For many OEMs and industrial companies, the first question when choosing bushings is not only performance, but total cost.

タングステンカーバイドブッシング have a higher purchase price than bronze, steel, polymer, or ceramic bushings. But the total cost over the full life cycle often tells a very different story.

This guide compares both options using simple, clear language to help decision-makers understand the real cost difference.

What “Total Cost” Really Means for Bushings

Many buyers focus only on the purchase price. But for critical rotating equipment, the real cost includes:

Purchase cost

Installation and labor

Downtime

Repair cost

交換頻度

Energy consumption

Long-term reliability

When all these factors are included, tungsten carbide often delivers lower overall cost—especially in pumps, compressors, mixers, and high-load systems.

Total Cost Components Table

| Cost Type | Impact on Budget | 注記 |

|---|---|---|

| Purchase Cost | Medium–High | Higher for tungsten carbide |

| メンテナンス | Low–High | Lower for carbide |

| Downtime | 高い | Usually highest hidden cost |

Comparing Material Performance

Material performance directly shapes life cycle cost. Tungsten carbide is extremely hard and 耐摩耗性, while conventional bushings use softer materials.

1). Common material types

Tungsten carbide (WC-Co or WC-Ni) – very hard, excellent 耐摩耗性

Bronze – soft, low cost, easy to machine

Stainless steel – strong but not highly wear resistant

Ceramic – hard but brittle

Polymer composite – low friction but limited load capacity

2). Performance Comparison Table

| 財産 | タングステンカーバイド | Conventional Bushings |

|---|---|---|

| 硬度 | 非常に高い | Low–Medium |

| ウェアライフ | 長さ | 短い |

| 耐薬品性 | 強い | 中くらい |

| 耐荷重 | 高い | Low–Medium |

Cost of Maintenance and Downtime

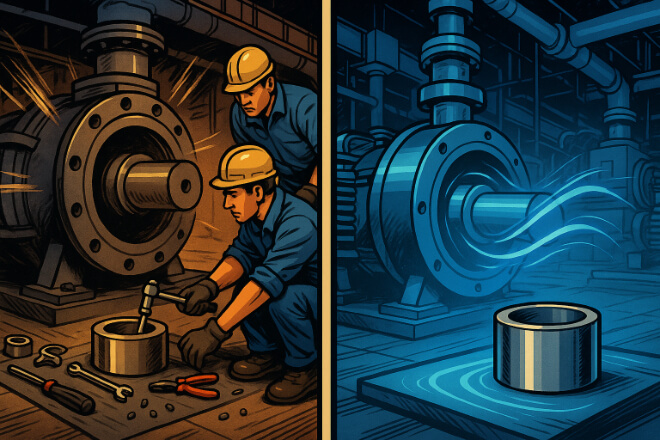

Maintenance cost is often the biggest hidden expense for equipment using conventional bushings.

1). For conventional bushings:

Wear fast

Cause shaft scratches

Require frequent replacement

Increase pump vibration

Can cause unexpected shutdown

2). For tungsten carbide bushings:

Long wear life

Stable performance in harsh fluids

Lower lubrication demand

Less shaft wear

Longer service interval

OEMs often discover that the higher purchase price of carbide bushings is small compared to the downtime reduction they achieve.

Replacement Frequency and Long-Term Value

Tungsten carbide bushings can last 3–10 times longer depending on working conditions.

Replacement frequency example (typical range)

| 素材の種類 | Average Lifetime | 注記 |

|---|---|---|

| ブロンズ | 6–12 months | High wear in pumps |

| ステンレス鋼 | 12–24 months | Better, but still wear issues |

| タングステンカーバイド | 3–10+ years | Much longer life |

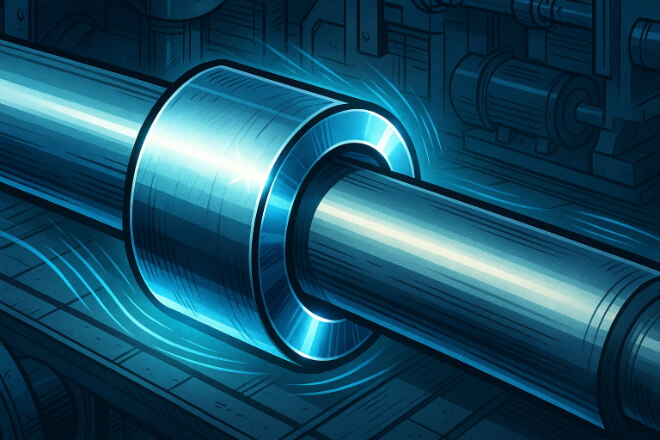

Energy Efficiency and Performance Stability

Worn bushings cause friction. Friction increases energy use.

Benefits of tungsten carbide for energy savings

Lower friction coefficient

Smoother surface finish (Ra ≤ 0.2 µm)

Less shaft drag

More stable shaft rotation

Reduced heat build-up

Over years of operation, these improvements can create meaningful energy savings.

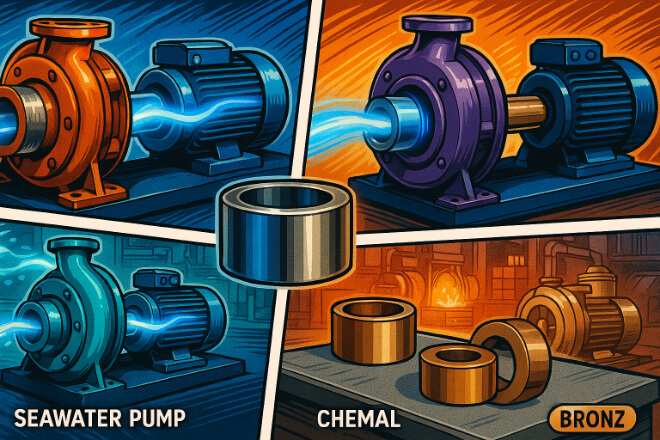

Application Suitability: Where Each Type Makes Sense

While tungsten carbide has many advantages, there are still cases where conventional bushings work well.

1). Tungsten carbide is best for:

High-speed pumps

Deepwell pumps

Chemical and seawater systems

Abrasive fluids (sand, slurry)

High load or high-pressure machines

2). Conventional bushings are suitable for:

Low-speed equipment

Non-abrasive fluids

Cost-sensitive temporary equipment

Applications with low running hours

Choosing the right type depends on your operational priorities—performance, lifetime, cost, or risk control.

結論

Although tungsten carbide bushings cost more upfront, they often reduce total cost over the full equipment life cycle.

Lower replacement frequency, fewer shutdowns, better wear resistance, and improved performance make carbide the best long-term investment for many OEMs and industrial users.

For mission-critical rotating equipment, tungsten carbide generally delivers the lowest total cost over time.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。