パルプ、紙、黒液サービスにおける課題

研磨性のパルプ繊維は標準シールを急速に摩耗させます。

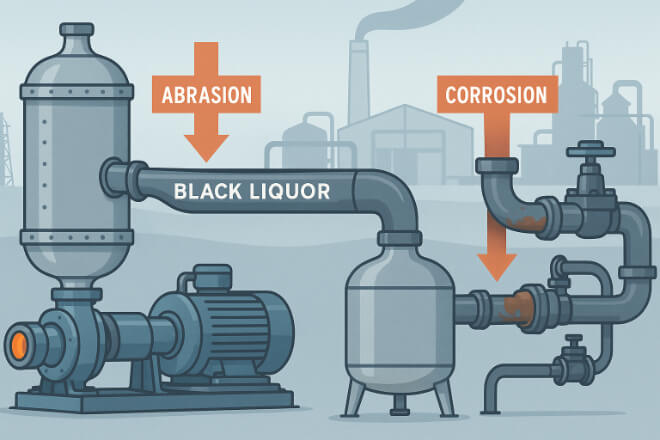

パルプ製造の副産物である黒液は、アルカリ性が強く、腐食性が高いです。

化学物質回収ボイラーおよび蒸発器内の高温により、機器に負担がかかります。

継続的な運用により、ダウンタイムはコストと混乱を招きます。

ステンレス鋼やカーボングラファイトシールは、多くの場合、このような条件には十分な強度がありません。 超硬シールリング 必要な強度と信頼性を提供します。

パルプおよび紙加工における応用

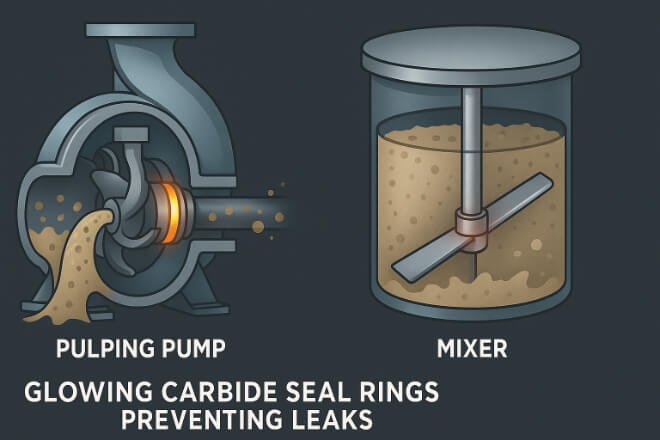

1). パルプポンプ

超硬シールリング 研磨パルプ混合物を移送するポンプの漏れを防止します。

2). 精製業者とミキサー

連続的な混合と精製には、摩擦を減らして摩耗に耐えるシールが必要です。

3). 漂白システム

腐食性の漂白化学薬品では、カーバイドリングが信頼性の高いシールを確保します。

黒酒サービスにおける応用

1). 黒液蒸発装置

カーバイドシールは、高濃度で腐食性のある黒液を扱う蒸発器の漏れを防止します。

2). 回収ボイラー

シールリングは高熱と化学攻撃の組み合わせに耐えます。

3). 化学物質回収回路

耐久性のある炭化物リングにより、黒液をリサイクルするシステムの信頼性が向上します。

パルプ・製紙業界へのメリット

| 利点 | 説明 |

|---|---|

| 長寿命 | 研磨性パルプや腐食性アルコールに耐性があり、交換回数を減らします。 |

| ダウンタイムの短縮 | シールの故障が減ることで、設備の稼働と生産が安定します。 |

| 安全性の向上 | 作業員に危害を及ぼす可能性のある高温の腐食性黒液の漏れを防ぎます。 |

| コスト効率 | メンテナンスと交換が減るため、総所有コストが削減されます。 |

| プロセスの信頼性 | 安定したシーリングにより、一貫したパルプおよび紙の生産品質が維持されます。 |

ケーススタディ

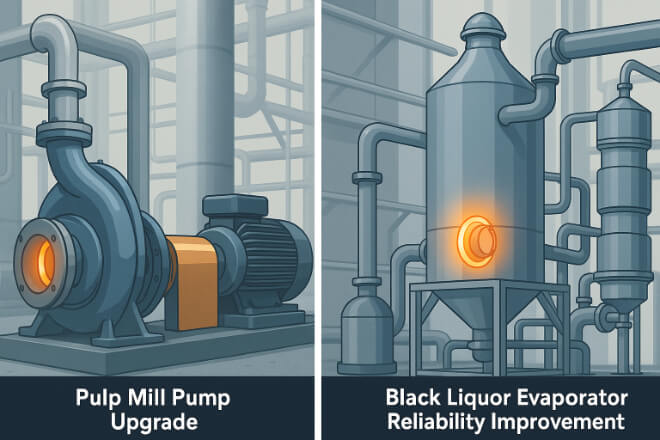

1). パルプ工場ポンプのアップグレード

あるパルプ工場では、ステンレス鋼製のシールをニッケル結合カーバイドリングに交換しました。その結果、シール寿命が2倍になり、計画外メンテナンスの回数が40%減少しました。

2). 黒液蒸発器の信頼性

ある製紙工場では、黒液蒸発器にカーバイドリングを採用しました。その結果、漏れが減少し、環境コンプライアンスが向上し、運用コストも削減されました。

適切な超硬シールリングの選び方

1). バインダーの種類

腐食性の黒液および漂白化学薬品用のニッケル結合炭化物。

撹拌機およびパルプポンプの衝撃荷重に耐えるコバルト結合炭化物。

2)表面仕上げ

研磨された炭化物表面は回転機器の摩擦と摩耗を軽減します。

3). 動作条件

グレードを選択するときは、温度、圧力、化学物質への暴露を考慮してください。

4). サプライヤーの専門知識

パルプおよび紙のアプリケーションでの経験を持つ ISO 認定サプライヤーを選択してください。

メンテナンスと交換戦略

計画的なシャットダウン中に、シール部分に亀裂、溝、腐食がないか検査します。

生産損失を避けるために、漏れが発生する前に摩耗したリングを交換してください。

重要なポンプやミキサー用に予備のカーバイドシールを在庫しておいてください。

使用済みの超硬部品をリサイクルして、コストと環境への影響を削減します。

コストとROIの考慮

初期コスト: 標準シールよりも高くなります。

節約: 漏れとダウンタイムの削減により収益性が向上します。

ROI: 耐用年数の延長と信頼性の向上により、投資が正当化されます。

環境と安全上の利点

黒液の漏洩を防ぐことは、河川、地下水、そして工場労働者の安全を守ることにつながります。カーバイドシールは、工場が環境規制を遵守し、安全な職場環境を維持するのに役立ちます。

結論

超硬シールリングは、パルプ、製紙、黒液処理に不可欠です。その硬度、耐腐食性、そして耐久性は、過酷な環境に最適な選択肢です。

意思決定者にとって、カーバイドシールは、故障の減少、メンテナンスコストの削減、安全性の向上、生産品質の安定を保証します。これらはパルプおよび製紙業界で競争力を維持するための重要な要素です。

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。