炭化タングステン切削工具 硬度と長い工具寿命でよく知られており、CNC加工でよく使用されます。 航空宇宙, 自動車、その他多くの高精度産業に使用されています。

しかし、これらの耐久性のあるツールであっても、適切に使用またはメンテナンスしないと問題が発生する可能性があります。

この記事では、タングステンカーバイド切削工具を使用する際に直面する最も一般的な問題を検討し、それぞれに対するシンプルで実用的な解決策を紹介します。

機械工、ショップオーナー、生産エンジニアのいずれであっても、これらの問題を理解することで、ツールの寿命を延ばし、コストのかかるダウンタイムを回避することができます。

1. 工具の早期摩耗

問題: タングステンカーバイドは高い 耐摩耗性送りや速度が不適切であったり、冷却剤の使用が不十分であったり、ワークピースの材質が低かったり、作業に適さないツールを選択したりすると、ツールが急速に摩耗してしまうことがあります。

解決:

送り速度と切削速度を 硬度 およびワークピース材料の靭性。

高品質のクーラントを使用し、切削刃に適切なクーラントが供給されるようにします。

用途に適した超硬合金グレードをお選びください。耐摩耗性に優れたグレードもあれば、靭性を向上させたグレードもあります。

表面保護と耐熱性を強化するために、TiAlN や DLC などの適切なコーティングを施します。

切断パラメータを監視し、予防保守スケジュールを確立します。

ツールの摩耗を監視し、パラメータを早期に調整することで、予期しないツールの故障を防ぐことができます。

2. エッジの欠けや破損

問題:超硬工具は非常に硬いものの、延性は低い。つまり、機械的衝撃、激しい振動、切削の中断、不適切な固定などにより、欠けたり破損したりする可能性があります。

解決:

振動を減らすために、ツールとワークピースの両方をしっかりと固定します。

応力集中を軽減するには、超硬インサートまたはチップブレーカー形状の工具を使用します。

機械とセットアップが負荷に対応できない場合は、硬い材料を深く切ることは避けてください。

アプリケーションに断続切削が含まれる場合は、より耐衝撃性の高い超硬グレードの使用を検討してください。

安定したスピンドルとスムーズな加速/減速を備えた CNC マシンを使用します。

3. ビルドアップエッジ(BUE)

問題: アルミニウムや銅などの延性材料や柔らかい材料を加工する場合、材料が工具の刃先に付着して構成刃先が形成されることがあります。

これにより、切断性能が低下し、部品の寸法が一定しなくなります。

解決:

研磨された超硬工具、または TiB2 や DLC などの固着防止コーティングが施された工具を使用してください。

接着時間を最小限に抑えるには、スピンドル速度を上げます。

チップの厚さが厚すぎる場合は、送り速度を下げてください。

摩擦と熱を減らすために、冷却剤または潤滑剤ミストを塗布します。

鈍くなった工具はすぐに交換するか研ぎ直してください。

4. 表面仕上げが悪い

問題: 摩耗した工具、不適切な速度や送りを使用した場合、または刃先が正しく研磨されていない場合、表面が荒れたり、裂けたり、傷ついたりすることがよくあります。

解決:

定期的にツールを点検し、鈍くなったツールは研ぐか交換してください。

より滑らかなカットを実現するには、送りを低くし、スピンドル速度を高くした仕上げパスを使用します。

高精度の用途にはマイクログレインカーバイド工具を使用します。

摩擦を減らし、よりきれいな切断を可能にするコーティングを選択してください。

振動やびびりを防ぐために切削工具のバランスを取ります。

5. 熱亀裂または熱損傷

問題:高速加工中に過剰な熱が発生すると、特に適切なクーラントがない場合、熱亀裂が発生する可能性があります。これにより刃先が弱くなり、工具の破損につながります。

解決:

切削領域に向けて連続的な冷却液の流れを使用します。

超合金または硬質金属を扱うときは、乾式加工を避けてください。

AlTiN や SiAlON などの高度なコーティングを施した耐熱炭化物グレードおよびツールを使用します。

過度の熱発生を避けるために最適な速度と送りを維持します。

連続的に加工する場合は、切削と切削の間に工具を冷却してください。

6. ツールが許容値を保持していない

問題: 時間の経過とともに、超硬工具は摩耗、工具のたわみ、またはセットアップの調整不良により、仕様外の部品を生産する場合があります。

解決:

強化されたボディを備えた精密研磨された超硬工具を使用します。

ツールホルダーとスピンドルが適切に調整されていることを確認してください。

摩耗したインサートや刃先を定期的に点検し、交換してください。

工具摩耗データに基づいて CNC プログラムを再調整します。

再現性の高い固定式またはモジュール式のツール システムの使用を検討してください。

7. 再研磨後の急速な工具破損

問題: 研ぎたての工具は、研削形状が不適切であったり、過熱したり、再調整中に微小な亀裂が生じたりして、すぐに故障することがあります。

解決:

超硬合金用に設計されたダイヤモンド研削ホイールのみを使用してください。

熱による損傷を防ぐために、必ずクーラントを使用して研磨してください。

元の工場の形状と角度に従います。

超硬工具の経験がある専門家に研磨を外注することを検討してください。

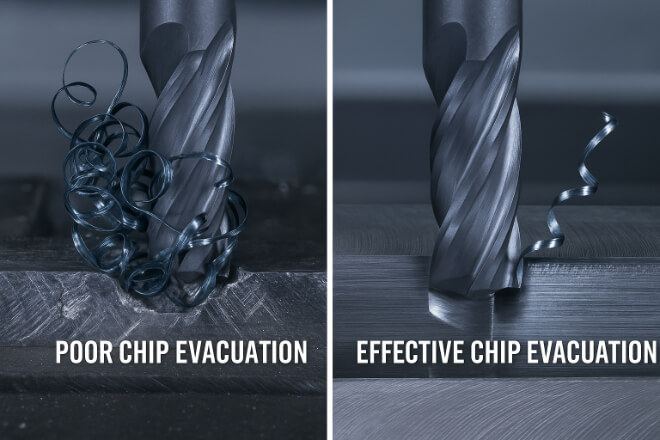

8. チップコントロールの問題

問題: 不適切なチップ排出は、チップの詰まり、傷、過熱、さらには工具の破損につながります。

解決:

最適化されたチップフルートまたはチップブレーカーを備えた超硬工具を使用します。

切削片を洗い流すために、冷却液の圧力と清潔さを維持します。

深穴加工の場合は、ペッキングサイクルまたはスルークーラントツールを使用します。

理想的なチップの形状とサイズを維持するために切削パラメータを調整します。

最後に

タングステンカーバイド切削工具は強度、信頼性、効率性に優れていますが、正しく使用した場合に限られます。問題の多くは、不適切な送り、冷却不良、メンテナンス不足などから発生します。

これらの一般的な問題を理解し、解決方法を知ることで、時間を節約し、コストを削減し、あらゆるツールを最大限に活用できるようになります。

適切なツールを選択する場合、再調整が必要な場合、または機械加工の問題のトラブルシューティングが必要な場合でも、 リトプズ は、専門家のアドバイスと質の高いソリューションであなたの仕事をサポートします。