鋼鉄とは何ですか?

鋼は主に鉄と炭素から作られる合金で、性能を向上させるためにクロム、ニッケル、マンガンなどの他の元素が加えられることが多いです。

鋼は強度、靭性、汎用性に優れているため人気があります。また、タングステンカーバイドに比べて機械加工や溶接が容易で、コストも安価です。

鋼の主な特性:

高い 強靭さ そして強さ

機械加工や成形が容易

大型部品のコスト効率に優れています

用途に応じた異なるグレード(例:工具鋼、ステンレス鋼、高炭素鋼)

鋼は、ギア、シャフト、構造部品、一般的なエンジニアリング部品に広く使用されています。

炭化タングステンと鋼の特性比較

| 財産 | タングステンカーバイド | 鋼鉄 |

|---|---|---|

| 硬度 | 非常に高い(8.5~9モース硬度) | 低硬度(等級によって4~8モース硬度) |

| 耐摩耗性 | 優れた、研磨条件に最適 | 良いが、摩耗により早く消耗する |

| 耐熱性 | 非常に高く、高温でも硬度を維持します | 中程度、高温で硬度が失われる場合があります |

| 耐腐食性 | 高い(特にコーティングの場合) | ステンレス鋼は耐腐食性に優れています |

| 強靭さ | 中程度(強い衝撃を受けると欠ける場合があります) | 高い、衝撃荷重に強い |

| 加工性 | 困難、ダイヤモンドまたは超硬工具が必要 | 標準工具で簡単に加工可能 |

| 料金 | より高い | より低い |

過酷な条件下での耐久性

耐摩耗性と耐摩擦性に関しては、タングステンカーバイドが優れています。

鉱業や金属成形において、炭化タングステン製の工具や部品は、鋼製の同等品に比べて3~10倍も長持ちすることがよくあります。これにより、ダウンタイムと交換コストが削減されます。

ただし、部品が強い衝撃や曲げ力にさらされる場合、鋼鉄はタングステンカーバイドよりも優れた性能を発揮することがあります。

鋼鉄は高い 強靭さ つまり、ひび割れることなく衝撃を吸収できるため、一部の構造用途に適しています。

コストに関する考慮事項

一見すると、タングステンカーバイド製の部品は鋼鉄製よりも高価に見えます。しかし、交換、ダウンタイム、メンテナンスを含むライフサイクル全体のコストを考慮すると、タングステンカーバイド製の方が経済的になる場合が多くあります。

たとえば、タングステンカーバイド製の切削ダイはスチール製のダイよりも 2 ~ 3 倍高価ですが、5 ~ 10 倍長持ちするため、多くの場合、より良い投資となります。

アプリケーション適合性

1). タングステンカーバイドを使用する場合:

極度の摩耗と擦り切れ

高温

精密公差

最小限のダウンタイムで連続運転が可能

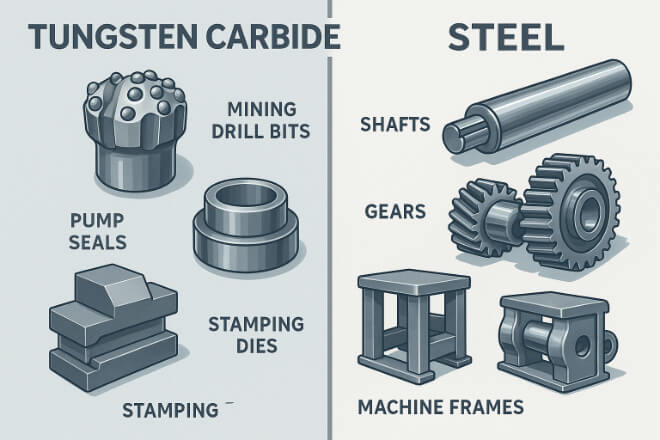

1.1) 例:

鉱山用ドリルビット

ポンプシール 石油・ガス

金属打ち抜き金型

木工用刃

2). スチールを使用する場合:

大きな衝撃荷重と曲げ

低温環境

コストが重要な要素となるアプリケーション

炭化物では高価すぎる大型部品

2.1) 例:

機械フレーム

シャフトとギア

一般的な構造部品

長所と短所のまとめ

| 材料 | 長所 | 短所 |

|---|---|---|

| タングステンカーバイド | 優れた耐摩耗性、高硬度、優れた耐熱性と耐腐食性、長寿命 | 高価、強い衝撃に弱い、機械加工が難しい |

| 鋼鉄 | 高靭性、低コスト、機械加工が容易、多用途 | 耐摩耗性が低く、高温で硬度が失われる可能性があり、メンテナンスが必要になります |

炭化タングステンと鋼の選択

適切な材料の選択は、次の要素に依存します。

摩耗の種類 – 研磨、接着、衝撃、腐食

動作温度 - 高熱プロセスでは炭化物が必要になる場合があります

部品サイズ – 大型部品の場合、鋼鉄の方が経済的です

耐用年数の要件 - カーバイドは交換頻度が少ないことを意味することが多い

予算 – 短期的コスト計画と長期的コスト計画

多くの業界にとって、最善のアプローチは、構造サポートに鋼を使用し、摩耗面にタングステンカーバイドを使用するという組み合わせです。

パフォーマンスを最大化するためのメンテナンスのヒント

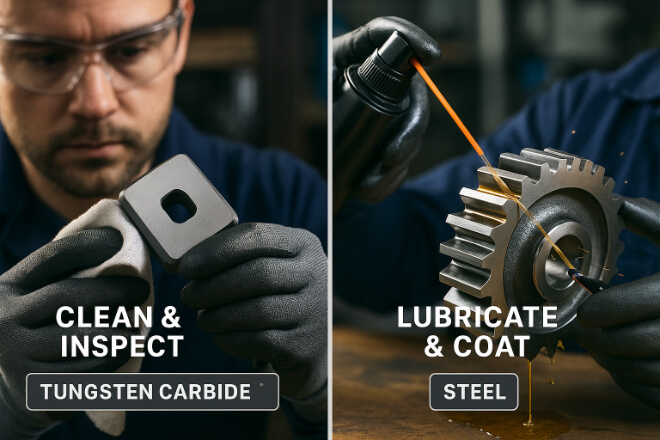

1). タングステンカーバイドの場合:

突然の衝撃を避ける

応力亀裂を防ぐために適切な取り付けを行う

化学物質による腐食を防ぐために定期的に清掃してください

2)鉄鋼の場合:

耐腐食性のために保護コーティングを施す

潤滑を維持して摩耗を減らす

定期的にひび割れや変形がないか確認してください

結論

タングステンカーバイドと鋼鉄のどちらが優れているかという議論には、明確な勝者はありません。タングステンカーバイドは耐摩耗性と高温用途において優位に立っており、鋼鉄は構造用途や衝撃の大きい用途において、靭性とコスト面で優位性があります。

意思決定者は、総所有コスト、性能要件、そして動作条件を比較検討する必要があります。多くの場合、両方の素材を単一のシステムに組み合わせることで、耐久性と強度という両方の長所を兼ね備えたシステムを実現できます。

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。