タングステンカーバイドブッシング are widely used across industries such as 採掘, 石油とガス, 航空宇宙、 そして 自動車 for their unmatched wear resistance and durability.

However, as demands for higher performance, longer life, and efficiency increase, the need for improved materials becomes ever more pressing.

One of the cutting-edge innovations in tungsten carbide technology is nanostructured tungsten carbide.

By modifying the structure of tungsten carbide at the nanoscale, manufacturers are creating bushings with superior properties, setting new standards in performance and longevity.

What Is Nanostructured Tungsten Carbide?

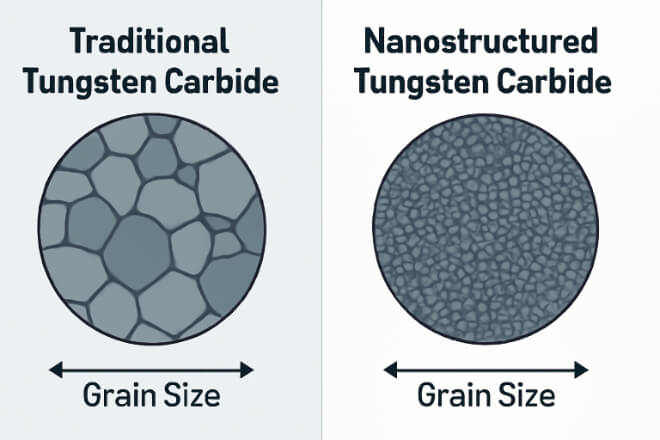

Nanostructured tungsten carbide is a form of tungsten carbide where the grains of the material are refined to the nanoscale level.

This means that the grains are much smaller than those in conventional tungsten carbide.

The reduction in grain size improves the material’s properties, such as strength, 硬度、 そして 耐摩耗性.

Through advanced manufacturing techniques like powder metallurgy and hot isostatic pressing, tungsten carbide can be transformed into a nanostructured material with a uniform, fine grain structure.

The smaller grains enhance the 密度 of the material, which leads to a more durable and wear-resistant product, making it highly suitable for use in bushings that endure extreme wear and high stress.

Nanostructured Tungsten Carbide vs. Conventional Tungsten Carbide

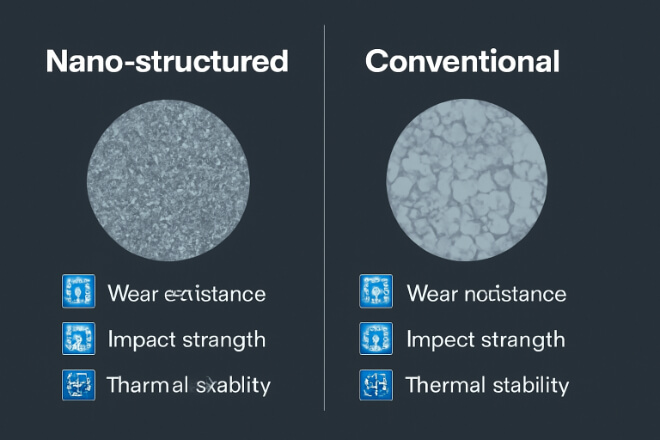

The primary difference between nanostructured tungsten carbide and conventional tungsten carbide lies in the grain size and the material’s overall 強靭さ.

While both offer outstanding 硬度, nanostructured tungsten carbide brings additional advantages, especially in applications that involve abrasive or high-temperature environments.

Here’s a comparison:

| 財産 | Nanostructured Tungsten Carbide | Conventional Tungsten Carbide |

|---|---|---|

| 粒度 | Smaller (nano-sized grains) | Larger (micron-sized grains) |

| 硬度 | Higher due to fine grain structure | High but lower than nanostructured |

| 耐摩耗性 | Enhanced, longer lifespan | Excellent, but less than nano |

| Impact Resistance | Higher due to improved toughness | Strong, but more prone to cracking |

| 耐熱性 | Superior at extreme temperatures | Very good, but less than nano |

Benefits of Nanostructured Tungsten Carbide in Bushing Design

The introduction of nanostructured tungsten carbide into bushing design brings several benefits that enhance performance, durability, and cost-efficiency:

1). Increased 耐摩耗性

Nanostructured tungsten carbide has much smaller grains than traditional tungsten carbide, which allows for a denser structure.

