タングステンカーバイドブッシング are essential components used in various industrial applications, particularly in demanding environments like 採掘, pumps, and automotive systems.

These bushings are known for their durability, 耐摩耗性, and ability to handle high-pressure and high-temperature conditions.

However, like any industrial material, tungsten carbide eventually wears out and needs to be replaced.

The good news is that recycling tungsten carbide bushings offers a powerful solution to reduce both waste and costs.

In this article, we will explore how recycling helps minimize environmental impact, reduces the demand for new raw materials, and results in significant cost savings for companies.

Why Recycling Tungsten Carbide Bushings Is Important

Tungsten carbide is made from tungsten, a rare and valuable metal, and carbon, which is combined to form an extremely hard and durable material.

As industries continue to use tungsten carbide bushings in high-stress applications, they inevitably wear down over time.

Instead of discarding these worn-out parts, recycling allows businesses to reclaim valuable materials and extend the lifecycle of tungsten carbide.

Recycling tungsten carbide bushings helps in several ways:

Reduces the demand for new tungsten mining, a process that requires substantial energy and resources.

Minimizes waste by repurposing worn-out components, keeping them out of landfills.

Saves money by cutting down on material costs and avoiding the need to purchase fresh tungsten carbide.

Supports sustainability initiatives, as recycling reduces CO₂ emissions and energy consumption compared to primary tungsten production.

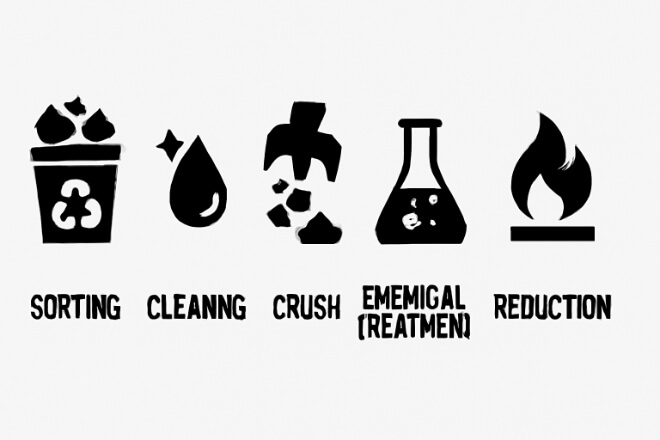

The Recycling Process of Tungsten Carbide Bushings

The recycling process for tungsten carbide bushings involves a few key steps, aimed at recovering the valuable tungsten and other materials that can be reused in manufacturing.

Step 1: Collection of Worn Bushings

Worn-out bushings are collected from various industrial applications. Companies often have a scrap collection program where customers or maintenance teams can return used bushings for recycling.

Step 2: Sorting and Cleaning

Once collected, the bushings are sorted based on their grade and binder content (e.g., cobalt or nickel).

They are then cleaned to remove any oils, dirt, or other contaminants that could affect the recycling process.

Step 3: Crushing and Pulverizing

The cleaned bushings are broken down into fine powder through mechanical crushing.

This helps to expose the tungsten carbide grains, allowing them to be efficiently separated during the next steps.

Step 4: Chemical Treatment

At this stage, the powder undergoes a chemical treatment to separate the tungsten from the binder material.

Cobalt, nickel, and other binders are typically removed, leaving behind pure tungsten carbide powder.

Step 5: Refining and Reduction

The remaining tungsten carbide is then refined through a process known as reduction, where it is exposed to heat and gases to restore its metallic form.

This process results in high-purity tungsten powder, which can be reused in new carbide production.

Step 6: Reuse in Manufacturing

The recycled tungsten carbide powder is blended with fresh materials to create new tungsten carbide parts, including bushings, tools, and other industrial components.

Benefits of Recycling Tungsten Carbide Bushings

Recycling tungsten carbide bushings offers several environmental and economic benefits for businesses, including:

1). Environmental Benefits

Reduced mining and extraction: Recycling tungsten reduces the need for mining new tungsten ore, which requires energy-intensive processes and contributes to environmental degradation.

Energy savings: Recycling tungsten carbide uses significantly less energy compared to the production of new material, reducing the overall carbon footprint.

Decreased waste generation: By recycling worn bushings, companies can reduce industrial waste and contribute to a circular economy.

2). Cost Savings

Lower material costs: Recycled tungsten is much cheaper than newly mined tungsten, offering businesses significant savings when purchasing raw materials.

Reduced production costs: As the recycled material can be directly reused in manufacturing, companies can reduce expenses related to sourcing and processing new tungsten.

Buy-back programs: Many suppliers offer buy-back programs for scrap tungsten carbide, providing companies with an additional revenue stream for their used parts.

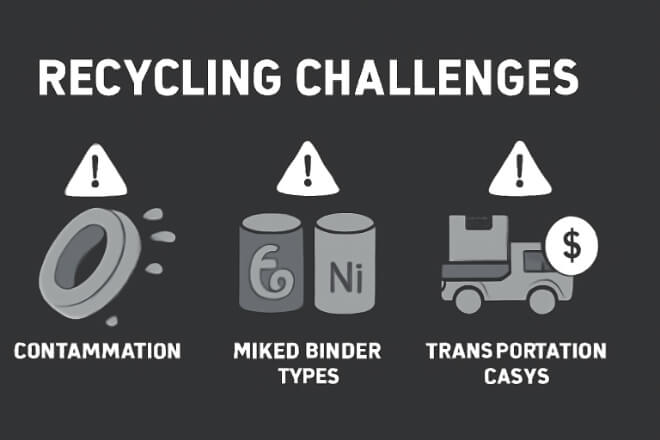

Challenges of Recycling Tungsten Carbide Bushings

While there are clear benefits, recycling tungsten carbide does come with its challenges:

Contamination: Tungsten carbide parts may be contaminated with oils, metals, or other substances, making it difficult to extract pure tungsten.

Mixed binder types: タングステンカーバイドブッシング can be made with different binder materials (e.g., cobalt or nickel), which require separate processing.

Processing costs: The recycling process, including chemical treatment and refining, can be costly, especially when dealing with mixed materials or complex parts.

Transportation: Tungsten carbide is heavy and dense, so transporting scrap parts to recycling facilities can be expensive.

Despite these challenges, the environmental and financial benefits of recycling tungsten carbide far outweigh the costs, making it a valuable practice for sustainable business operations.

How Businesses Can Benefit from Tungsten Carbide Recycling

For decision-makers, implementing a tungsten carbide recycling program can be a highly effective way to lower operational costs while improving sustainability. Companies can:

Set up internal recycling systems to collect used bushings and scrap parts.

Partner with specialized recyclers that can efficiently separate, refine, and reuse the materials.

Integrate recycled materials back into production processes to reduce reliance on raw materials.

Promote environmental responsibility by aligning with sustainability initiatives and green practices, which can improve company branding and customer loyalty.

結論

Recycling tungsten carbide bushings is a smart and sustainable solution that offers both environmental and financial advantages.

By reusing valuable tungsten and reducing the need for new material, businesses can save money, improve their sustainability credentials, and help protect the planet.

With rising demand for sustainable practices and resource conservation, incorporating tungsten carbide recycling into your operations is a win-win strategy for both cost-efficiency and environmental responsibility.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。