次のような業界では 採掘, 石油・ガス、 そして 航空宇宙, machinery is often subjected to extreme conditions—high temperatures, pressures, and abrasive materials.

To address these challenges, hybrid tungsten carbide composites are becoming increasingly popular.

By combining tungsten carbide with other materials, these composites offer exceptional durability, 耐摩耗性、 そして 強靭さ.

This article will explore the advantages of hybrid tungsten carbide composites for extreme environments and what decision-makers need to know.

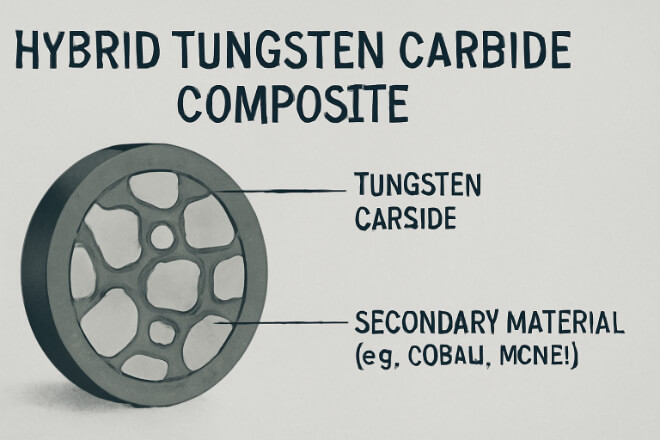

What Are Hybrid Tungsten Carbide Composites?

Hybrid tungsten carbide composites are materials made by combining tungsten carbide (WC) with other materials like cobalt, nickel, or ceramics.

The base material, tungsten carbide, is known for its 硬度 そして 耐摩耗性, but adding other elements enhances its 強靭さ, impact resistance, and performance in extreme conditions.

These composites are specially designed for use in demanding applications, offering the best of both worlds: the hardness of tungsten carbide and the strength of the added material.

Why Hybrid Tungsten Carbide Composites Are Ideal for Extreme Conditions

Hybrid tungsten carbide composites are engineered for use in harsh environments where standard materials would fail.

Here are some of the key reasons why they are ideal for extreme conditions:

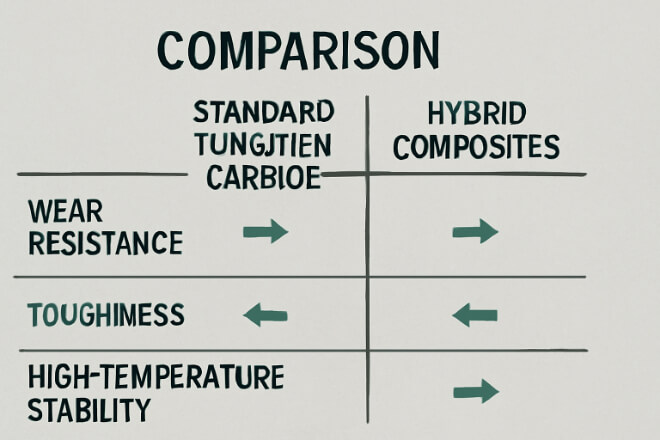

Enhanced 耐摩耗性:

Tungsten carbide is well-known for its wear resistance, but when combined with cobalt or ceramics.

The composite can withstand even more aggressive environments like high-pressure systems or abrasive surfaces.

改善された 強靭さ:

Pure tungsten carbide is extremely hard but brittle.

By adding materials like cobalt or nickel, the composite becomes more flexible and resistant to fractures, while maintaining its hardness.

High-Temperature Stability:

Some hybrid composites maintain their properties even at elevated temperatures.

This makes them ideal for aerospace applications or industries like power generation where high temperatures are common.

Example: In the mining industry, hybrid tungsten carbide composites are used for tools that must resist abrasion from rock and soil while maintaining structural integrity in high-impact conditions.

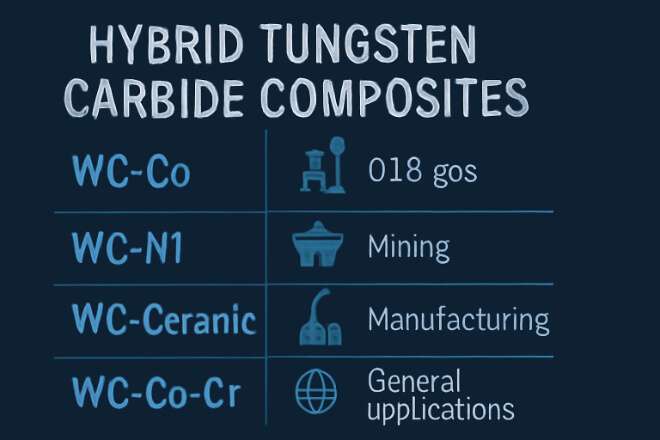

Types of Hybrid Tungsten Carbide Composites and Their Applications

There are various types of hybrid tungsten carbide composites, each tailored for specific industrial needs:

WC-Co Composites:

The combination of tungsten carbide and cobalt is one of the most common.

