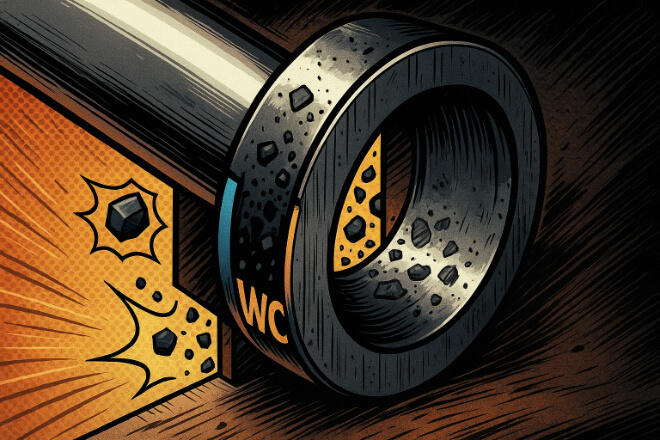

タングステンカーバイドブッシング ポンプ、コンプレッサー、スラリーシステムで広く使用されている。 摩耗に耐える ほとんどの素材よりも優れています。.

しかし、流体中に研磨粒子が存在する場合、タングステンカーバイドであっても限界があります。これらの粒子のサイズ、硬度、濃度は、ブッシングの寿命に大きな影響を与えます。.

この記事では、研磨粒子のサイズが摩耗にどのような影響を与えるか、意思決定者が注意すべきしきい値、実際のアプリケーションで損傷を軽減する方法について説明します。.

炭化タングステンブッシングにおいて研磨粒子サイズが重要な理由

研磨摩耗は、硬い粒子がシャフトとブッシング表面の間で滑り合うことで発生します。炭化タングステンは非常に硬いですが、粒子が十分に大きくなると切削工具のように機能します。.

1). 粒子が大きいほど摩耗が早くなる

大きな粒子はより深い傷を作る

潤滑膜を遮断する

摩擦と熱を増加させる

2) 小さな粒子でも有害

特に高速サービスや境界潤滑の場合には、微粒子であってもゆっくりと、しかし継続的に物質を除去することができます。.

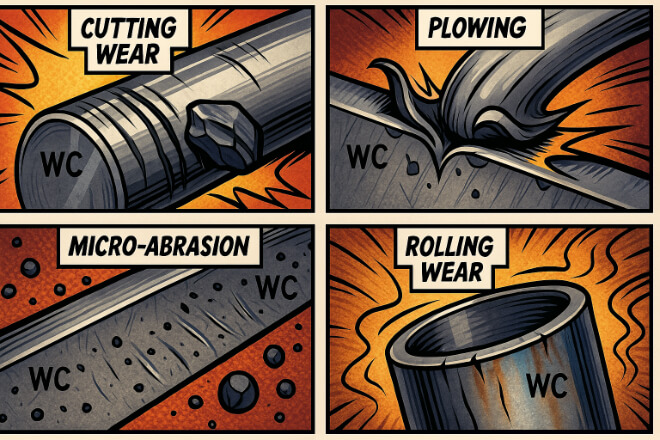

粒子サイズが摩耗メカニズムに与える影響

摩耗は単一のメカニズムではなく、粒子のサイズや 硬度. WC ブッシングの一般的な現象は次のとおりです。

切削摩耗: 大きな粒子が表面を直接削ります。.

耕起摩耗: 中程度の粒子が材料を押しのけて尾根を形成します。.

微細摩耗: 小さな粒子が非常に細かい傷を形成します。.

