenders | High torque and moisture | Provides low-friction support for rotating shafts |

| Pumps and Fillers | Frequent cleaning, exposure to acids | Prevents corrosion and extends life cycle |

| Conveyors and Packaging Lines | Continuous motion, humidity | Maintains smooth motion with minimal wear |

In food production, tungsten carbide bushings are ideal for parts exposed to constant washing, high load, or friction — keeping production lines running longer without contamination risks.

Applications in Pharmaceutical Equipment

| Equipment | 状態 | Bushing Function |

|---|---|---|

| Tablet Compressors | Powder friction and pressure | Prevents wear and maintains uniform compression |

| Centrifuges | High-speed rotation | Provides precision alignment and stability |

| Filling and Packaging Machines | Continuous operation under cleanroom conditions | Ensures long-lasting, smooth motion with low friction |

Pharmaceutical equipment demands absolute cleanliness and dimensional accuracy.

タングステンカーバイドブッシング meet these needs while maintaining surface polish to prevent material sticking or cross-contamination.

Nickel-Bonded vs Cobalt-Bonded Carbide

| バインダータイプ | 耐腐食性 | 強靭さ | Recommended Use |

|---|---|---|---|

| Cobalt-Bonded Carbide | 適度 | 高い | High mechanical load areas (mixers, bearings) |

| ニッケル結合炭化物 | 素晴らしい | 良い | Corrosive or food-contact applications |

Nickel-bonded tungsten carbide is most popular in food and pharmaceutical systems due to its chemical inertness and non-reactive surface with cleaning agents.

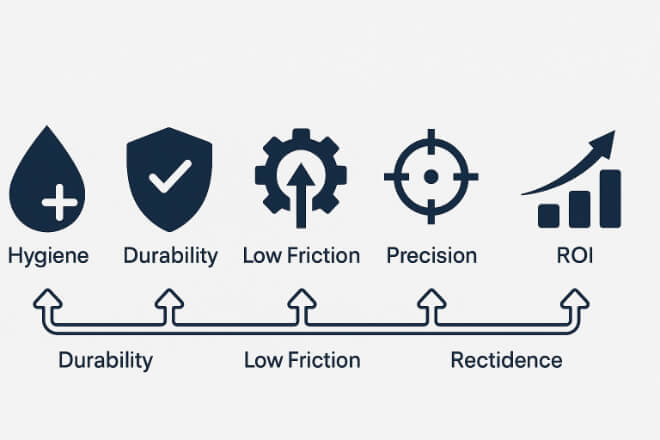

Benefits for Food and Pharmaceutical Equipment Designers

Longer lifespan in high-moisture, high-cleaning environments.

Reduced contamination risks through smoother, cleaner surfaces.

Lower friction and minimal lubricant requirements.

Dimensional stability under heat and pressure.

Lower maintenance frequency, reducing downtime.

By upgrading to タングステンカーバイドブッシング, equipment builders can guarantee longer service intervals and safer, cleaner operations.

結論

In industries where cleanliness, safety, and reliability are non-negotiable, tungsten carbide bushings deliver unmatched performance.

Their hardness, polishability, and corrosion resistance make them the best choice for food and pharmaceutical applications where downtime and contamination are unacceptable.

For manufacturers and engineers, adopting tungsten carbide bushings means higher productivity, improved hygiene compliance, and better ROI through reduced maintenance costs.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。