It provides a balance of 硬度 そして 強靭さ, making it ideal for cutting tools, 採掘, and machining operations.

WC-Nickel (WC-Ni) Composites:

These composites offer superior resistance to heat and corrosion, making them useful in high-temperature applications like gas turbines and heat exchangers.

WC-Ceramic Composites:

Adding ceramics like titanium carbide (TiC) or tantalum carbide (TaC) enhances the 耐摩耗性 of tungsten carbide, which is ideal for applications in military and 航空宇宙 industries where extreme hardness is required.

WC-Co-Cr Composites:

These are designed for environments where both high abrasion and 耐腐食性 are needed.

Such as in the oil and gas industry, particularly for drill bits.

Table: Comparison of Hybrid Tungsten Carbide Composites

| Composite Type | Materials | Key Benefit | アプリケーション |

|---|---|---|---|

| WC-Co | Tungsten Carbide & Cobalt | バランスの取れた硬度と靭性 | Cutting tools, mining, machining |

| WC-Nickel | Tungsten Carbide & Nickel | High heat and corrosion resistance | Aerospace, turbines, heat exchangers |

| WC-Ceramic | Tungsten Carbide & Ceramics (TiC, TaC) | High hardness and wear resistance | Military, aerospace |

| WC-Co-Cr | Tungsten Carbide, Cobalt & Chromium | Abrasion and corrosion resistance | Oil & gas, drilling tools |

Key Benefits of Hybrid Tungsten Carbide Composites for Extreme Conditions

Using hybrid tungsten carbide composites offers several key benefits:

長寿命:

These composites can withstand extreme wear and high temperatures, leading to a longer service life for components like cutting tools, machinery parts, and drill bits.

費用対効果:

Although hybrid composites may have a higher initial cost, their durability reduces the need for frequent replacements and maintenance, leading to significant cost savings in the long run.

安全性の向上:

With their enhanced 強靭さ そして resistance to fractures, hybrid composites ensure greater safety in operations, reducing the risk of equipment failure in critical situations.

Better Performance in Harsh Environments:

Hybrid composites perform well in extreme conditions, including exposure to abrasives, high temperatures.

And corrosive environments, making them versatile across industries.

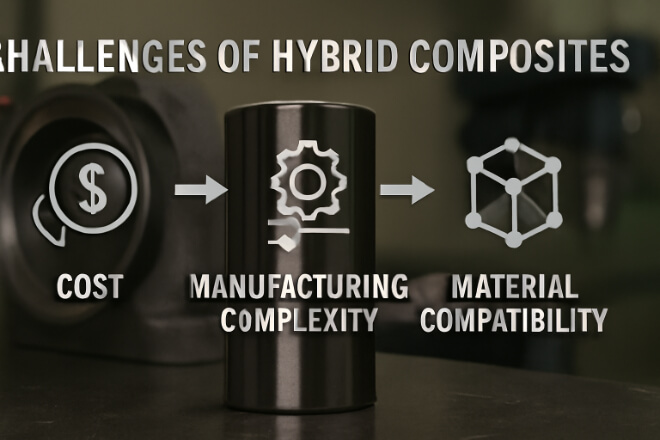

Challenges and Considerations When Using Hybrid Tungsten Carbide Composites

Despite their benefits, hybrid tungsten carbide composites come with a few challenges:

料金:

Hybrid composites tend to be more expensive than standard tungsten carbide, which can be a concern for companies with tight budgets.

However, their longer lifespan and reduced maintenance costs can offset this initial investment.

Complex Manufacturing:

Producing hybrid composites requires specialized equipment and techniques.

The process may involve high precision to ensure optimal performance.

Material Compatibility:

It’s essential to select the right secondary material for the composite.

Not all materials bond well with tungsten carbide, and poor bonding can compromise the composite’s properties.

結論

Hybrid tungsten carbide composites offer a solution for industries that operate in extreme conditions.

By combining the durability of tungsten carbide with the toughness and heat resistance of other materials, these composites provide superior performance in applications such as mining, aerospace, and oil & gas.

While they may come at a higher initial cost, the long-term benefits—reduced downtime, improved safety.

And extended service life—make them a valuable investment for industries requiring high-performance materials.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。