タングステンカーバイドブッシング are used in some of the toughest working conditions — inside pumps, compressors, turbines, and drilling tools.

Their main job is to reduce friction and provide stable support for rotating shafts.

Although tungsten carbide is extremely hard and durable, it is not indestructible. Improper use, poor lubrication, or incorrect fitting can lead to premature failure.

Understanding these failure modes helps engineers and decision-makers extend service life and reduce maintenance costs.

This article explains the most common failure types in tungsten carbide bushings, their root causes, and practical ways to avoid them.

Why Failure Analysis Matters

When a bushing fails, it can damage other expensive components — such as shafts, seals, or bearings. It also leads to unplanned downtime and higher repair costs.

By studying failure patterns, companies can:

Improve equipment reliability

Extend service intervals

Choose better materials or coatings

Enhance lubrication and cooling systems

In short, knowing why a bushing fails is the first step toward making it last longer.

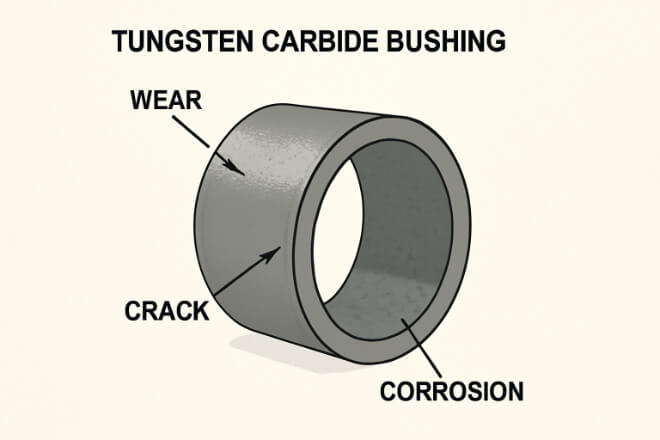

Wear and Abrasion

Wear is the most common failure mode in tungsten carbide bushings.

It happens when hard particles, friction, or insufficient lubrication cause material loss from the surface.

| Type of Wear | Main Cause | Typical Symptoms | Prevention Method |

|---|---|---|---|

| Abrasive Wear | Hard particles between shaft and bushing | Surface grooves or scratches | Use fine filtration and clean lubrication |

| Adhesive Wear | Metal-to-metal contact under poor lubrication | Material transfer or surface welding | Ensure correct oil film and shaft alignment |

| Erosive Wear | Fluid with solid or chemical contaminants | Rounded edges, dull surface texture | Choose harder grade or apply protective coating |

How to avoid it:

Maintain proper lubrication and cooling.

Use fine filters to keep out contaminants.

Select harder tungsten carbide grades or coatings like DLC or TiN for abrasive environments.

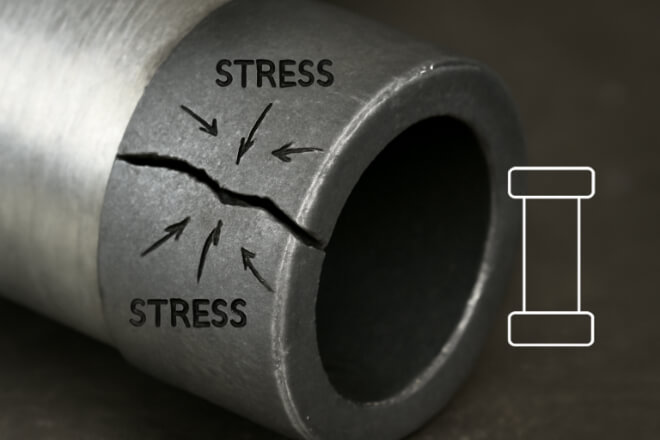

Fracture and Cracking

Cracking usually results from mechanical shock, stress concentration, or improper assembly.

Even though tungsten carbide is hard, it’s also brittle. Sudden impacts or uneven fitting can easily cause it to break.

1). Typical causes:

Interference fit too tight during press fitting.

Shaft misalignment creating uneven load.

Vibration or impact during operation.

2). Prevention:

Ensure correct interference tolerance during assembly.

