炭化タングステン切削工具 are widely used in industries like aerospace, automotive, and general manufacturing.

They are known for their toughness, precision, and ability to cut hard materials. However, there are still many misunderstandings about how these tools work, how long they last, and how much they cost.

These myths often lead to poor purchasing decisions or missed opportunities for improving efficiency.

In this article, we’ll debunk the most common myths about tungsten carbide cutting tools. Whether you’re a shop floor supervisor, a purchasing manager, or a senior executive, this guide will help you make better choices and avoid common pitfalls.

Myth 1: Tungsten Carbide Tools Are Too Expensive

Reality: While tungsten carbide tools may cost more upfront compared to high-speed steel (HSS), they last much longer and deliver better performance.

This means fewer tool changes, less downtime, and better-quality parts. In the long run, they save money.

Carbide tools also allow for higher cutting speeds, which increases throughput. When used correctly, the return on investment (ROI) is clear.

Companies that measure total cost of ownership—not just purchase price—see carbide tools as a cost-effective choice.

Myth 2: Carbide Tools Are Only for Hard Materials

Reality: Yes, tungsten carbide excels at cutting hard materials like steel, cast iron, and titanium. But that doesn’t mean it can’t handle softer materials.

With the right tool geometry and coatings, carbide can also be used for cutting aluminum, plastic, and composites.

In fact, many shops use polished carbide tools or DLC-coated variants to machine aluminum without material sticking. It all comes down to choosing the right tool for the job.

Myth 3: All Carbide Tools Are the Same

Reality: This is a dangerous assumption. Carbide tools come in many grades and geometries.

Fine-grain carbide offers better 耐摩耗性, while coarse-grain carbide is more impact-resistant. Some tools are optimized for finishing, others for roughing.

Cutting edge design, flute shape, coating type, and tool balance also make a big difference. Using the wrong tool—even if it’s made of carbide—can result in faster wear, poor surface finish, or even tool breakage.

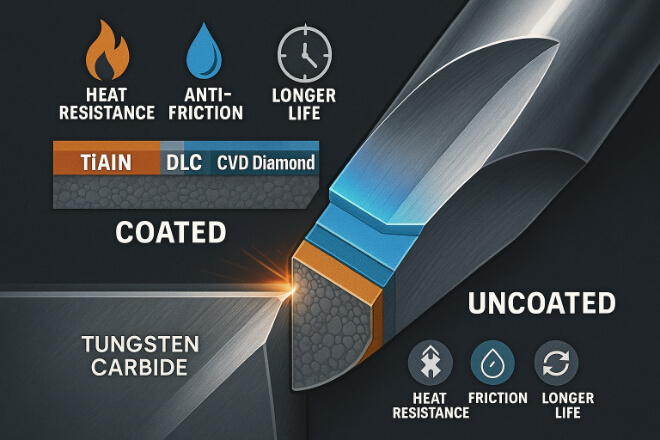

Myth 4: Coatings Are Just for Looks

Reality: Tool coatings are more than a pretty surface. They reduce heat, lower friction, and prevent materials from sticking to the cutting edge.

Popular coatings like TiAlN, DLC, or CVD diamond are designed for specific materials and use cases.

例えば:

TiAlN helps with heat resistance in dry cutting.

DLC prevents aluminum from welding onto the tool.

CVD diamond is perfect for cutting graphite and composites.

Skipping coatings can reduce tool life and quality.

Myth 5: Carbide Tools Don’t Need Maintenance

Reality: Even the strongest carbide tool wears over time. Ignoring wear leads to poor part quality, unexpected downtime, and even damage to machines.

Regular inspection, proper storage, and cleaning help extend tool life. Regrinding and recoating services also allow you to reuse high-value carbide tools instead of replacing them.

Well-maintained carbide tools perform better, last longer, and save costs in the long run.

Myth 6: Tool Wear Is Always Visible

Reality: Not all tool wear shows up as cracks or chips. Sometimes tools dull gradually or suffer from microscopic edge wear that’s hard to see with the naked eye.

Using magnification or digital inspection tools can help spot wear early. Operators should also look for indirect signs: changes in sound, vibration, surface finish, or burr formation.

Early detection prevents part rework, tool breakage, and production delays.