転がり摩耗: 丸い粒子は切削するのではなく転がり、摩耗率を低減します。.

| 粒子サイズ | 摩耗メカニズム | WCブッシングへの影響 |

|---|---|---|

| 大きい(>150 μm) | 切断 | 急速で激しい摩耗 |

| 中(50~150μm) | 耕作 | 中程度の摩耗、溝 |

| 大丈夫 (<50 μm) | マイクロアブレーション | ゆっくりだが継続的な摩耗 |

| 非常に良い(<10μm) | 圧延・研磨 | 高濃度でない限り摩耗が少ない |

WCブッシングの寿命に影響を与える粒子サイズの閾値

業界によって流体の清浄度は異なります。以下は、研磨用途におけるタングステンカーバイドの一般的なガイドラインです。.

| 粒子サイズ | リスクレベル | 期待される影響 |

|---|---|---|

| 25μm未満 | 低い | 主に微細な研磨摩耗 |

| 25~75μm | 中くらい | 経年劣化が目立つ |

| 75~150μm | 高い | 深い傷、短い寿命 |

| > 150 μm | 厳しい | 急速な摩耗、早期故障 |

これらのしきい値は、次の要因に応じて変化します。

システム圧力

粒子の硬さ

シャフトスピード

潤滑品質

ブッシング形状

粒子の硬度が摩耗の深刻度に与える影響

粒子の大きさは、ほんの一部に過ぎません。硬度は、粒子が炭化タングステンをどれだけ容易に切断できるかを決定します。.

硬度比較(標準値)

珪砂:1100~1200 HV

アルミナ:1500~2000 HV

タングステンカーバイド:1600~2000 HV

粒子がWCに近づいたり、WCを超えたりすると 硬度, 、摩耗はさらに激しくなります。.

| 粒子タイプ | 相対硬度 | 摩耗リスク |

|---|---|---|

| シリカ(砂) | WCより低い | 適度 |

| アルミナ | 同等以上 | 高い |

| 石英スラリー | トイレに近い | 高~重度 |

| 金属片 | 様々 | 傷やえぐれを引き起こす可能性がある |

濃度:たとえ小さな粒子であっても、大量に発生すると危険になる理由

単一の粒子では WC ブッシングが損傷しないかもしれませんが、数百万個の粒子が継続的に隙間を通過すると、サンドブラスト システムのように動作する可能性があります。.

高濃度の原因:

1秒あたりの粒子衝突数の増加

潤滑膜の破壊が早まる

表面温度の上昇

摩耗溝の発達の促進

高速ポンプと撹拌機は粒子の濃度に特に敏感です。.

異なる粒子サイズによって引き起こされる現実世界の摩耗パターン

あらゆる研磨環境は、ブッシングの穴に独特の痕跡を残します。.

典型的な摩耗パターン

| 粒子サイズ | 典型的な摩耗パターン | 解釈 |

|---|---|---|

| 25μm未満 | 上質なマットな表面 | マイクロアブレーション |

| 25~100μm | 目に見える溝 | 耕作摩耗 |

| 100~200μm | 深い傷 | 切削摩耗 |

| > 200 μm | チャンク除去、高スコアリング | 深刻な被害 |

タングステンカーバイドブッシングの摩耗を低減する方法

摩耗を軽減するために、必ずしもシステムの再設計が必要なわけではありません。多くの場合、小さなプロセス改善が大きな効果をもたらします。.

主要戦略

より良いろ過装置や沈殿物トラップを設置する

クリアランスを減らして粒子の侵入を制限する

より硬いグレードのタングステンカーバイドを選択する

滑らかでよく磨かれたシャフト表面を使用する

潤滑の流れを改善する

隙間に粒子を引き込むポンプのキャビテーションを回避する

研磨スラリーサービスに適したWCグレードの選択

WCグレードによって、 耐摩耗性. 研磨環境では通常、より細かい粒子と高い硬度が好まれます。.

| WCグレードタイプ | 最適な用途 | 注記 |

|---|---|---|

| 細粒WC-Co | ひどい擦り傷 | 非常に高い硬度 |

| サブミクロンWC | 高速スラリー | 優れた耐摩耗性 |

| WC-Ni | 腐食性スラリー | 優れた耐食性 |

| バインダーレストイレ | 極度の摩耗 | 最高の硬度 |

結論

研磨粒子のサイズは、タングステンカーバイドブッシングの寿命に影響を与える最も重要な要因の 1 つです。.

粒子のサイズ、硬度、濃度がどのように相互作用するかを理解することにより、オペレーターはろ過、クリアランス、潤滑、WC グレードの選択に関する実用的なしきい値を設定できます。.

適切な制御により、過酷なスラリー環境でもブッシングの寿命を大幅に延ばすことができます。.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。