タングステンカーバイドブッシング are highly durable and widely used in various industrial applications that demand high 耐摩耗性 そして 強靭さ.

However, even the toughest materials can experience performance issues if not properly installed and maintained.

Misalignment and vibration are two common problems that can significantly impact the performance of tungsten carbide bushing systems.

In this blog, we’ll explore the causes of misalignment and vibration, how they affect bushing systems, and the best practices for preventing them to ensure optimal performance and longevity of your equipment.

What is Misalignment in Bushing Systems?

Misalignment occurs when the shaft and housing are not properly aligned, causing uneven pressure on the bushing during operation.

This misalignment can lead to several issues, including excessive wear, overheating, and premature bushing failure.

1). Causes of Misalignment:

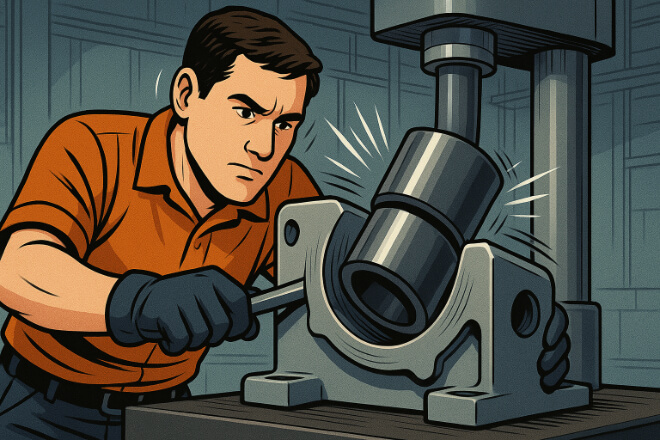

Improper Installation: Incorrect assembly during installation can cause the shaft and housing to be misaligned.

Wear Over Time: Over time, components may shift or wear out, leading to misalignment.

Manufacturing Defects: In some cases, the housing or shaft may not be manufactured to the correct dimensions, resulting in misalignment.

2). Effects of Misalignment:

Increased Friction: Misalignment causes uneven pressure on the bushing, which increases friction and leads to excess heat generation. This heat can accelerate wear and reduce the bushing’s lifespan.

Uneven Wear: Misalignment causes uneven load distribution, leading to localized wear on the bushing. This uneven wear can cause cracks, chips, and other forms of damage.

Reduced Performance: Misalignment negatively impacts the efficiency of the system, causing energy loss and reduced operational capacity.

3). Solution:

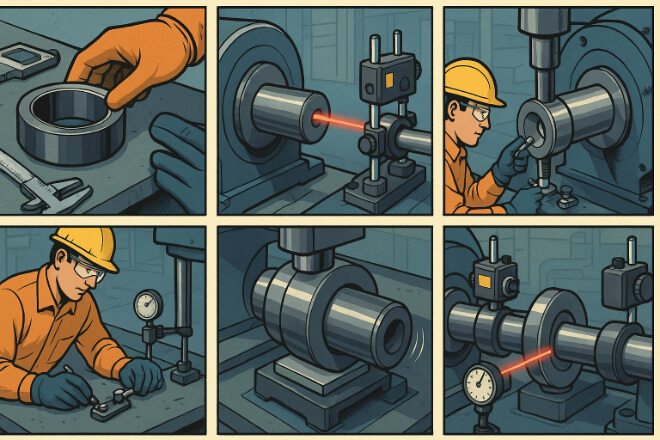

Precision Alignment Tools: Use precision alignment tools like laser alignment systems, dial indicators, or alignment jigs during installation to ensure the shaft and housing are perfectly aligned.

Regular Inspections: Periodically inspect the alignment of the shaft and housing to detect any misalignment caused by wear over time.

Correct Fit Tolerances: Ensure the bushing, shaft, and housing are manufactured to the correct specifications and tolerances to prevent misalignment from the outset.

What is Vibration in Bushing Systems?

Vibration is another common issue in bushing systems that can lead to premature wear and failure of tungsten carbide bushings.

Vibration can occur due to misalignment, excessive loads, or mechanical imbalances in the system.

1). Causes of Vibration:

Unbalanced Loads: If the load applied to the bushing system is uneven or fluctuates, it can cause vibration. This is common in high-speed applications where the load changes rapidly.

Misalignment: As mentioned earlier, misalignment between the shaft and housing can cause vibration, as the uneven fit leads to uneven pressure distribution.