This dense microstructure makes it much more resistant to abrasive wear, reducing the rate of material degradation in high-friction environments.

Key Benefit: Longer bushing life, reducing the frequency of replacements and minimizing downtime in machinery.

2). Improved Impact Resistance

Bushings made from nanostructured tungsten carbide can better withstand impacts and vibrations compared to traditional bushings.

This is especially beneficial in industries like mining and construction, where equipment faces frequent shocks and extreme pressure.

Key Benefit: Reduced risk of failure in challenging operating conditions.

3). Enhanced Thermal Stability

Nanostructured tungsten carbide has improved thermal stability, allowing it to perform effectively in high-temperature applications such as 航空宇宙 or oil drilling.

This increased heat resistance prevents the bushing from expanding or losing its shape, even under extreme temperature fluctuations.

Key Benefit: Greater reliability in high-temperature environments.

4). Reduced Friction and Energy Loss

Thanks to its fine grain structure, nanostructured tungsten carbide exhibits lower friction when in contact with other surfaces.

This results in reduced energy loss due to friction, contributing to improved efficiency in machinery and lowering operational costs.

- Key Benefit: Energy savings and more efficient performance in equipment.

Applications of Nanostructured Tungsten Carbide Bushings

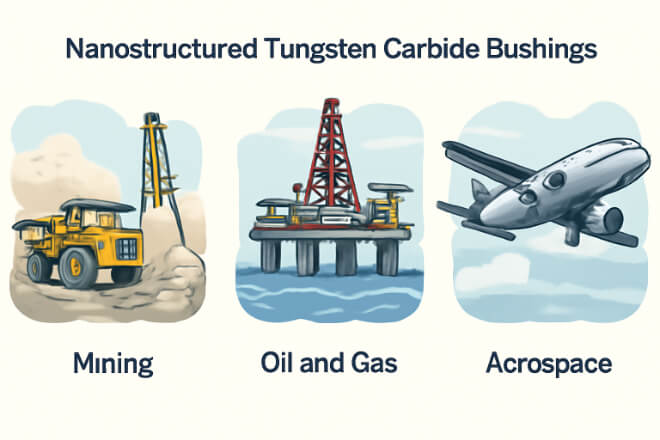

Due to their superior performance characteristics, nanostructured tungsten carbide bushings are now being used in various demanding industries:

Mining: For use in mining equipment like drills and crushers where wear and impact are constant concerns.

石油とガス: For bushings in pumps, compressors, and other drilling equipment that endure extreme pressures and abrasive conditions.

航空宇宙: Where high-temperature resistance and strength are critical for components like turbines and engines.

自動車: In high-performance vehicles where parts are subjected to wear and friction, improving the efficiency and lifespan of the vehicle.

Nanostructured tungsten carbide bushings are ideal for applications where extreme conditions are prevalent, and reliability is crucial.

Future Innovations in Nanostructured Tungsten Carbide

The development of nanostructured tungsten carbide is still evolving.

Researchers are continually working to refine its properties and discover new ways to enhance its performance. Future innovations may include:

Improved Manufacturing Techniques: To further reduce costs and make nanostructured tungsten carbide more accessible.

Hybrid Materials: Combining nanostructured tungsten carbide with other materials, such as ceramics or advanced polymers, for even better wear resistance and performance.

Environmentally Friendly Options: Developing cobalt-free or low-cobalt versions of nanostructured tungsten carbide to make it more sustainable.

結論

Nanostructured tungsten carbide is significantly changing the landscape of bushing design, offering enhanced performance in abrasive, high-stress, and high-temperature environments.

With its superior wear resistance, impact strength, and thermal stability, this material is poised to become the preferred choice in industries such as mining, oil and gas, and aerospace.

As the technology continues to evolve, nanostructured tungsten carbide bushings will likely play an increasingly important role in the future of machinery design and maintenance.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。