導入

精密機械加工・製造の世界では、工具の性能が生産品質、効率、そしてコストに直接影響を及ぼします。炭化タングステン切削工具は、その卓越した硬度、耐摩耗性、そして高速・高温条件下でも切れ味を維持する能力により、業界標準となっています。

CNC 加工、金型製造、または大型工業用切削のいずれの場合でも、炭化タングステン切削工具を理解することで、情報に基づいた意思決定を行い、業務を最適化できるようになります。

この総合的な初心者向けガイドでは、タングステンカーバイド切削工具とは何か、その利点、製造方法、利用可能な種類、パフォーマンスを最大限に高めるための実用的な使用上のヒントについて説明します。

炭化タングステン切削工具とは何ですか?

タングステンカーバイド切削工具は、タングステンカーバイド(WC)粒子を金属結合剤(通常はコバルトまたはニッケル)で結合させた複合材料から製造される工具です。タングステンカーバイド自体は非常に硬い材料で、モース硬度は8.5~9程度と、従来の高速度鋼(HSS)よりも大幅に高い硬度を誇ります。

炭化タングステン切削工具のユニークな特性により、鋭い切れ味を長期間維持でき、高温でも摩耗や変形に耐え、硬化鋼、ステンレス鋼、鋳鉄、複合材、さらには一部のセラミックなど、さまざまな加工困難な材料を正確に切削できます。

炭化タングステン切削工具の主な利点

ワークショップでタングステンカーバイド切削工具を使用する主な利点は次のとおりです。

✅ 優れた硬度と耐摩耗性

タングステンは HSS 工具よりもはるかに高い硬度を備えているため、より硬い材料を切断しながらも、切れ味を長時間維持することができます。

✅ 高い耐熱性

炭化タングステン工具は硬度を失うことなく高い切削温度に耐えることができるため、高速加工に適しています。

✅ ツール寿命の延長

摩耗が減るため、ツールの交換回数が少なくなり、ダウンタイムが短縮され、生産性が向上します。

✅ 優れた寸法精度

タングステンカーバイド切削工具は、厳しい公差と高品質の表面仕上げを実現し、後処理の必要性を軽減するのに役立ちます。

✅ 多様な素材に対応

これらは、鉄金属、非鉄金属、複合材料、さらには一部の非金属材料の切断に効果的であり、操作の柔軟性が向上します。

✅ 生産性の向上

タングステンカーバイド工具を使用すると、より高い切削速度と送りが可能になり、加工サイクル時間が短縮され、スループットが向上します。

炭化タングステン切削工具はどのように製造されるのでしょうか?

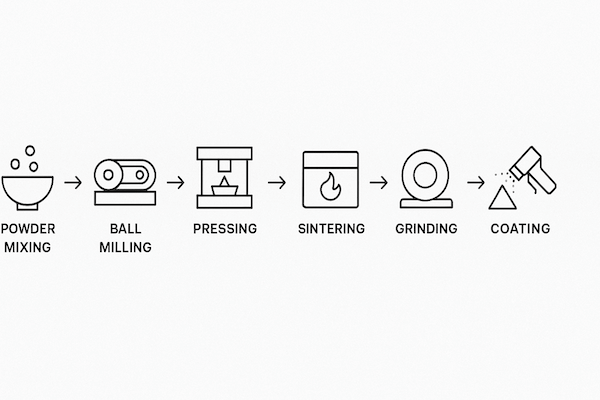

炭化タングステン切削工具の製造には、いくつかの正確な手順が必要です。

1️⃣ 粉末混合

炭化タングステン粉末は、金属結合剤(通常はコバルトまたはニッケル)と混合され、場合によっては少量の粒成長抑制剤(炭化バナジウムなど)と混合されます。

2️⃣ ボールミル

混合物を液体とともにボールミル粉砕して均質なスラリーを作成し、炭化物粒子とバインダーの均一な分散を確保します。

3️⃣ スプレー乾燥

スラリーを噴霧乾燥して、プレスに適した球状顆粒を形成します。

4️⃣ 押す

顆粒は、一軸圧縮または等方圧縮を使用して所望の形状に圧縮されます。

5️⃣ 焼結

グリーン成形体は、制御された雰囲気下で高温(約 1350 ~ 1500°C)で焼結され、炭化物粒子がバインダー相と結合してほぼ完全な密度を実現します。

6️⃣ 成形と研磨

焼結後、ツールはダイヤモンドホイールを使用して正確な寸法に研磨され、厳しい公差が達成されます。

7️⃣ コーティング(オプション)

