In industries that rely heavily on tools like tungsten carbide tips for drilling, cutting, and grinding, managing costs effectively is crucial.

One approach many businesses consider to reduce costs is bulk ordering of tungsten carbide tips.

While ordering in bulk can seem like an economical option, it’s important to evaluate whether it truly leads to savings.

This blog will explore the advantages and potential drawbacks of bulk ordering tungsten carbide tips, helping decision-makers assess if this approach aligns with their business goals.

Understanding Tungsten Carbide Tips and Their Use

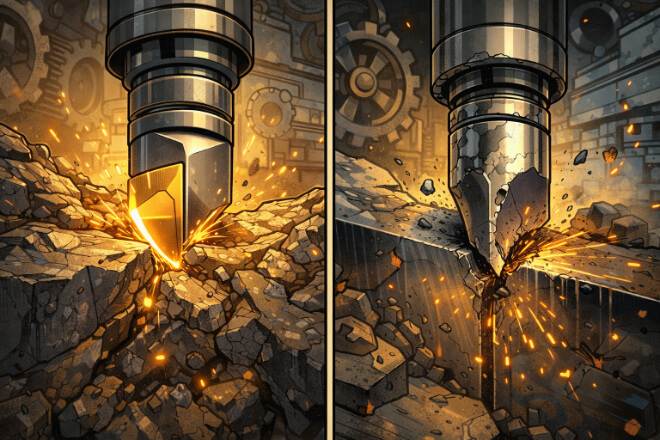

Tungsten carbide tips are essential tools in industries such as 採掘, construction, and manufacturing.

Known for their 硬度, 耐摩耗性, and durability, these tips are used in a wide range of high-performance applications.

Tungsten carbide’s unique properties make it ideal for cutting through tough materials like metal, concrete, and rock, and it can withstand extreme heat and abrasive environments.

Given the critical role these tips play in production, it’s vital to make cost-effective purchasing decisions.

But does buying in bulk actually help businesses save money in the long run? Let’s examine the factors that influence whether bulk ordering is more economical.

Benefits of Bulk Ordering Tungsten Carbide Tips

When evaluating whether bulk ordering tungsten carbide tips is worth the investment, businesses should first consider the benefits that this approach can offer.

1). Cost Savings Per Unit

One of the primary advantages of bulk ordering is the reduction in the unit price of each tip. Suppliers often offer discounts for large orders, lowering the overall cost per unit.

These savings can be significant, especially if your business uses a high volume of tungsten carbide tips.

Volume Discounts: Suppliers usually offer better pricing for bulk orders due to economies of scale. By purchasing in larger quantities, businesses can take advantage of these discounts, which can lead to considerable savings over time.

Lower Shipping Costs: Ordering larger quantities in a single shipment can reduce the cost of shipping per unit. This can help offset the higher upfront cost of purchasing in bulk.

2). Improved Stock Availability

Bulk ordering ensures that your business maintains a steady supply of tungsten carbide tips, which can help avoid shortages or delays in production.

Having enough stock on hand reduces the risk of running out of tools and allows operations to continue smoothly.

Consistent Supply: By ordering in bulk, businesses can ensure they have a reliable source of tungsten carbide tips available for uninterrupted production.

Less Risk of Price Fluctuations: Tungsten carbide prices can fluctuate based on market conditions, such as the price of raw materials like tungsten and cobalt. Ordering in bulk locks in prices, helping businesses avoid sudden increases in material costs.

3). Reduced Administrative Effort

Bulk ordering reduces the frequency of placing orders, saving time and administrative effort.

For businesses that use large quantities of tungsten carbide tips, managing frequent smaller orders can become time-consuming. With bulk ordering, the procurement process is simplified.

Less Frequent Ordering: By purchasing larger quantities, businesses can reduce the number of orders they need to place, leading to savings in administrative time.

Streamlined Inventory Management: With a larger stock of tungsten carbide tips, businesses can streamline inventory management, reducing the need for constant reordering.

Potential Drawbacks of Bulk Ordering Tungsten Carbide Tips

While bulk ordering can provide significant benefits, it’s also important to consider the potential drawbacks.

1). Upfront Investment

The most obvious downside of bulk ordering is the need for a larger upfront investment.

Purchasing large quantities of tungsten carbide tips requires a significant amount of capital, which may not always be feasible for smaller businesses or those with tight cash flow.

Cash Flow Impact: For some companies, the large upfront cost of bulk ordering may strain cash flow, especially if the tips are not needed immediately.

Storage Costs: Storing bulk orders requires space, and depending on the size of the order, this could lead to increased storage costs. Businesses will need to ensure they have adequate storage facilities to accommodate the bulk order.

2). Risk of Overstocking

When purchasing in bulk, there’s a risk of overstocking, especially if demand for tungsten carbide tips fluctuates.

If the tips aren’t used as quickly as expected, businesses could be left with excess stock that may become obsolete or take up valuable storage space.

Overstocking Risk: If demand drops or production slows down, businesses may end up with surplus stock that may not be needed for months or even years.

- Wasted Resources: Storing excess inventory may lead to wasted resources, especially if there’s a change in the tools required or a shift in production needs.

3). Technological Advancements

Tungsten carbide tips may experience improvements in quality, design, or manufacturing techniques over time.

If a company buys a large quantity of tips upfront, they may miss out on newer, more efficient tools that could improve performance or reduce costs in the future.

Advancements in Tool Design: If new, more advanced tungsten carbide tips are developed, businesses that bulk-ordered older models may be left with outdated inventory.

Obsolescence: As manufacturing technologies evolve, older batches of tungsten carbide tips may become less effective or less competitive, leading to a potential waste of resources.

How to Determine If Bulk Ordering is Right for Your Business

To determine if bulk ordering tungsten carbide tips is the best approach, businesses should consider the following factors:

Volume of Usage:

If your business uses a high volume of tungsten carbide tips, bulk ordering is likely a good choice.

For businesses with a lower demand, purchasing in smaller quantities may be more cost-effective.

Budget and Cash Flow:

Consider the financial situation of your business.

If you have sufficient funds and can manage the upfront investment, bulk ordering can provide savings.

However, if cash flow is tight, it may be better to purchase smaller quantities as needed.

Storage Capacity:

Ensure that your business has enough space to store bulk orders without incurring additional costs or risks.

Supply Chain Stability:

If you’re confident in the stability of your suppliers and the price of tungsten carbide, bulk ordering can help lock in favorable prices and ensure a steady supply.

結論

Bulk ordering tungsten carbide tips can be a cost-effective strategy for businesses that use a high volume of tools.

The benefits of volume discounts, improved stock availability, and reduced administrative effort make bulk orders attractive for many companies.

However, it’s important to carefully weigh the upfront investment, the risk of overstocking, and the potential for technological advancements before committing to a bulk order.

By considering these factors, decision-makers can determine if bulk ordering is the most economical choice for their business.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。