Asphalt milling is one of the most demanding operations in road construction and maintenance.

Milling teeth work under constant impact, abrasion, and heat while cutting through asphalt mixed with aggregates and sometimes concrete.

Tungsten carbide tips play a critical role in the performance and life of asphalt milling teeth.

Choosing the right carbide tip and maintaining proper wear balance can greatly improve milling efficiency and reduce operating costs.

This article explains how タングステンカーバイドチップ are used in asphalt milling teeth, how to select them correctly, and how to manage wear balance for better results.

1. Understanding Asphalt Milling Teeth and Working Conditions

Asphalt milling teeth are mounted on rotating drums and are responsible for breaking and removing road surfaces.

These teeth face extreme working conditions every minute they operate.

Key challenges include:

High impact loads from aggregates

Severe abrasion from sand and stone

Continuous heat generation

Dust and debris exposure

Because of these conditions, standard steel tips wear out very quickly.

Tungsten carbide tips are used to protect the cutting edge and extend tooth life under these harsh conditions.

2. Why Tungsten Carbide Tips Are Essential for Asphalt Milling

Tungsten carbide is chosen for asphalt milling teeth because it combines hardness with wear resistance. This balance is critical in road milling applications.

Main reasons carbide tips are used:

高い 硬度 resists abrasive aggregates

強い 耐摩耗性 extends service life

Stable cutting edge under impact

Reduced risk of rapid rounding

Without tungsten carbide tips, milling teeth would lose cutting ability quickly, increasing fuel use and reducing milling quality.

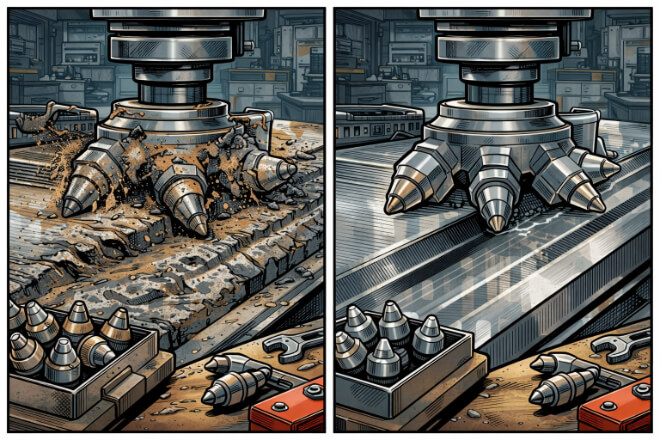

3. Types of Tungsten Carbide Tips Used in Milling Teeth

Not all tungsten carbide tips are the same. Different designs are used depending on milling depth, asphalt hardness, and machine type.

Common carbide tip types include:

Standard cylindrical tips for general asphalt milling

Conical tips for better self-rotation and wear distribution

Reinforced tips for heavy-duty or concrete-mixed asphalt

Choosing the correct tip shape helps improve cutting efficiency and supports balanced wear during operation.

4. Key Factors to Consider When Selecting Carbide Tips

Selecting the right tungsten carbide tip is not only about hardness. Several factors must be considered to match real job conditions.

Important selection factors:

Aggregate 硬度 and size

Milling depth and cutting speed

Drum rotation speed

Expected service life

A tip that is too hard may crack under impact, while a tip that is too soft may wear too fast.

The goal is to find the right balance between hardness and 強靭さ。

5. Understanding Wear Mechanisms in Asphalt Milling

Wear in asphalt milling teeth happens in several ways. Understanding these wear modes helps improve selection and wear balance.

Main wear mechanisms include:

Abrasive wear from sand and stone

Impact wear from large aggregates

Thermal wear caused by friction heat

Uneven wear due to poor rotation

Tungsten carbide tips slow down all these wear processes, but proper design and selection are needed to get the best results.

6. Importance of Wear Balance and Self-Rotation

Wear balance means the carbide tip wears evenly instead of forming flat spots or sharp edges.

Balanced wear extends tooth life and keeps cutting performance stable.

Wear balance is improved by:

Proper tip geometry

Smooth contact surfaces

Free rotation of the milling tooth

When tips rotate freely, wear is distributed evenly around the carbide surface. This prevents early failure and reduces replacement frequency.

7. Role of Tip Geometry in Wear Balance

Tip geometry strongly affects how wear develops during milling.

Good geometry design:

Promotes self-rotation

Reduces localized stress

Prevents edge chipping

Poor geometry can cause:

Flat wear areas

振動の増加

Faster tooth failure

Well-designed tungsten carbide tips help maintain smooth milling and stable machine operation.

8. Comparison of Carbide Tip Selection for Different Conditions

The table below shows how different carbide tip choices affect performance in various asphalt milling conditions.

| Milling Condition | Carbide Tip Requirement | Expected Performance |

|---|---|---|

| Soft asphalt | Standard hardness carbide | Good wear life, smooth cutting |

| Hard asphalt with stone | High wear-resistant carbide | Longer service life |

| Deep milling | Tough carbide with impact resistance | Reduced breakage |

| Mixed asphalt and concrete | Reinforced carbide tips | Stable cutting, balanced wear |

This comparison highlights why proper carbide selection is critical for different job sites.

9. Maintenance Practices to Support Wear Balance

Even the best タングステンカーバイドチップ need proper maintenance to perform well.

Good maintenance practices include:

Regular inspection of tooth rotation

Cleaning debris from holders

Replacing worn holders on time

Using proper installation torque

These steps help ensure carbide tips rotate freely and wear evenly, maximizing their service life.

10. Cost Benefits of Correct Selection and Wear Balance

Correct carbide tip selection and good wear balance directly reduce operating costs.

Key cost advantages include:

Longer tooth life

Fewer machine stoppages

Lower fuel consumption

More consistent milling quality

For decision-makers, investing in the right tungsten carbide tips pays off through lower total cost per ton milled.

結論

Tungsten carbide tips are a core component of asphalt milling teeth performance.

By selecting the right tip type, matching hardness and toughness to job conditions, and maintaining proper wear balance, milling operations can achieve longer tool life and better cutting results.

Understanding how wear develops and how tip geometry supports balanced wear helps decision-makers reduce costs and improve productivity.

For asphalt milling, the right carbide tip strategy is not optional—it is essential.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。