はじめに:炭化タングステン工具におけるグレードの重要性

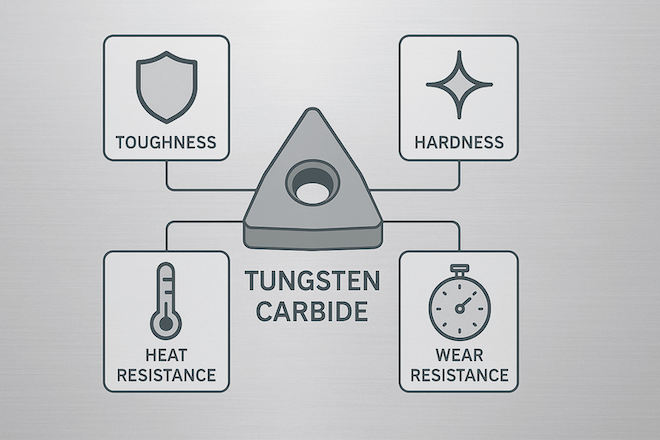

タングステンカーバイド切削工具を使用する際は、グレードを理解することが重要です。グレードは工具の硬度、靭性、そして最適な用途を定義します。このガイドは、タングステンカーバイドのグレードとは何か、なぜ重要なのか、そして適切なグレードを選ぶ方法を理解するのに役立ちます。

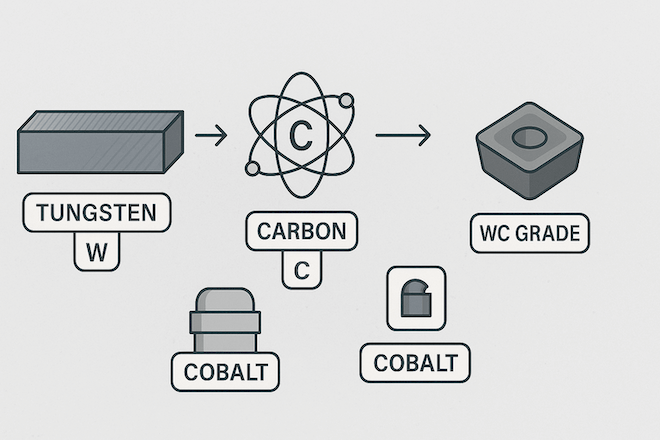

タングステンカーバイドのグレードとは何ですか?

あ タングステンカーバイドグレード WC粒子(炭化タングステン)と バインダーメタル (通常はコバルト)。これらの材料の比率とサイズによって、工具の強度と性能が決まります。例えば:

