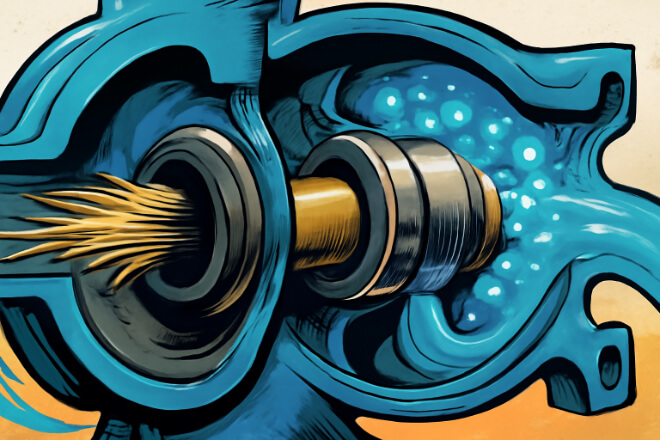

Pump ブッシング made of tungsten carbide work under high speed, high pressure, and aggressive fluids.

In these harsh conditions, two common failure modes appear again and again: erosion and cavitation damage. Both can cause early wear, vibration, leakage, and even shutdown of the pump.

This article explains how to detect these problems early, why they occur, and what signs decision-makers should watch for to protect their equipment and reduce downtime.

Understanding Erosion and Cavitation in Pump Bushings

Erosion and cavitation look similar at first glance, but they come from very different causes.

Understanding the difference helps engineers choose the right materials, improve operation conditions, and prevent damage before it becomes serious.

1). Erosion

Erosion occurs when high-velocity liquid or solid particles strike the bushing surface repeatedly.

Common causes include:

Dirty fluid with sand or hard particles

High flow velocity

Sharp directional changes inside the pump

Poor filtration systems

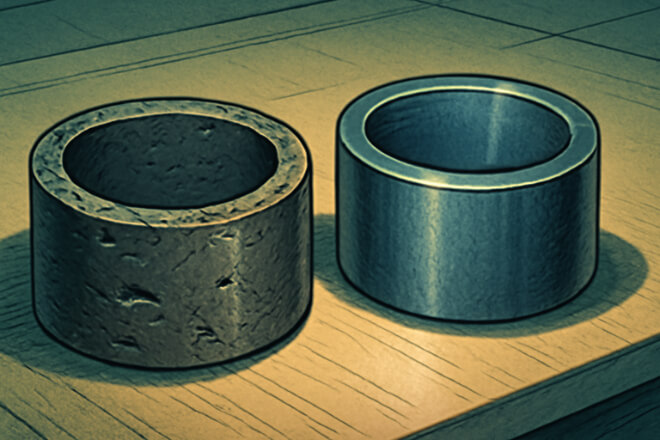

Erosion usually creates:

Smooth wear marks

Directional grooves

Gradual material loss

2). Cavitation

Cavitation happens when pressure drops inside the pump, forming vapor bubbles.

When these bubbles collapse near the bushing surface, they create tiny shock waves. Over time, these micro-explosions damage the material.

Cavitation damage usually creates:

Pitting

Small round holes

Rough, crater-like surface

Rapid material loss in local areas

Key Warning Signs of Erosion and Cavitation Damage

Below is a summary of how erosion and cavitation appear inside pumps:

| Type of Damage | Typical Appearance | Common Causes | リスクレベル |

|---|---|---|---|

| Erosion | Grooves, directional wear, smooth scars | High velocity, particles in liquid, poor filtration | Medium to High |

| Cavitation | Pitting, small round holes, crater patterns | Low inlet pressure, vapor bubbles, pump instability | High (rapid damage) |

Both issues can quickly lead to misalignment, friction, and leaks if not detected early.

Visual Inspection: First Step in Detecting Damage

A physical inspection of the bushing surface provides the fastest way to identify early-stage problems.

1). Signs of Erosion

Surface becomes smooth but heavily scratched

Wear follows the flow direction

Profile becomes out-of-round

Edges look thinner or tapered

2). Signs of Cavitation

Clusters of tiny pits

Rough, crater-like texture

Localized damage near inlet or low-pressure zones

Areas appear “eaten away”

Visual inspection should be done during:

Routine pump overhaul

Scheduled maintenance

After vibration alarms

When pump efficiency drops

Even without tools, an experienced engineer can identify many problems at this stage.

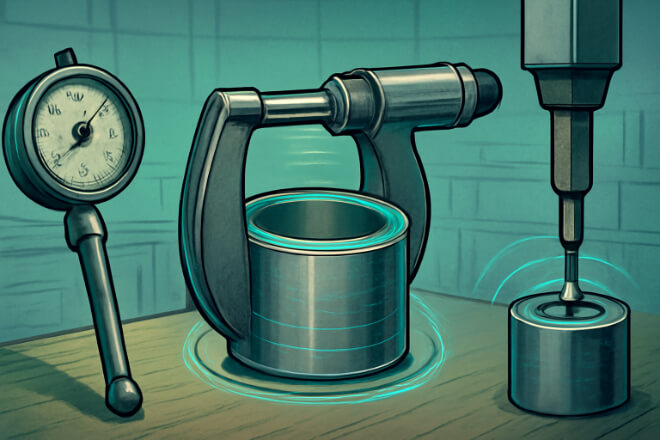

Measuring Dimensional Wear and Out-of-Round Conditions

Once visual signs appear, the next step is precise dimensional measurement.