Mechanical Imbalances: If any of the components in the system, such as the shaft or housing, are damaged or improperly installed, they can cause imbalances that lead to vibration.

2). Effects of Vibration:

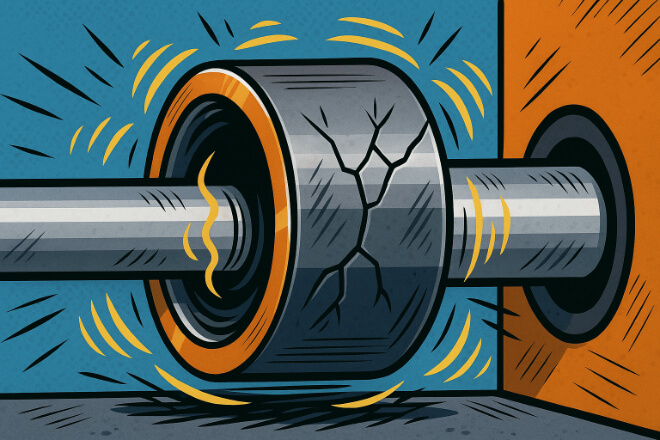

Increased Wear: Vibration increases friction and causes stress on the bushing, which accelerates wear and can lead to premature failure.

Fatigue Damage: Continuous vibration can cause fatigue damage to the bushing material, leading to cracks or fractures over time.

Noise and Reduced Efficiency: Vibration generates noise and reduces the overall efficiency of the system, making it less reliable and cost-effective.

3). Solution:

Balance the System: Ensure that the shaft, housing, and other components are balanced and free from defects. Regularly check for signs of wear or damage that could cause imbalance.

Damping Materials: Use damping materials, such as rubber or synthetic components, to absorb vibrations and reduce the impact on the bushing.

Proper Installation: Install components carefully to ensure that they are aligned and balanced, preventing the causes of vibration from developing.

Best Practices for Preventing Misalignment and Vibration

1). Use Precision Alignment Tools

Using precise tools to measure and adjust the alignment of the shaft and housing is the most effective way to prevent misalignment.

Laser alignment systems are especially useful for achieving high precision and ensuring that all components are correctly aligned before installation.

Benefits: Laser systems provide real-time feedback and allow for quick adjustments, ensuring a perfect fit.

Regular Checks: Even after installation, use alignment tools to periodically check for misalignment as wear and tear can shift components over time.

2). Proper Installation and Handling

During installation, ensure that all components are properly handled and installed according to manufacturer guidelines.

Avoid dropping or mishandling components, as this can cause damage that leads to misalignment or imbalance.

Support Jigs: Use support jigs or fixtures to hold the shaft, housing, and bushing in place during installation, ensuring a consistent and accurate fit.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommended installation procedures to avoid mistakes that can lead to misalignment.

3). Regular Maintenance and Inspections

Routine maintenance is key to preventing misalignment and vibration. Regularly check for signs of wear, imbalance, or misalignment in the system.

This will help you identify potential issues early before they lead to more serious damage.

Lubrication Checks: Ensure that the bushing and mating components are properly lubricated to reduce friction and wear.

Wear Monitoring: Inspect the bushing for signs of uneven wear, cracking, or damage. Address any issues immediately to prevent further deterioration.

4). Addressing Vibration with Damping Solutions

Vibration can be minimized by using damping materials such as rubber mounts or synthetic polymers. These materials absorb vibrations and reduce their impact on the system.

Vibration Dampers: Install vibration dampers in areas where vibration is most likely to occur, such as at mounting points or along the shaft.

Regular Vibration Monitoring: Use vibration sensors to monitor the system during operation and identify any unusual vibrations that could indicate misalignment or imbalance.

Common Causes of Misalignment and Vibration

| Cause | Effect | Solution |

|---|---|---|

| Misalignment | Increased friction, uneven wear, cracking | Use precision alignment tools, regular inspections |

| Excessive Load | Stress concentration, deformation, wear | Monitor load limits, use appropriately rated bushings |

| Vibration | Wear, fatigue, noise, inefficiency | Use damping materials, balance the system |

結論

Misalignment and vibration can significantly reduce the performance and lifespan of tungsten carbide bushing systems.

By implementing best practices such as using precision alignment tools, proper installation techniques, and regular maintenance, you can prevent these issues and ensure optimal system performance.

Additionally, addressing vibration with damping materials and balancing components can further enhance the longevity and efficiency of your equipment.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ.