摩耗部品 are critical components in heavy machinery, manufacturing equipment, mining tools, and many other industrial systems. They are designed to take the most stress and wear during operation, protecting the rest of the machine from damage.

However, even the strongest materials—like tungsten carbide, hardened steel, and ceramics—can fail if they are not selected, maintained, or used correctly. Failures not only cause costly downtime but can also damage expensive machinery.

This article will explain the most common reasons wear parts fail and how to prevent these issues, helping decision-makers keep their equipment running longer and more efficiently.

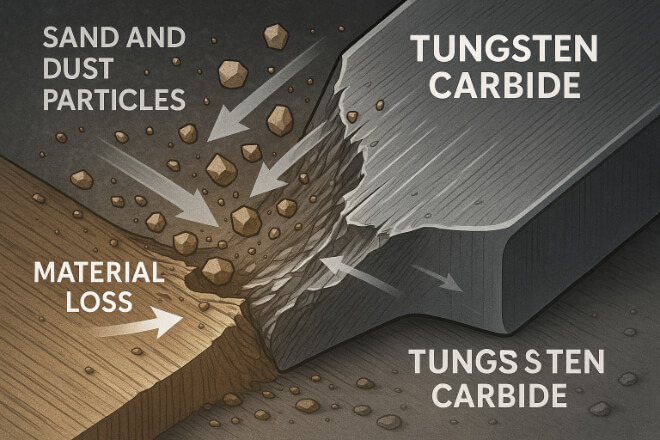

Abrasive Wear

1). What it is:

Abrasive wear happens when hard particles—such as sand, dust, or metal shavings—scrape or cut the surface of the wear part. Over time, this removes material and changes the shape of the part.

2). Causes:

Poor sealing, allowing debris to enter

Using a material with low hardness for the application

Inadequate cleaning or maintenance

3). Prevention:

Use harder materials like tungsten carbide for abrasive environments.

Improve sealing systems to block contaminants.

Keep equipment clean and free of abrasive particles.

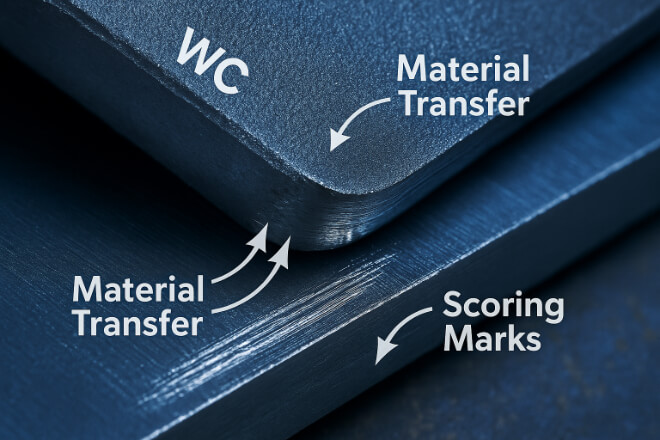

Adhesive Wear

1). What it is:

Adhesive wear occurs when two surfaces rub together and small fragments of material stick and transfer between them. This can create rough spots, scoring, and early failure.

2). Causes:

Poor lubrication

Wrong material pairing

Excessive load or pressure

3). Prevention:

Use the correct lubricant for the application.

Select material combinations that resist adhesion.

Avoid running machinery without lubrication.

Corrosion Damage

1). What it is:

Corrosion weakens the binder metals or surface coatings of wear parts, leading to cracks, pitting, and material loss.

2). Causes:

Exposure to moisture, chemicals, or salt

Using a material not suited for the environment

Poor storage conditions

3). Prevention:

Select corrosion-resistant materials, such as nickel-bonded carbide.

Apply protective coatings like chromium carbide.

Use corrosion inhibitors in lubricants and coolants.

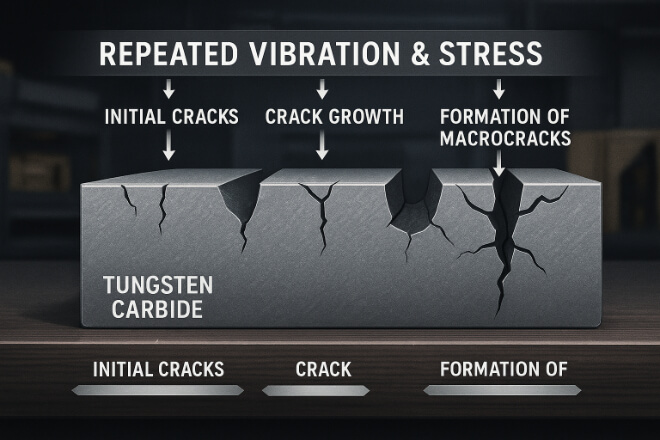

Fatigue Failure

1). What it is:

Fatigue failure happens when a part is exposed to repeated stress over time, even if the stress is below its maximum limit. Small cracks form and grow until the part breaks.

2). Causes:

Continuous impact or vibration

Poor alignment of components

Low-toughness material in a high-shock application

3). Prevention:

Use tougher carbide grades or alloy steels.

Maintain proper machine alignment.

Reduce vibration through balancing and proper setup.