WCが高いほど硬度が増す

コバルトが多いほど靭性が高まる

グレードは、YG6、YG8、YG10X などのようにラベル付けされています。各グレードは、異なる用途向けに作られています。

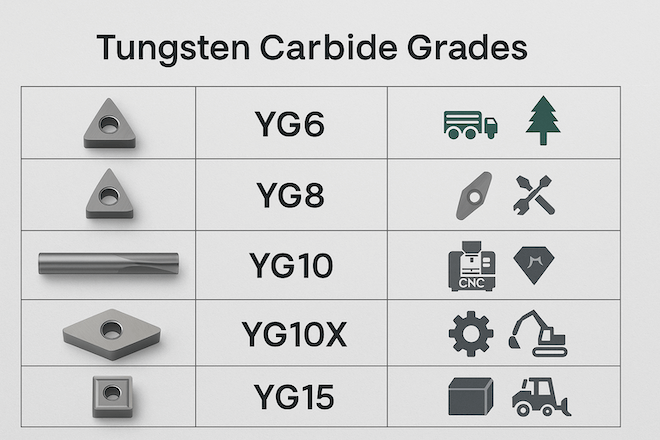

一般的な炭化タングステングレードとその用途

以下に、人気のあるグレードをいくつか簡単に紹介します。

| 学年 | 硬度(HRA) | 強靭さ | 応用 |

|---|---|---|---|

| YG6 | 90.5 | 中くらい | 一般切削、非鉄金属 |

| YG8 | 89.5 | 高い | 木工、軟鋼 |

| YG10 | 91.0 | 中高 | 鋼、鋳鉄 |

| YG10X | 92.0 | 中くらい | 精密加工、高耐摩耗 |

| YG15 | 89.0 | 非常に高い | 衝撃荷重、建設ツール |

適切なグレードの選び方

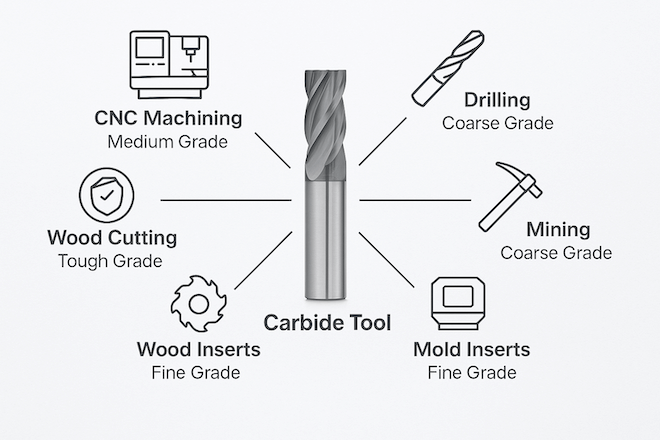

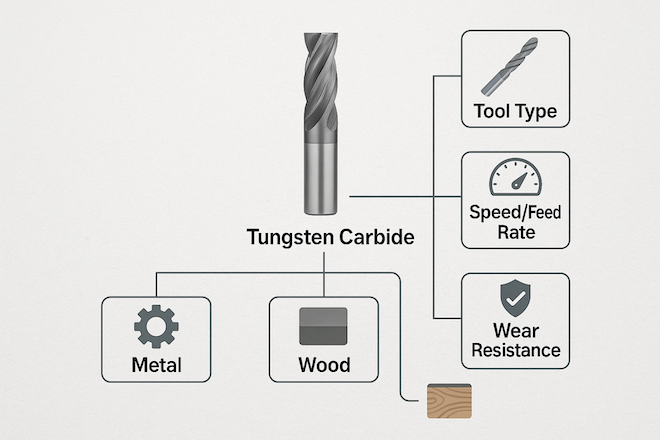

正しい選択 炭化物グレード 依存するもの:

被削材:鉄、アルミ、木材等

切削条件:速度、送り、温度

ツールタイプ: インサート、エンドミル、ドリルなど。

必要な仕上げ: 粗い表面か精密な表面か?

硬い鋼材を扱う場合は、YG10Xのような高硬度グレードをお選びください。鉱山などで衝撃荷重がかかる場合は、YG15のような高強度グレードをお選びください。

難しい成績と難しい成績

ハードグレード:

耐摩耗性の向上

高速切断に最適

連続的で安定したカットに最適

タフグレード:

欠けにくい

中断されたカットや荒いカットに最適

建設や採掘に役立つ

それぞれをいつ使用するかを知ることが、パフォーマンスとツール寿命の鍵となります。

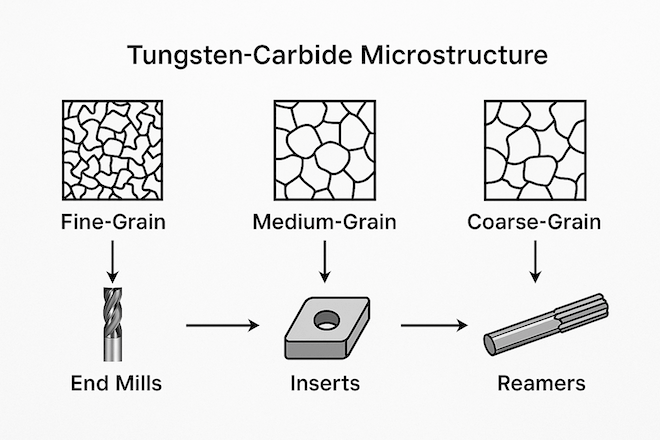

等級における粒度の重要性

コバルト%のほかに、 粒度 グレードにも影響します:

微粒子炭化物 = 優れた刃持ち

粗粒炭化物 = 優れた靭性

YG10Xのような細粒度は精密工具に最適です。粗粒度は高負荷工具に適しています。

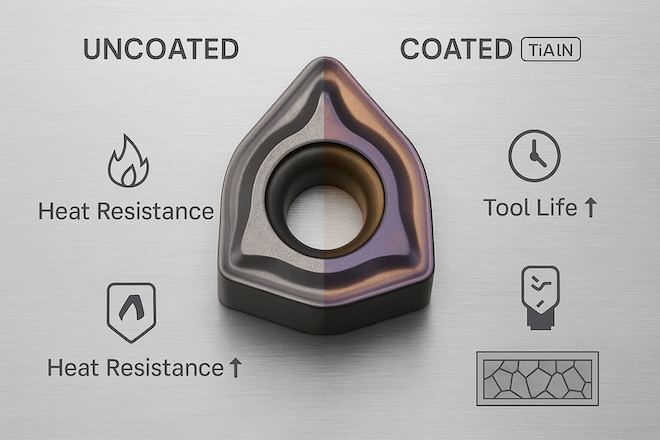

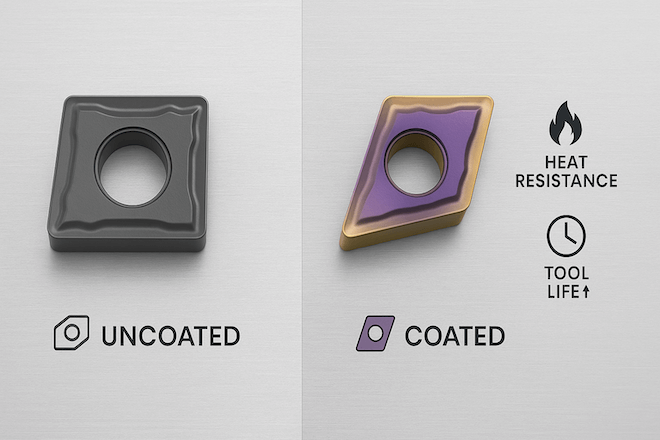

コーティング超硬工具のグレード

いくつかの タングステンカーバイド切削工具 TiAlN、TiCN、またはDLCコーティングが施されています。下地のグレードも重要です。コーティングによって以下の点が向上します。

耐熱性

潤滑

工具寿命

ただし、ベースとなる炭化物のグレードは、作業に適合している必要があります。