In the manufacturing and machining industries, achieving optimal cutting performance is essential for maximizing productivity and minimizing costs.

タングステンカーバイドチップ are widely used for their exceptional 硬度, 耐摩耗性, and precision.

However, to get the best out of tungsten carbide tools, it’s important to know how to optimize their performance.

In this blog, we will explore strategies to improve cutting efficiency, prolong tool life, and enhance overall machining processes with tungsten carbide tips.

Understanding Tungsten Carbide Tips and Their Cutting Advantages

Tungsten carbide tips are known for their superior cutting capabilities, which is why they are favored in industries requiring high-performance tools, such as 金属加工, 採掘、 そして 自動車 製造業。

1). Why Tungsten Carbide Tips Are Ideal for Cutting

硬度: Tungsten carbide is extremely hard, which allows the tips to maintain sharp cutting edges for longer periods.

耐摩耗性: These tips resist wear from abrasives, which helps reduce the frequency of tool replacements.

耐熱性: Tungsten carbide can withstand high temperatures, making it ideal for high-speed cutting operations.

精度: Carbide tips maintain precision over extended use, ensuring consistent cuts and high-quality results.

These attributes make tungsten carbide tips a popular choice for various cutting applications.

However, to achieve the best performance, certain techniques and practices must be followed.

Optimize Cutting Conditions for Maximum Performance

One of the most effective ways to enhance the performance of tungsten carbide tips is by optimizing the cutting conditions.

The right combination of cutting speed, feed rate, and depth of cut can lead to better results and longer tool life.

1). Adjust Cutting Speed

The cutting speed refers to the speed at which the cutting edge of the tool moves relative to the material being cut.

For tungsten carbide tips, operating within the recommended cutting speed range is crucial:

Too Low: If the cutting speed is too low, the tool may experience unnecessary wear and tear, leading to reduced efficiency.

Too High: If the cutting speed is too high, it can cause overheating, resulting in tool damage and poor-quality cuts.

Operating within the optimal speed range ensures the carbide tips work efficiently and last longer.

2). Feed Rate

The feed rate is the speed at which the material is moved past the tool.

An appropriate feed rate ensures that the tool does not become overloaded, which can cause excessive wear or breakage.

Too fast a feed rate can lead to poor surface finishes and tool damage, while too slow a feed rate can cause excessive heat buildup and reduce tool life.

3). Depth of Cut

The depth of cut determines how much material is removed during each pass of the tool.

Deeper cuts generate more heat and stress on the tool, so it’s important to balance depth with cutting speed and feed rate.

Shallow cuts may prolong tool life but could reduce cutting efficiency, so finding the right balance is key.

By optimizing these cutting parameters, you can maximize the performance and lifespan of your tungsten carbide tips.

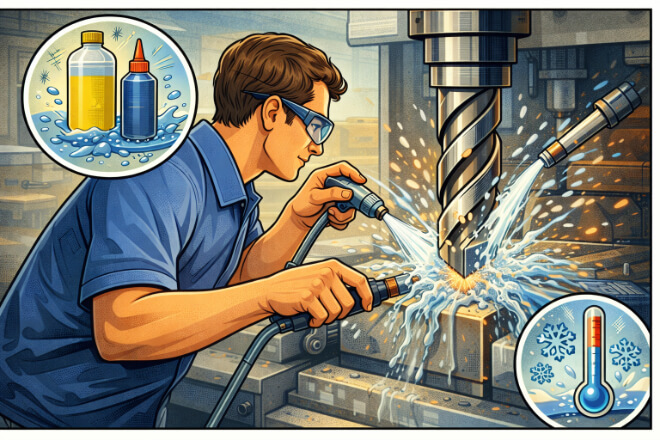

Maintain Proper Tool Cooling and Lubrication

Coolant and lubrication play a critical role in maintaining the performance of タングステンカーバイドチップ during cutting operations.

1). Coolant Use

The application of coolant helps prevent overheating, which can cause thermal damage to carbide tools.

A consistent flow of coolant reduces friction and dissipates heat, which helps prolong the life of the tool and ensures that the cutting edges stay sharp.

Water-Based Coolants: These coolants are effective in reducing heat buildup and improving surface finish.

Oil-Based Coolants: These are used for heavier cutting operations and help in reducing friction and tool wear.

Make sure to use the appropriate coolant for the materials being cut and ensure proper cooling throughout the operation.

2). Lubrication

Lubrication not only cools the cutting area but also reduces friction between the tool and the material. This can lead to smoother cuts, reduced wear, and increased tool life.

Using the right type of lubricant can make a significant difference in the cutting process, especially when working with difficult-to-machine materials.

Proper Tool Maintenance for Longer Life

To ensure tungsten carbide tips remain effective and durable, proper maintenance is crucial.

Regular inspections and reconditioning can help extend the lifespan of carbide tools.

1). Routine Inspections

Inspecting the carbide tips regularly for signs of wear, cracks, or chips will allow you to take corrective action before tool failure occurs.

Identifying wear early can help you decide whether reconditioning or sharpening is necessary, which is far less expensive than replacing the tool altogether.

2). Reconditioning and Sharpening

Tungsten carbide tips can often be reconditioned and sharpened to restore their cutting effectiveness.

Proper reconditioning not only saves money but also reduces the environmental impact by reusing materials.

3). Proper Storage

When not in use, carbide tips should be stored properly to prevent damage.

Keeping tools in a dry, clean environment can prevent corrosion and deterioration, helping to maintain their sharpness and durability.

By investing in regular maintenance, businesses can ensure that their tungsten carbide tips provide the best performance over a longer period.

Selecting the Right Tungsten Carbide Tips for Your Application

The key to optimizing cutting performance is choosing the right tungsten carbide tips for your specific application.

Not all carbide tips are the same, and selecting the proper grade and geometry for your cutting operation can make a significant difference.

1). Tip Geometry

The geometry of the carbide tip, such as the cutting angle, rake angle, and chip breaker design, affects how the tool interacts with the material.

Choosing the right geometry for the material being cut can improve cutting efficiency, reduce tool wear, and produce better surface finishes.

2). Grade of Tungsten Carbide

Different grades of tungsten carbide are designed for specific applications. Higher-grade carbide tips offer superior performance but at a higher cost.

For general-purpose machining, a standard grade might suffice, but for specialized tasks, a higher-grade tip might be required to achieve optimal performance.

結論

Optimizing cutting performance with tungsten carbide tips involves more than just selecting high-quality tools.

By adjusting cutting conditions, ensuring proper cooling and lubrication, performing regular maintenance, and selecting the right carbide tips for your application, you can significantly improve tool life, reduce downtime, and boost overall productivity.

Investing in these strategies can lead to long-term savings and enhanced performance in your machining operations.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。