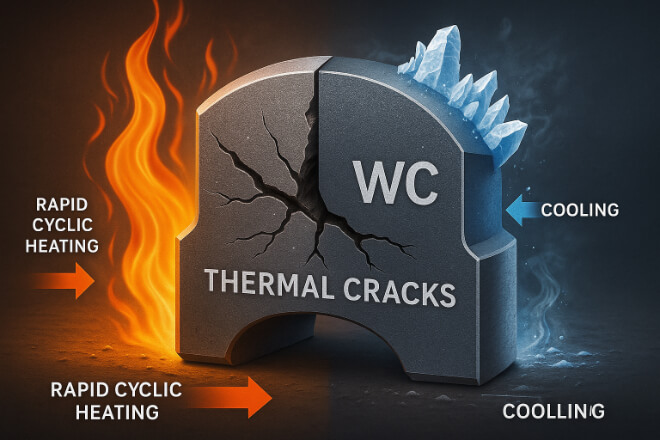

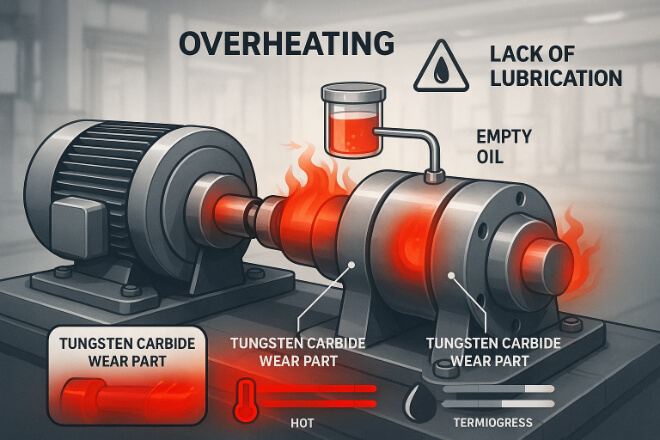

Thermal Cracking

1). What it is:

Thermal cracks appear when wear parts face rapid heating and cooling cycles. This causes expansion and contraction stress.

2). Causes:

Inadequate cooling

Overheating during operation

Sudden temperature changes

3). Prevention:

Use effective coolant systems.

Avoid dry running unless parts are designed for it.

Choose carbide grades designed for high-temperature work.

Impact Damage and Chipping

1). What it is:

Sharp edges or brittle materials can chip when hit by a hard object.

2). Causes:

Mishandling during installation

Running machines with loose parts

3). Prevention:

Use balanced grades with good toughness.

Train operators in safe handling practices.

Ensure all fasteners and fixtures are secure.

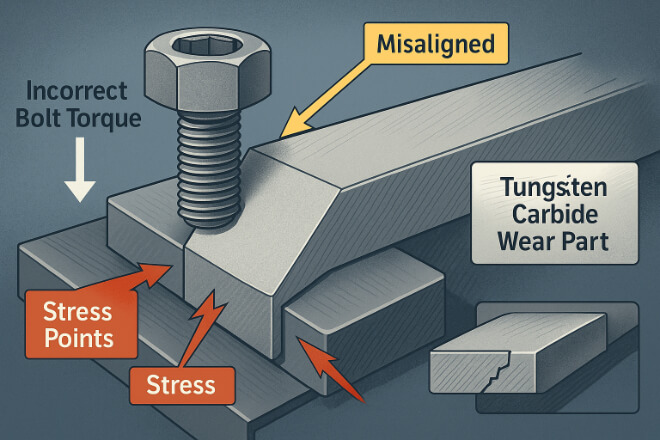

Improper Installation

1). What it is:

Even the best wear part will fail early if installed incorrectly.

2). Causes:

Misalignment during installation

Wrong fastening torque

Using damaged parts

3). Prevention:

Follow manufacturer installation guidelines.

Use proper tools and fixtures.

Inspect parts before installation.

Poor Lubrication Practices

1). What it is:

Without proper lubrication, friction increases, heat builds up, and wear accelerates.

2). Causes:

Using the wrong lubricant type

Irregular lubrication schedules

Contaminated lubricants

3). Prevention:

Create and follow a strict lubrication schedule.

Use only recommended lubricants.

Keep lubricant storage containers sealed and clean.

Common Failures & Prevention

| Failure Type | Main Cause | Prevention |

|---|---|---|

| Abrasive Wear | Hard particles scraping surface | Harder materials, better sealing, cleaning |

| Adhesive Wear | Material transfer between surfaces | Lubrication, correct materials |

| 腐食 | Chemical attack on binder | Resistant materials, coatings |

| Fatigue Failure | Repeated stress cycles | Tougher grades, alignment, vibration control |

| Thermal Cracking | Rapid heating and cooling | Coolant use, thermal-grade carbide |

| Impact Damage | Shock loading or mishandling | Tougher grades, safe handling |

| Improper Installation | Incorrect alignment or torque | Follow guidelines, inspect parts |

| Poor Lubrication | Friction and heat build-up | Lubrication schedule, correct lubricant |

Setting Up a Preventive Maintenance Program

1). Why it matters:

Preventive maintenance can catch small problems before they cause a breakdown.

2). Key steps:

Schedule regular inspections.

Keep detailed wear logs.

Replace parts before complete failure.

Partnering with the Right Supplier

Suppliers with technical expertise can recommend the right materials and designs for your application.

Benefits:

Access to advanced wear analysis.

Better quality control.

Custom part design for longer life.

結論

Most wear part failures are preventable with proper material selection, correct installation, adequate lubrication, and regular maintenance.

For decision-makers, preventing failures means more uptime, fewer replacements, and lower long-term costs.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。