Avoid hammering or forcing bushings into housing.

Support the bushing evenly to prevent bending stress.

A cracked bushing can’t be repaired — it must be replaced immediately to avoid further damage.

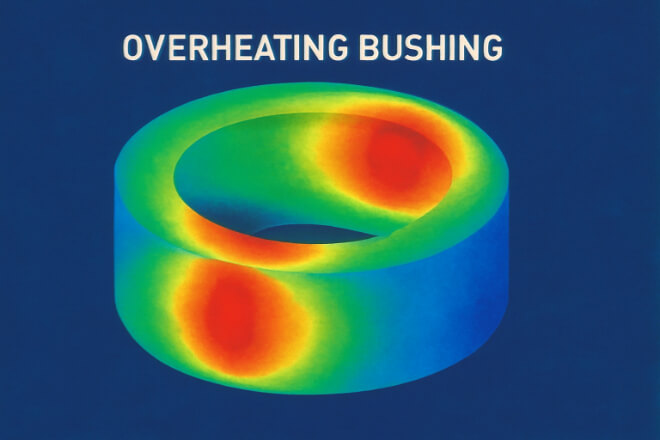

Thermal Damage

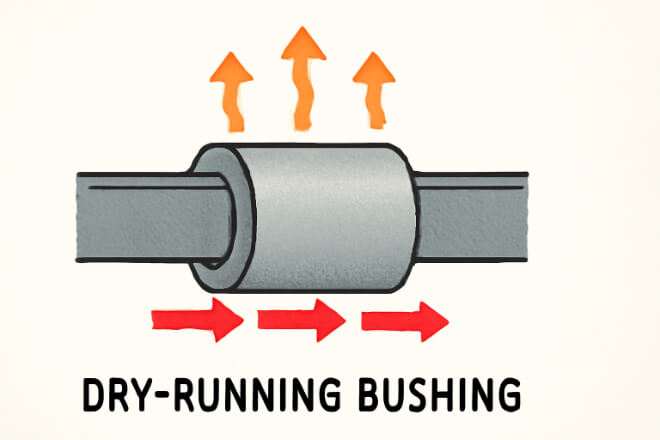

When temperature rises too high, tungsten carbide bushings may suffer thermal fatigue or binder softening.

This often happens in systems with poor cooling or dry running.

1). Signs of thermal failure:

Surface discoloration or micro-cracks.

損失 硬度.

Dimensional distortion.

2). How to prevent thermal damage:

Maintain proper lubrication and coolant flow.

Use Ni-binder carbide for better heat resistance.

Consider adding grooves or holes for coolant circulation.

Thermal stress is a silent killer that slowly reduces bushing life even before visible cracks appear.

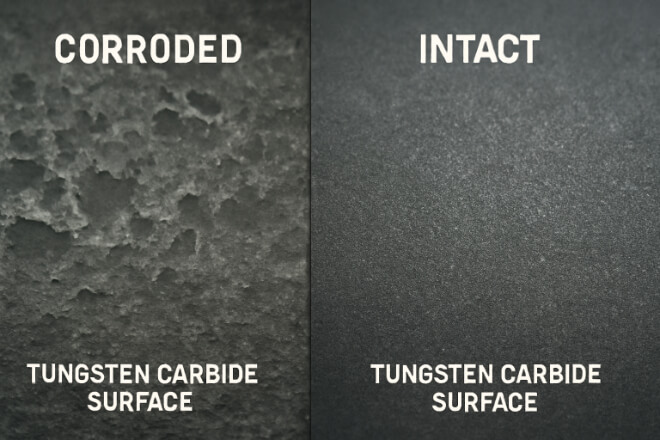

Corrosion and Binder Leaching

In pumps or compressors handling acids, seawater, or chemicals, the cobalt binder in tungsten carbide can dissolve, leaving the surface porous and weak.

1). Common causes:

Chemical attack on Co-binder phase.

Operation in high-humidity or corrosive gases.

Using wrong binder type for environment.

2). Prevention:

Use nickel-binder tungsten carbide (WC-Ni) for corrosive conditions.

Apply CrN coating for chemical protection.

