導入

CNC加工は現代の製造業において極めて重要な役割を果たしています。高精度、高速、そして均一な部品の製造に役立ちます。最良の結果を得るには、適切な切削工具を使用することが非常に重要です。

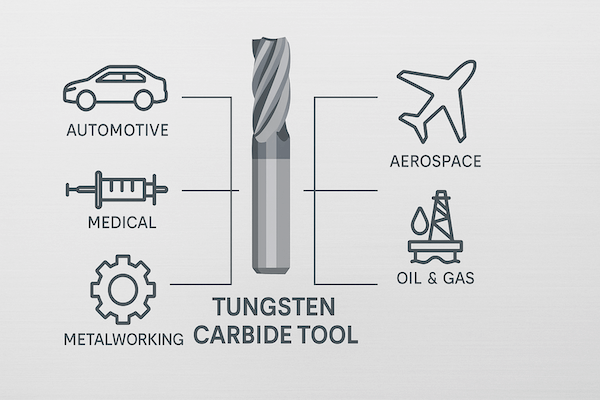

炭化タングステン切削工具 CNC加工では、多くの利点があるため、タングステンカーバイド切削工具が広く使用されています。強度が高く、長寿命で、高品質な部品の製造に役立ちます。このガイドでは、CNC加工でタングステンカーバイド切削工具を使用する主な利点を、簡潔かつ明確に説明します。

炭化タングステン切削工具とは何ですか?

タングステンカーバイド切削工具は、タングステンカーバイド粒子と金属結合剤(通常はコバルト)の混合物から作られています。タングステンカーバイドは鋼よりもはるかに硬いため、切削工具の鋭い刃先を長期間維持することができます。

これらの工具は、フライス加工、旋削加工、穴あけ加工、切削加工など、多くのCNC加工に使用できます。高速・高温環境にも対応できるため、製造業で広く使用されています。

炭化タングステン切削工具を使用する利点

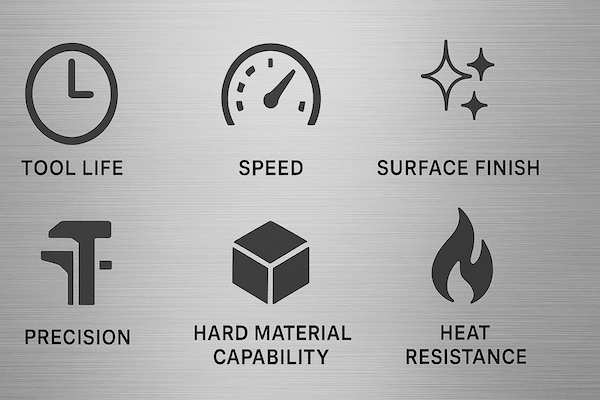

1️⃣ ツール寿命の延長

タングステンカーバイド工具は、高速度鋼(HSS)工具よりもはるかに長持ちします。硬い材料を切削しても摩耗が早くありません。そのため、工具を頻繁に交換する必要がなく、時間とコストを節約できます。

ツール交換回数を減らすことで、CNC 加工の生産性を向上させることができます。

2️⃣ 高速切断

これらのツールは、切削能力を損なうことなく、より高速に動作できます。切削速度が速いということは、生産時間が短縮されることを意味し、より短時間でより多くの部品を生産できます。

タングステンカーバイド工具を使用すると、生産性が向上し、作業場でのリードタイムが短縮されます。

3️⃣ 表面仕上げの向上

タングステンカーバイド工具は鋭い切れ刃を維持し、機械加工部品の表面仕上げを向上させます。良好な表面仕上げにより、研磨や研削などの追加仕上げ工程の必要性が軽減されます。

これにより、時間を節約し、生産コストを削減できます。

4️⃣ 高精度と正確性

CNC加工では、厳しい公差を維持することが重要です。タングステンカーバイド切削工具は摩耗が少なく、切削形状を長期間維持するため、この目標達成に役立ちます。

これは、高精度が求められる航空宇宙、医療、自動車などの業界にとって非常に役立ちます。

5️⃣ 硬い素材に適しています

炭化タングステン切削工具は、ステンレス鋼、チタン、鋳鉄などの硬質材料を容易に切断できます。そのため、硬質金属を扱う産業に適しています。

硬い材料を機械加工する必要がある場合は、タングステンカーバイド工具を使用すると効率的に加工できます。

6️⃣ 耐熱性

CNC加工では、切削加工中に大量の熱が発生します。タングステンカーバイド工具は、硬度や形状を損なうことなく高温に耐えることができます。

これにより、熱による工具の故障を心配することなく、高速加工に使用することができます。

7️⃣ 長期的には費用対効果が高い

タングステンカーバイド工具はHSS工具よりも初期コストが高い場合がありますが、長期的にはコスト削減につながります。工具寿命が長く、工具交換の回数が少ないためダウンタイムが短縮され、加工速度も向上します。

これらすべての利点により、部品あたりの全体的なコストを削減できます。

CNC加工における炭化タングステン切削工具の使用に関するヒント

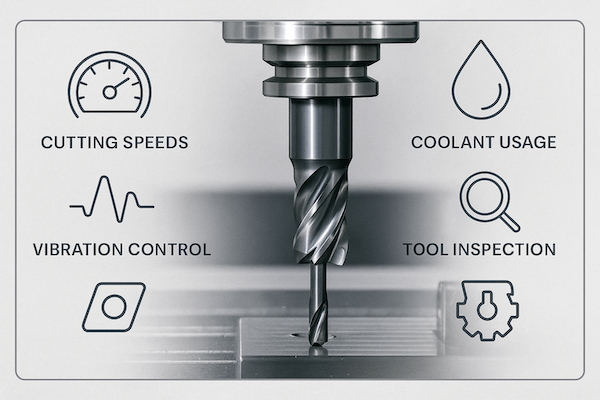

✅ 素材に適したツールを選択してください。

材料が異なれば、切削工具の形状とコーティングも異なります。

✅ 適切な切削速度と送りを使用してください。

ツールの損傷を避けるために、材料の推奨速度を確認してください。

✅ 必要に応じて冷却剤を使用してください。

クーラントは熱を減らし、工具寿命を延ばすのに役立ちます。

✅ ツールを定期的に点検してください。

タングステンカーバイド工具であっても、いずれは摩耗します。定期的な点検を行うことで、高品質な加工を維持できます。

✅ ツールを安全に保管してください。

損傷を防ぐために、ツールは清潔で乾燥した場所に保管してください。

炭化タングステン切削工具にRetopを選ぶ理由

Retopは、CNC加工用の高品質タングステンカーバイド切削工具を提供する信頼できるサプライヤーです。一貫した品質、高精度、長寿命の工具の製造に注力しています。当社の工具は、お客様の工場における生産性の向上、コスト削減、そして高品質な成果の実現に貢献します。

✅ タングステンカーバイド製造における 14 年以上の経験。

✅ ISO認証を受けた生産と品質管理。

✅ 加工ニーズに合わせたカスタム ソリューション。

✅ 迅速な対応と世界中への発送。

当社の製品の詳細については、 Retop公式サイト.

結論

CNC 加工でタングステンカーバイド切削工具を使用すると、次のような多くの利点があります。

✅ 工具寿命が延びる

✅ より速い切断速度

✅ 表面仕上げが向上

✅ 高精度と正確性

✅ 硬い材料を切断する能力

✅ 耐熱性

✅ 長期的にはコスト削減

これらの利点は、CNC加工の効率、生産性、そして品質の向上に役立ちます。加工能力を強化したいなら、タングステンカーバイド切削工具への投資は賢明な選択です。