タングステンカーバイドブッシング are essential components in pumps, offering high resistance to wear, heat, and corrosion.

They are used in various industries, including 石油とガス, chemical processing, and water treatment. However, even the toughest materials require regular maintenance to ensure optimal performance and longevity.

In this blog, we will outline a simple and effective maintenance checklist for pump bushings made of tungsten carbide.

This checklist will help you maintain the integrity of your pump systems, reduce downtime, and extend the life of the bushings.

List 1: Regular Inspection for Wear and Tear

One of the most important steps in maintaining tungsten carbide bushings is regular inspection.

Over time, the bushings may experience wear due to friction, high pressure, or corrosive fluids. Early detection of wear can prevent further damage and costly repairs.

1). What to Look For:

Surface Damage: Check for cracks, chips, or grooves on the bushing surface. These are signs of excessive wear or improper installation.

Dimensional Changes: Measure the bushing’s outer diameter and compare it to the manufacturer’s specifications. Any increase in diameter may indicate wear, which could lead to misalignment or failure.

Wear Patterns: Look for uneven wear patterns, which may suggest misalignment or excessive friction.

2). How to Inspect:

Use precision measuring tools such as micrometers or calipers to check the dimensions of the bushing.

Perform visual checks for cracks, chips, or surface roughness. Magnification tools may be necessary for small defects.

List 2: Check Alignment and Fit

Misalignment is a common cause of premature wear in pump bushings.

When the shaft and housing are not properly aligned, the bushing experiences uneven pressure and friction, which can lead to accelerated wear and failure.

Ensuring proper alignment is crucial to extending the life of the bushing.

1). What to Check:

Shaft and Housing Alignment: Ensure the shaft is aligned with the housing. Misalignment can cause localized wear on the bushing and lead to cracking or chipping.

Fit Between Bushing and Housing: The fit between the bushing and housing should not be too tight or too loose. A tight fit can create excessive friction, while a loose fit can cause movement and vibration, leading to wear.

2). How to Check Alignment:

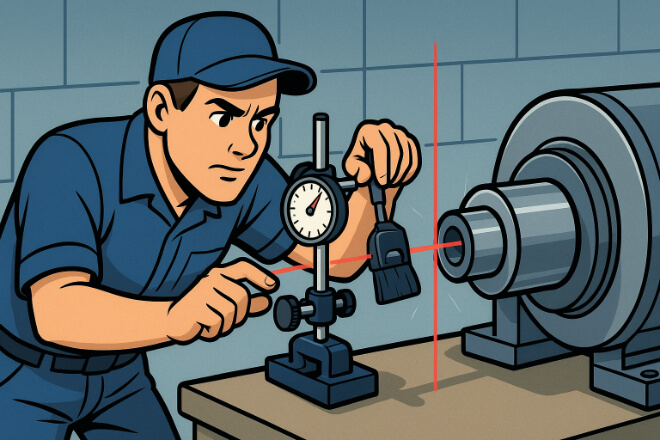

Use laser alignment tools or dial indicators to ensure the shaft and housing are properly aligned.

Measure the clearance between the bushing and housing to ensure a proper fit.

List 3: Monitor Lubrication Levels

Lubrication is essential for reducing friction and preventing wear. タングステンカーバイドブッシング operate most efficiently when properly lubricated.

Insufficient lubrication can cause excessive heat buildup, leading to material degradation and failure.

1). What to Monitor:

Lubricant Type: Use the recommended lubricant for tungsten carbide bushings. Ensure that the lubricant is compatible with the pump’s operating conditions, including temperature, load, and type of fluid being pumped.

Lubrication Frequency: Make sure that the bushing is lubricated at the correct intervals. Over-lubrication can attract debris, while under-lubrication increases friction.

Lubricant Quality: Check for signs of contamination, such as particles or dirt, which can cause wear and tear on the bushing.

2). How to Monitor:

Set up a regular schedule for lubricating the bushing, based on the manufacturer’s recommendations and operating conditions.

Use lubrication systems with sensors that monitor lubricant levels and quality to ensure optimal performance.

List 4: Check for Contamination and Corrosion

Contamination of the lubricant or the pump fluid can cause premature wear and damage to the tungsten carbide bushing.

Corrosive fluids, dirt, or other particles can damage the bushing surface and affect its performance.

1). What to Look For:

Corrosion: Check for signs of corrosion, especially if the pump is used with abrasive or corrosive fluids. Corrosion can weaken the bushing and lead to cracks or breakage.

Debris and Particles: Examine the lubricant and the pump fluid for debris or particles that could cause abrasive wear on the bushing surface.

2). How to Prevent Contamination:

Install filters in the pump system to remove contaminants from the fluid.

Use seals and gaskets to prevent the ingress of contaminants into the bushing and lubrication system.

List 5: Regular Cleaning and Maintenance of the Pump System

Cleaning and maintaining the entire pump system is vital to prevent issues that can affect the tungsten carbide bushing.

Dirt, debris, and buildup can cause improper operation, leading to bushing failure.

1). What to Clean:

Pump Housing: Clean the housing to ensure it is free from dirt, rust, or debris that could affect the bushing’s performance.

Shaft: Inspect and clean the shaft to ensure there is no buildup that could damage the bushing or interfere with its movement.

Lubrication System: Clean and maintain the lubrication system, including the pumps, filters, and supply lines, to ensure that contaminants do not enter the bushing.

2). How to Clean:

Use non-abrasive cleaning solutions to avoid damaging the bushing or the shaft.

Regularly inspect and replace the pump seals to prevent leakage or contamination.

Maintenance Checklist for Tungsten Carbide Bushings

| Maintenance Task | 頻度 | 注記 |

|---|---|---|

| Inspect for Wear | 月次 | Look for cracks, chips, and surface damage |

| Check Alignment | Quarterly | Use alignment tools for accuracy |

| Monitor Lubrication | Bi-weekly | Ensure proper levels and quality |

| Check for Contamination | 月次 | Inspect fluid and lubricant for debris |

| Clean Pump System | Quarterly | Clean the housing, shaft, and lubrication system |

結論

Regular maintenance of tungsten carbide bushings is crucial to extend their life and maintain optimal pump performance.

By following a detailed maintenance checklist, including regular inspections, proper lubrication, and addressing misalignment or contamination, you can ensure your pump systems operate efficiently, reducing downtime and increasing the lifespan of the bushings.

Proper maintenance helps avoid costly repairs and ensures reliable pump operation.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。