多くの超硬切削工具には、硬度の向上、摩擦の低減、動作中の工具寿命の延長を目的として、TiAlN、AlTiN、DLC などのコーティングが施されています。

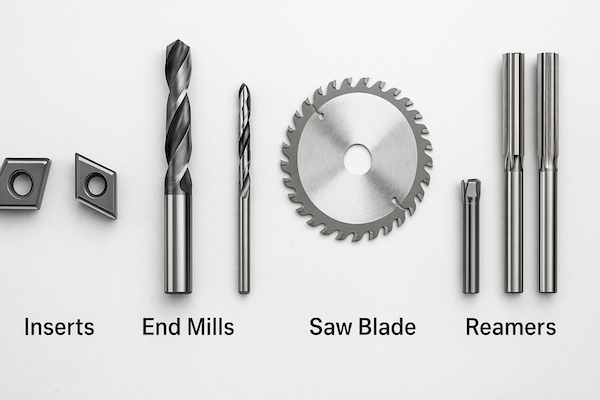

炭化タングステン切削工具の種類

炭化タングステン切削工具は、さまざまな加工作業に対応するためにさまざまな形で提供されています。

🔹 超硬インサート

旋削、フライス加工、ボーリング加工で使用される交換可能なチップ。さまざまな形状(四角、三角形、丸)と形状があり、特定の切削ニーズに対応します。

🔹 超硬エンドミル

CNC 加工および金型加工における高速フライス加工、輪郭加工、スロット加工操作に使用されます。

🔹 超硬ドリルビット

高い精度と真直度を維持しながら、硬い材料に精密に穴あけするのに最適です。

🔹 超硬鋸刃

金属、複合材、一部の非鉄金属をきれいで正確な切断に使用します。

🔹 超硬リーマとタップ

精度が重要な穴仕上げおよびねじ切りアプリケーションに使用されます。

🔹 カスタムカーバイドツール

独自の切断ソリューションを必要とする特定の産業用途向けにカスタマイズされた形状とコーティング。

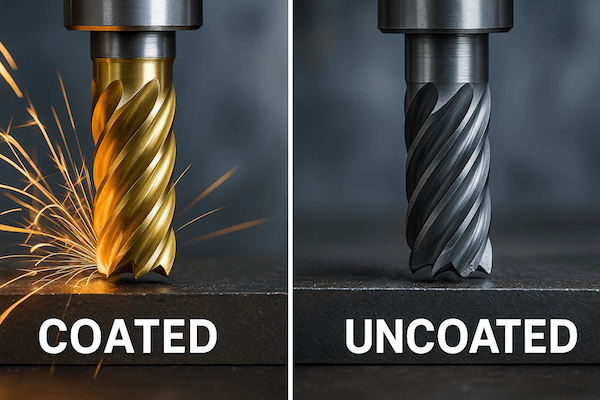

コーティング付き炭化タングステン切削工具とコーティングなし炭化タングステン切削工具

コーティングされていない超硬工具 多くの一般的な機械加工に適しており、優れた靭性を備えていることが多い。しかし、 コーティングされた超硬工具 (TiAlN、AlTiN、TiCN、または DLC 付き) は次の機能を提供します:

✅ 耐摩耗性の向上

✅ より高い切断速度

✅ 摩擦と発熱の低減

✅ 工具寿命の延長

コーティングされた工具は、高速加工、ドライ加工、研磨材や硬化材の加工に特に効果的です。

炭化タングステン切削工具を効果的に使用するためのヒント

タングステンカーバイド切削工具の性能と寿命を最大限に高めるには:

✅ 加工する材料と工具の形状に応じて適切な切削速度と送りを使用します。

✅ 熱とチップの除去を管理するために適切な冷却剤または潤滑剤を使用してください。

✅ ツールの欠けや破損を防ぐため、過度の振動を避けてください。

✅ 刃先が誤って損傷するのを防ぐため、ツールは清潔で乾燥した環境に保管してください。

✅ ツールを定期的に点検し、目立った摩耗により切削品質に影響が出ている場合は交換してください。

コストと価値: タングステンカーバイド工具への投資は価値があるか?

炭化タングステン切削工具は HSS 工具よりも初期コストが高くなりますが、長期的には次の理由により工具コストが大幅に削減されます。

✅ ツール寿命の延長

✅ より高い加工速度を実現

✅ ツール交換時のダウンタイムを削減

✅ 部品の品質向上と手直しの削減

これにより、生産性と製品品質の向上を目指すワークショップにとって、コスト効率の高い投資となります。

炭化タングステン切削工具に関するよくある質問

Q: 炭化タングステン切削工具は再研磨できますか?

A: はい、超硬切削工具はダイヤモンド研削ホイールを使用して再研磨することができ、使用寿命を延ばすことができます。

Q: ステンレス鋼の加工に適していますか?

A: はい、タングステンカーバイド工具は硬度と耐熱性があるため、ステンレス鋼やその他の加工が難しい材料の加工に最適です。

Q: 金属以外の素材にも使用できますか?

A: はい、超硬切削工具は適切なパラメータを使用して、特定の複合材料、プラスチック、さらにはセラミックを加工できます。

Q: 通常、どれくらい持続しますか?

A: 工具寿命は材料の硬度、切削パラメータ、工具の種類によって異なりますが、通常は同様の条件下では HSS 工具よりも 5 ~ 10 倍長持ちします。

Q: 炭化タングステン切削工具はリサイクルできますか?

A: はい、超硬工具はリサイクルして貴重なタングステンとコバルトを回収し、新しい工具に再利用することができます。

炭化タングステン切削工具で製造業者が効率を向上した方法

ステンレス鋼部品を専門とする精密機械加工工場が、HSSエンドミルをRetopのタングステンカーバイドエンドミルに交換しました。工場からは次のような報告がありました。

✅ ツール寿命の延長: ツールの寿命が6倍長くなりました。

✅ サイクルタイムの短縮: 40%により加工速度が上がり、生産時間が短縮されました。

✅ コスト削減: ツール交換によるダウンタイムが短縮され、月間生産性が 25% 増加しました。

✅ 表面品質: 部品の加工後の仕上げが少なくなり、全体的な生産コストが削減されました。

これは、要求の厳しい加工環境でタングステンカーバイド切削工具に切り替えることによる具体的な利点を示しています。

結論

タングステンカーバイド切削工具は、比類のない硬度、耐熱性、そして長寿命により、現代の機械加工に革命をもたらしました。その特性、種類、製造プロセス、そして効果的な使用方法を理解することで、メーカーは生産性を大幅に向上させ、運用コストを削減することができます。

機械加工工程のアップグレードをお考えなら、 タングステンカーバイド切削工具は、高精度で要求の厳しい環境でも一貫した結果をもたらす信頼性の高い投資です。

性能と耐久性を重視して設計された高品質のタングステンカーバイド切削工具については、 Retopのタングステンカーバイド切削工具 今日。