Tungsten carbide (WC) bushings are known for their exceptional 硬度 そして 耐摩耗性, making them ideal for heavy-duty applications.

However, what truly sets WC bushings apart is their density, toughness, and impact resistance.

These three key properties make WC bushings suitable for demanding environments where wear, shock, and pressure are constant challenges.

This article explores why these characteristics make WC bushings stand out and how they contribute to the overall performance of industrial systems.

What Are WC Bushings?

WC bushings are made from tungsten carbide, a material known for its superior hardness and wear resistance.

Tungsten carbide is formed by combining tungsten (a heavy, dense metal) with carbon, creating a material that is incredibly hard and resistant to wear.

Key Features of WC Bushings:

高い 硬度: Tungsten carbide is one of the hardest materials known, making it ideal for applications that involve friction or abrasive wear.

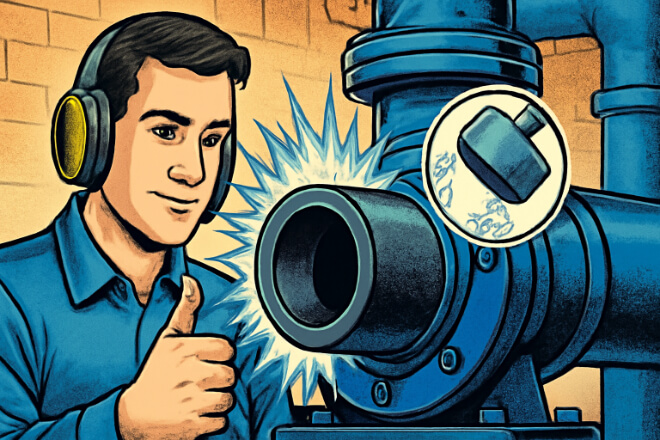

耐摩耗性: WC bushings perform excellently in abrasive environments, which is why they are commonly used in pumps, bearings, and other mechanical systems.

強靭さ: While extremely hard, WC is also designed to be tough, allowing it to resist cracking or breaking under mechanical stress.

Despite being a hard and durable material, the properties of 密度, toughness.

And impact resistance make WC bushings stand out in comparison to other materials, especially in high-stress environments.

Density of WC Bushings: Why It Matters

Density refers to how much mass a material has per unit volume. Tungsten carbide is extremely dense compared to other materials, which gives WC bushings several distinct advantages.

1). How Density Affects WC Bushings:

Increased 耐摩耗性:

The high 密度 of WC bushings allows them to resist wear more effectively. Denser materials tend to have fewer voids, which helps them maintain their integrity under friction.

- Reduced deformation:

A dense material is less likely to deform under pressure, which helps maintain the dimensional stability of the bushing, even in heavy-duty applications.

強度の向上:

WC bushings with high density are stronger and less prone to cracking or breaking, making them suitable for demanding environments such as 採掘, slurry handling, or high-pressure pumps.

2). Applications Benefiting from Density:

Slurry pumps: WC bushings with high density are ideal for pumps handling abrasive materials.

Heavy machinery: In applications with high load-bearing requirements, dense WC bushings ensure better structural stability and wear resistance.

Toughness: The Balance Between Hardness and Durability

Toughness is the ability of a material to absorb energy and deform without breaking.

While hardness refers to how resistant a material is to indentation or scratching, toughness refers to its ability to withstand impact or sudden stress.

1). 強靭さ of WC Bushings:

Improved resistance to mechanical stress: WC bushings are designed to be tough, meaning they can handle sudden impacts, vibrations, and shock loading without cracking or failing.

Prevention of brittle failure: One of the challenges with hard materials is their brittleness. Tungsten carbide’s toughness helps it resist cracking, making it ideal for applications with high mechanical stress.

Longer service life: The toughness of WC bushings ensures that they remain operational for longer periods, even in systems that are subjected to regular impacts and stress.

2). Applications Benefiting from Toughness:

鉱業: WC bushings are used in mining equipment, where they are exposed to high-impact forces and abrasive materials.

High-speed machinery: In machinery where vibrations and shock loading are common, the toughness of WC bushings prevents damage and ensures long-term performance.

Impact Resistance: Protecting Against Sudden Forces

Impact resistance refers to a material’s ability to absorb sudden energy from impacts without cracking or breaking.

This property is especially important in industries that deal with heavy machinery or high-speed operations.

1). Impact Resistance of WC Bushings:

Protection from mechanical shock: WC bushings are known for their ability to resist impact and shock loading, ensuring that they remain intact even under harsh operating conditions.

Prevention of wear from dynamic loading: In systems subject to frequent changes in load, such as rotating equipment or machinery, the impact resistance of WC bushings helps minimize wear and prolong their service life.

Maintaining performance in high-stress environments: The high impact resistance ensures that the bushing can continue to function in high-stress situations, reducing the risk of failure.

2). Applications Benefiting from Impact Resistance:

Centrifugal pumps: In pumps handling abrasive or slurry-type materials, impact resistance ensures that the bushing can withstand high-pressure impacts.

Compressors: WC bushings in compressors are exposed to dynamic loading, where impact resistance helps maintain performance over time.

How WC Bushings Perform in Abrasive Environments

WC bushings are highly effective in environments where abrasives are present.

Whether it’s handling slurries, cement, or sand, the combined 密度, 強靭さ, and impact resistance of WC bushings ensure they perform well in harsh conditions.

1). Key Benefits in Abrasive Environments:

Longer service life: The combination of high density and wear resistance ensures that WC bushings last longer in abrasive environments.

Reduced downtime: The impact resistance and toughness of WC bushings minimize the need for frequent maintenance or replacements, reducing downtime.

Improved efficiency: By maintaining their integrity under heavy wear and impact, WC bushings contribute to the overall efficiency of machinery and equipment.

2). Common Industries Using WC Bushings:

Mining and slurry handling: WC bushings are perfect for equipment exposed to abrasive slurries and high impact.

石油とガス: In industries where high temperatures and mechanical stress are common, WC bushings provide the durability needed to withstand extreme conditions.

結論

WC bushings are highly valued for their density, toughness, and impact resistance—properties that make them perfect for high-performance applications.

These characteristics ensure excellent wear resistance, improved durability, and better performance in harsh environments.

By understanding these benefits, companies can make informed decisions and enhance the longevity and efficiency of their systems with WC bushings.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。