タングステンカーバイドブッシング are a vital component in many industries, offering high 耐摩耗性 and durability in demanding environments.

However, as technology evolves, so do the materials used to make tungsten carbide bushings.

With new innovations, manufacturers can now produce even more efficient, long-lasting, and eco-friendly bushings.

In this post, we’ll explore some of the latest advances in tungsten carbide bushing materials that are transforming industries such as mining, oil and gas, automotive, and chemical processing.

New Binder Systems for Enhanced Performance

Historically, cobalt has been the go-to binder for tungsten carbide due to its strength and 強靭さ.

But new binder systems are making waves in improving performance under specific conditions.

Nickel-Bonded Tungsten Carbide:

Known for its 耐腐食性, nickel-bonded tungsten carbide is becoming a popular choice for industries dealing with harsh chemicals and marine environments.

Dual Binder Systems:

Combining cobalt and nickel or cobalt and iron offers better balance between wear resistance and corrosion resistance, making them ideal for high-demand applications.

Cobalt-Free Options:

With environmental concerns on the rise, cobalt-free binder systems are gaining traction, offering similar durability without relying on cobalt, which has a volatile price and environmental impact.

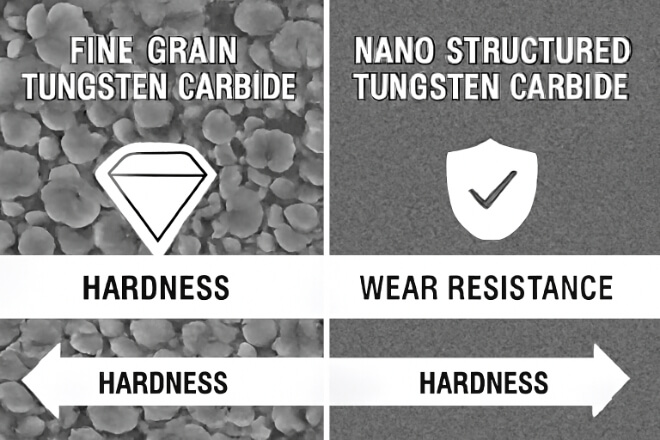

Microstructure Designs for Improved Performance

The microstructure of tungsten carbide affects how well it performs under stress, wear, and heat.

By controlling the grain size and structure, manufacturers can create materials with specific properties to suit the needs of various industries.

Fine-Grain Tungsten Carbide:

Smaller grains make the material harder and more 耐摩耗性, which is crucial in high-speed and high-precision applications.

Nano-Structured Tungsten Carbide:

This advanced material offers even finer grains, improving strength and wear resistance in extreme conditions like those found in drilling or mining.

Gradient Microstructures:

Combining varying hardness levels within the same material helps the bushings perform better in both abrasive and impact environments, such as in heavy machinery.

Coatings and Surface Treatments for Tungsten Carbide Bushings

To enhance the durability and performance of tungsten carbide bushings, coatings and surface treatments are applied.

These coatings can improve properties like 耐腐食性, friction reduction, and wear resistance.

Diamond-Like Carbon (DLC) Coatings:

DLC coatings help reduce friction and improve the hardness of tungsten carbide bushings, making them ideal for high-speed and dry running applications.

Ceramic Coatings:

Coatings like TiN (Titanium Nitride) and CrN (Chromium Nitride) provide extra wear protection and corrosion resistance, especially in high-temperature environments.

Surface Texturing:

Texturing the surface of the bushing creates micro-pores that help retain lubrication, reducing wear and prolonging the life of the bushing in low-speed, high-load applications.

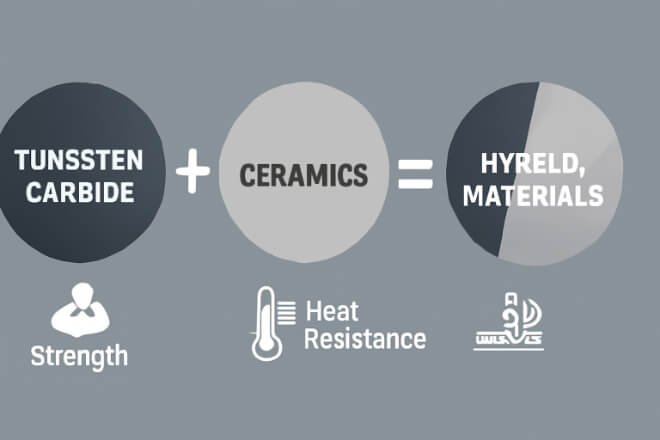

Hybrid and Composite Materials for Tungsten Carbide

Hybrid materials are gaining popularity in tungsten carbide bushings.

By combining tungsten carbide with other materials like ceramics or metals, manufacturers are able to achieve enhanced performance.

Carbide-Ceramic Hybrids:

Combining the hardness of tungsten carbide with the heat resistance of ceramics makes this material perfect for high-temperature chemical reactors.

Additive Manufacturing:

3D printing techniques have allowed manufacturers to create complex geometries for tungsten carbide bushings, offering solutions for custom applications that were previously not possible with traditional manufacturing methods.

Sustainability: Reducing Environmental Impact

Sustainability is becoming increasingly important in the manufacturing of tungsten carbide bushings.

To address environmental concerns, there have been advancements in recycling and reducing the use of harmful materials.

Recycling Tungsten Carbide:

One of the biggest advantages of tungsten carbide is that it can be easily recycled.

This helps reduce waste and the need for new materials, making it an eco-friendly choice for industries.

Cobalt-Free Materials:

Reducing or eliminating cobalt in the binder reduces environmental impact and makes tungsten carbide bushings more sustainable.

This also helps mitigate the volatility of cobalt prices and the associated supply chain risks.

結論

Recent innovations in tungsten carbide bushing materials are leading to products that offer enhanced performance, durability, and sustainability.

With advancements in binder systems, microstructures, coatings, and hybrid materials, manufacturers are better equipped to meet the demands of industries like oil and gas, mining, and chemical processing.

By embracing these innovations, businesses can improve efficiency, reduce maintenance costs, and contribute to a more sustainable future.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。