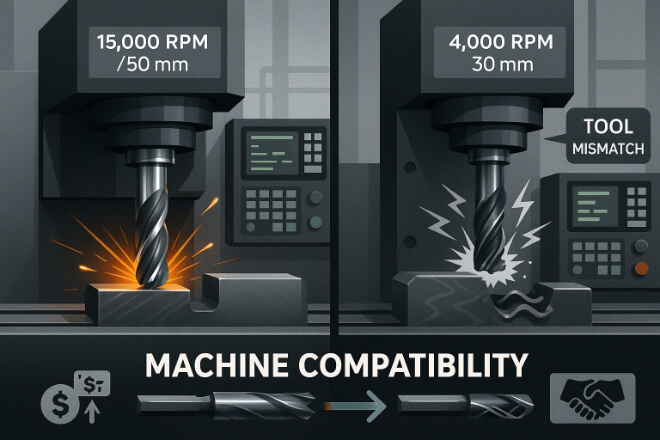

Myth 7: One Tool Fits All Machines

Reality: Different machines have different power levels, spindle speeds, and capabilities.

A tool that works perfectly on one CNC setup may perform poorly on another.

For example, high-performance carbide end mills may require high RPMs to work efficiently. Using them on a low-speed machine could lead to rubbing instead of cutting, reducing tool life.

Tool selection should always consider the machine’s limitations.

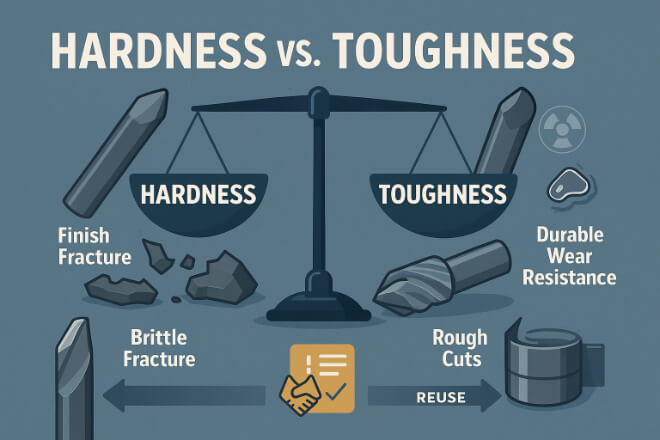

Myth 8: Higher Hardness Always Means Better Tools

Reality: While hardness is important, it’s not the only factor. A very hard tool may be brittle and prone to chipping in rough cuts or unstable setups.

In many cases, a balance of 硬度 and toughness is more effective.

Tungsten carbide tools with moderate hardness and strong binders perform better in roughing operations. For finishing or dry cutting, a harder, coated tool may be better.

Tool life depends on application, not just hardness.

Myth 9: Carbide Tools Can’t Be Recycled

Reality: Tungsten carbide is one of the most recyclable tool materials in the industry.

Many suppliers offer buy-back programs or reprocessing services. Recycling reduces environmental impact and lowers raw material costs.

Reground carbide tools can often perform just as well as new ones—if sharpened and recoated properly. This makes carbide tools both sustainable and economical.

Myth 10: Buying the Cheapest Tool Saves Money

Reality: Cheap tools usually wear out faster, break more easily, and lead to poor part quality. This increases downtime, rework, and even machine damage.

Investing in quality carbide tools may cost more upfront, but it delivers better results. Less scrap, fewer tool changes, and better productivity lead to real cost savings.

11. How to Make Smarter Tooling Decisions

If you’re responsible for purchasing or production planning, understanding these myths can help you avoid costly mistakes. Here’s what smart buyers and engineers do:

Evaluate tools based on total cost per part, not just price.

Choose carbide tools that match your material, machine, and process.

Work with trusted suppliers who offer technical support and tool customization.

Track tool performance over time to find the best ROI.

最後に

Tungsten carbide cutting tools have become the industry standard for a reason: they’re strong, reliable, and precise. But to get the most value, you need to understand how they work—and what they’re not.

Don’t fall for myths. With the right knowledge and the right tools, your shop can cut costs, boost productivity, and stay competitive.

Looking for better performance in your machining operations? Visit リトプズ for tools built to last and advice you can trust.