タングステンカーバイドブッシング are hard, heavy, and brittle. Even though they offer excellent 耐摩耗性, they can still chip, crack, or deform during transport if the packaging is not correct.

This guide explains the best practices for packaging and shipping tungsten carbide bushings so OEMs and industrial users can reduce damage, protect quality, and ensure safe delivery.

Why Proper Packaging Matters

Tungsten carbide has very high 硬度 but low flexibility. This combination means it can break if it receives sudden impact during transport. Proper packaging prevents:

Cracking or chipping

Surface scratches

Out-of-round distortion

Corrosion from moisture

Vibration damage during long-distance shipping

For OEMs, damaged bushings lead to delays, production downtime, and extra cost. Strong packaging reduces risk and protects your investment.

Understand the Main Risks During Shipping

Before choosing packaging, it is important to understand what type of damage can happen during shipping.

1). Key risks include:

Mechanical impact from drops or stacking

Vibration during long-distance trucking

Moisture exposure during sea shipping

Abrasion from metal-to-metal contact

Temperature shock in extreme climates

Poor handling by logistics personnel

2). Common Risk Table

| Risk | Cause | Possible Damage |

|---|---|---|

| Impact | Drops or heavy loads | Cracks or chipping |

| Vibration | Long-distance shipping | Surface wear, micro-cracks |

| Moisture | Sea freight humidity | Corrosion of binder phase |

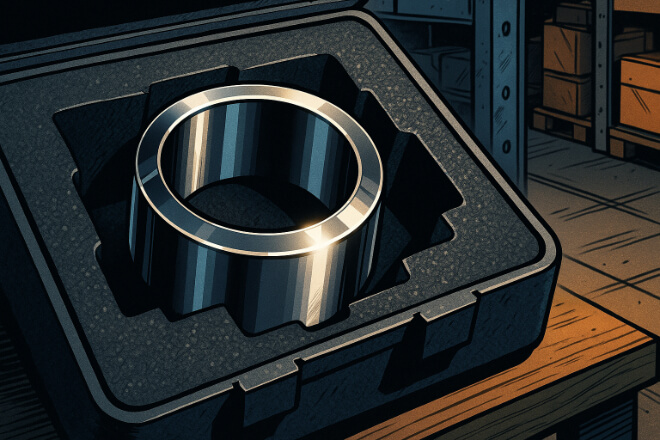

Best Practices for Individual Bushing Protection

Each bushing should be packaged in a way that prevents movement and damage.

1). Recommended methods

Use foam inserts to secure each bushing

Add plastic end caps to protect sharp edges

Wrap each bushing in anti-scratch film

Use anti-corrosion oil or VCI paper for humid regions

Keep bushings separated – never allow metal-to-metal contact

2). Ideal individual packaging

PE bag + foam slot + reinforced compartment

For large bushings: Custom-cut EVA foam

Proper individual packing is the first barrier against damage.

Choosing the Right Box and Cushioning Materials

The outer packaging must handle stacking, long trips, and high weight.

1). Recommended outer boxes

Double-layer corrugated box for air freight

Triple-layer corrugated box or plywood case for sea freight

Shock-absorbing lining inside the box

Weight clearly marked outside

2). Cushioning suggestions

Foam boards

Bubble wrap

Molded EVA blocks

Expanded polyethylene (EPE) sheets

3). Packaging Material Comparison Table

| 材料 | Shock Absorption | Moisture Resistance | Suitable For |

|---|---|---|---|

| EVA Foam | 素晴らしい | 良い | Heavy bushings |

| Bubble Wrap | 適度 | 適度 | Light parts |

| EPE Sheet | 良い | 良い | General packaging |

Palletizing and Container Loading

Proper palletizing ensures safety during truck and sea transport.

1). Best practices

Use fumigated wooden pallets

Arrange boxes by weight – heavier at the bottom

Add straps and stretch film to secure the load

Leave no empty gaps to avoid shifting

Use moisture-proof liners inside the container

2). For sea freight

Place desiccant bags inside pallets

Use waterproof covers

Avoid placing pallets near container doors

Pallet stability is key to preventing falls or collapse.

Documentation and Labeling for Smooth Shipping

Incorrect paperwork can delay customs clearance and increase cost.

1). What to include

Packing list

Commercial invoice

HS code (820900)

Export declaration

Material safety information (if required)

Weight and dimension sheet

Handling instructions

2). Labeling requirements

Fragile symbol

Upward direction arrows

Weight label

Pallet ID number

Bushing batch number

Good labeling improves handling safety and reduces mistakes.

Best Shipping Methods for Tungsten Carbide Bushings

Different logistics options offer different levels of protection and speed.

1). Air Freight

もっと早く

Higher cost

Lower moisture risk

Suitable for urgent orders

2). Sea Freight

More economical

Higher humidity

Longer delivery time

Must add moisture protection

3). Express Courier

Best for small quantities

Safe and fast

Higher per-kg price

4). Shipping Method Comparison Table

| Method | Speed | 料金 | リスクレベル |

|---|---|---|---|

| Air Freight | 速い | 高い | 低い |

| Sea Freight | 遅い | 低い | 中くらい |

| Express Courier | Very Fast | 中くらい | 低い |

結論

Proper packaging and shipping are essential to protect tungsten carbide bushings from impact, corrosion, and vibration.

By using strong packaging materials, correct palletizing, and the right shipping method, OEMs can greatly reduce damage and ensure safe delivery of every order.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。