Regularly check pH and chemical composition of fluids.

Binder leaching is often visible as gray patches or powdery spots on the bushing surface.

Fatigue Spalling

Fatigue spalling is a progressive failure caused by repeated stress over time.

Tiny cracks start below the surface and eventually cause small chips or flakes to break off.

1). It is common in:

High-speed shafts, oscillating loads, or vibration-prone applications.

2). Prevention:

Use fine-grained carbide for higher fatigue resistance.

Ensure shaft and bushing surfaces are well aligned.

Maintain balanced load and steady operation.

Once spalling begins, it tends to spread quickly. Early detection can prevent complete failure.

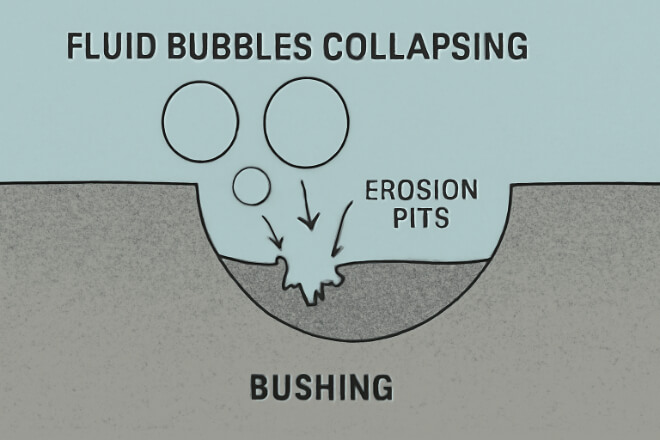

Cavitation Damage

Cavitation occurs when vapor bubbles in fluid collapse near the bushing surface, producing micro-jets that erode the material.

1). Typical in:

Hydraulic and water pumps with high-speed or low-pressure regions.

2). Symptoms:

Pitted or honeycomb-like surface.

Material erosion at fluid entry points.

3). Prevention tips:

Control pump pressure and avoid sudden suction changes.

Use smoother internal surfaces to reduce turbulence.

Select tougher carbide grades with good erosion resistance.

Poor Fit and Misalignment

Incorrect fitting between the shaft and bushing is a frequent cause of early failure. Too tight, and it causes stress; too loose, and vibration occurs.

1). Causes:

Wrong tolerance or machining error.

Thermal expansion differences.

Inaccurate housing bore.

2). Solutions:

Follow recommended fitting tolerances (H6/g5 or similar).

Heat housing and cool bushing for shrink fitting.

Verify alignment with dial indicators after installation.

Proper installation is as important as material quality when it comes to long-term reliability.

Lubrication Failure

Insufficient lubrication leads to direct metal contact, resulting in rapid wear and heat buildup.

1). Common causes:

Clogged lubrication line.

Wrong lubricant viscosity.

Overheating causing oil breakdown.

2). Prevention:

Use correct lubricant type and viscosity.

Check oil flow and cleanliness regularly.

Add grooves or oil holes for better distribution.

For high-speed applications, consider self-lubricating bushings or DLC-coated surfaces that minimize friction.

Improper Material or Grade Selection

Choosing the wrong tungsten carbide grade for the job can reduce service life dramatically.

For example, using a coarse-grain grade in a fine, high-speed environment may cause chipping or cracking.

| Operating Condition | Recommended Grade | バインダータイプ | Reason |

|---|---|---|---|

| Corrosive Fluid | WC-Ni Fine Grain | Nickel | Better chemical resistance |

| High Load & Impact | WC-Co Medium Grain | Cobalt | Higher toughness |

| High Speed & Low Load | WC-Co Fine Grain | Cobalt | Improved surface finish and hardness |

Selecting the correct grade during design ensures long-term reliability and better cost efficiency.

結論

Tungsten carbide bushings are built for strength and precision — but their performance depends on correct selection, installation, and maintenance.

By understanding and preventing failure modes such as wear, cracking, corrosion, and thermal damage, companies can maximize uptime, reduce repair costs, and extend bushing lifespan.

The key is to combine proper grade selection, accurate fitting, and consistent lubrication under controlled working conditions.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。