1). Tools Used

Bore gauge

マイクロメーター

Coordinate Measuring Machine (CMM)

Roundness tester

2). Why It Matters

Pump bushings must maintain a constant clearance between shaft and housing. Too much wear from erosion or cavitation may cause:

Shaft instability

Excess vibration

Mechanical seal leaks

Faster wear on mating parts

3). Typical Tolerances

Roundness: Within 0.005–0.02 mm

Diameter deviation: Within ±0.002–0.005 mm (depending on pump design)

Dimensional checks help determine if the bushing can continue in service or needs replacement.

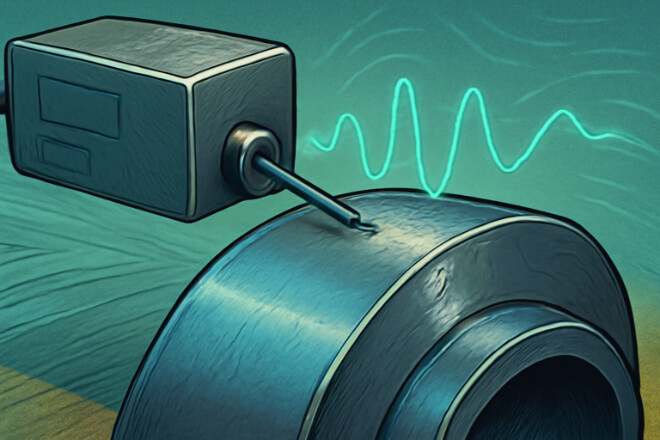

Using Surface Roughness Testing to Identify Early Damage

Surface roughness values reveal early degradation long before failure occurs.

1). Tools

Contact profilometer

Optical profilometer

2). Early Erosion Detection

Erosion increases surface roughness gradually over time. Typical safe Ra value for pump bushings:

Ra ≤ 0.2 µm for sliding bearing surfaces

When erosion starts:

Ra increases to 0.3–0.4 µm

Flow marks become more visible

Friction increases

3). Early Cavitation Detection

Cavitation creates rapid changes:

Ra jumps to 1.0 µm or higher

Sharp peaks appear in the roughness profile

Surface becomes “spiky”

Surface roughness testing can detect these changes weeks or months before total failure.

Non-Destructive Testing (NDT) for Hidden Damage

Some cavitation pits or erosion channels may not be visible to the naked eye. NDT methods help reveal internal or subsurface damage.

| Method | 最適な用途 | Damage Type | 利点 |

|---|---|---|---|

| 超音波検査(UT) | Internal defects | Deep cavitation pits, cracks | Fast and accurate |

| Dye Penetrant Inspection (DPI) | Surface defects | Micro-pitting, small cracks | Low cost |

| X-ray CT Scan | 3D analysis | Internal erosion channels | Highly detailed |

These tests help engineers detect early-stage damage that visual inspection may miss.

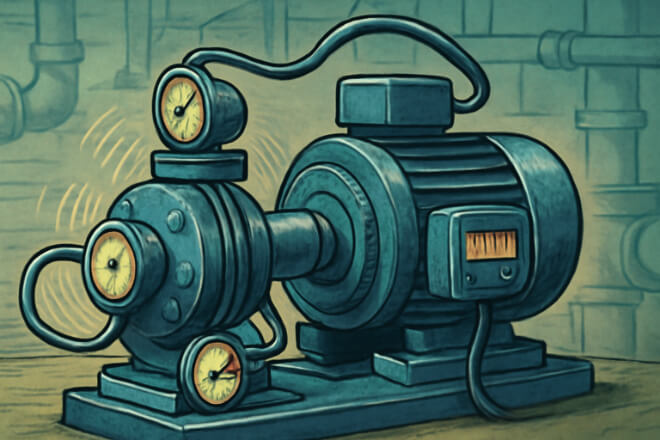

Monitoring Pump Performance to Detect Early Wear

Many early signs of erosion and cavitation appear not on the bushing itself, but in pump performance.

1). Key Indicators

Increase in vibration

Higher energy consumption

Reduced flow or pressure

Unstable operation

Noise caused by cavitation

Rising temperature around bearing housing

2). Why Decision-Makers Should Track These Indicators

These signals allow maintenance teams to predict failure before it happens.

Predictive monitoring reduces downtime, protects shafts and seals, and lowers repair costs.

When Should a Pump Bushing Be Replaced?

A bushing showing mild wear may still run safely, but deeper erosion or active cavitation requires action.

1). Replace Immediately If:

Cavitation pits cluster in critical load areas

Erosion removes more than 10–15% of wall thickness

Roundness is outside allowable tolerance

Ra exceeds recommended value

Vibration levels rise sharply

Pump becomes noisy or unstable

2). Why Quick Replacement Matters

Ignoring these signs can lead to:

Shaft scoring

Seal failure

Bearing seizure

Full pump breakdown

Replacing a damaged bushing is far cheaper than repairing a failed pump.

結論

Erosion and cavitation are two of the most common causes of pump bushing failure.

With the right inspection tools and monitoring methods, these issues can be detected early—long before they lead to downtime or costly repairs.

For decision-makers, investing in proper testing and early detection ensures longer equipment life, higher reliability, and lower maintenance costs.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。