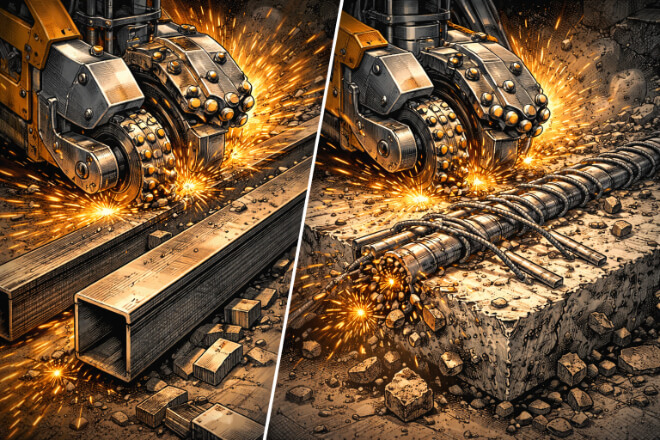

In industries that require tough cutting, such as 金属加工, 工事、 そして 自動車 manufacturing, the choice of cutting tool material can significantly impact efficiency, tool life, and operational costs.

Among the most commonly used materials for cutting tools are tungsten carbide, ceramic, and steel. Each material has unique properties that make it suitable for certain applications, but how do they compare in tough cutting jobs?

This blog will compare タングステンカーバイドチップ to ceramic and steel in terms of performance, durability, and cost-effectiveness in demanding cutting tasks.

Tungsten Carbide Tips: The Preferred Choice for Tough Cutting Jobs

Tungsten carbide is widely considered the best material for cutting tools used in tough applications.

Its unique properties make it highly effective in cutting through hard materials such as metals, concrete, and composites.

1). 優れた 硬度

Tungsten carbide is one of the hardest materials available, second only to diamond.

This hardness allows carbide tips to maintain a sharp cutting edge over extended periods, even when cutting through abrasive materials like steel, rock, and cement.

This sharpness ensures cleaner cuts with less effort, leading to more precise and efficient cutting.

2). Outstanding 耐摩耗性

Tungsten carbide tips excel in environments with high friction and wear.

Their resistance to abrasion and wear makes them perfect for tough cutting jobs, where steel and ceramic tools may degrade faster.

Carbide tips are less likely to lose their cutting efficiency, resulting in fewer tool replacements and reducing downtime in manufacturing environments.

3). Impact Resistance

Tungsten carbide tips are also highly resistant to impact forces, which is essential when cutting through tough or hard materials.

Their ability to withstand heavy shocks without breaking or chipping contributes to their reliability and extended tool life.

Ceramic Cutting Tools: High Precision but Limited Durability

Ceramic cutting tools offer high precision and hardness but may not perform as well as tungsten carbide in tougher cutting jobs.

While ceramics can handle precision cutting tasks, their brittleness limits their effectiveness in high-impact environments.

1). High 硬度

Ceramic materials are extremely hard and can provide sharp cutting edges for precise cutting jobs.

They are especially useful in applications that involve light to medium cutting tasks, such as fine machining or cutting softer metals.

However, when used on tough materials or in environments with high impact or heat, ceramic tools may wear down or break more quickly than tungsten carbide tools.

2). 耐摩耗性

Ceramics also have good wear resistance, but they tend to degrade faster in abrasive cutting tasks compared to tungsten carbide.

They are not as durable when cutting through tough materials like hard metals or concrete, where carbide tips perform much better.

3). Brittleness and Impact Resistance

One of the main drawbacks of ceramic tools is their brittleness.

While ceramics can withstand high temperatures, they are prone to breaking or chipping when subjected to heavy impacts or sudden forces.

This limits their effectiveness in industries like construction and heavy metalworking, where tools face constant shocks and vibrations.

Steel Cutting Tools: Versatile but Less Durable in Tough Jobs

Steel has been the traditional material for cutting tools due to its versatility and lower cost.

While it is suitable for many cutting tasks, steel does not perform as well in tough cutting environments compared to tungsten carbide.

1). Moderate Hardness

Steel is not as hard as tungsten carbide or ceramic, which means it tends to lose its cutting edge more quickly.

While it works well for softer materials and general-purpose cutting, steel tools may need frequent sharpening or replacement when used for tough tasks like cutting through hard metals or abrasive materials.

2). Wear and Heat Resistance

Steel has moderate wear and heat resistance. While it can handle a variety of materials, it tends to wear out faster in high-speed or high-precision cutting operations.

In environments with high temperatures and friction, steel tools may degrade more quickly compared to carbide tips, leading to more frequent replacements and higher operational costs.

3). Impact Resistance

Steel is relatively tough and can withstand moderate impact forces, making it suitable for general cutting tasks.

However, in tough cutting jobs where high-impact stresses are common, such as in heavy metalworking or construction, steel may not perform as well as tungsten carbide, which offers superior impact resistance and durability.

Comparing Tungsten Carbide, Ceramic, and Steel for Tough Cutting Jobs

The choice between tungsten carbide, ceramic, and steel cutting tools depends on the specific application and material being worked on.

Below is a comparison of how these materials perform in tough cutting jobs.

| 特徴 | タングステンカーバイド | セラミック | 鋼鉄 |

|---|---|---|---|

| 硬度 | Very high (second only to diamond) | 高い | 適度 |

| 耐摩耗性 | 素晴らしい | 良い | 適度 |

| Impact Resistance | 非常に高い | Low (brittle) | 適度 |

| 耐熱性 | 素晴らしい | 良い | 適度 |

| 料金 | 高い | 適度 | 低い |

| 耐久性 | 非常に高い | 適度 | Low to moderate |

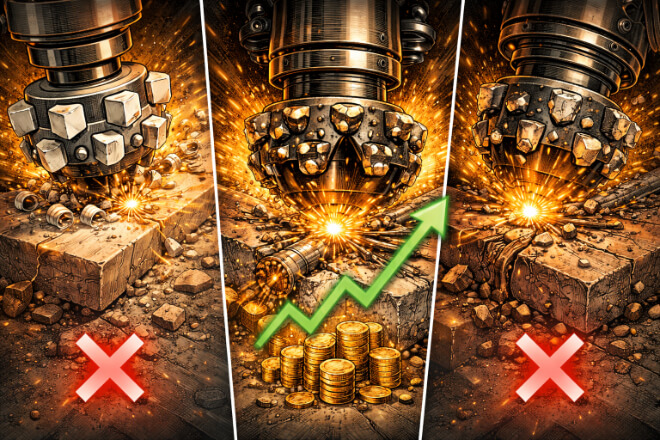

When to Choose Tungsten Carbide Tips Over Ceramic and Steel

Tungsten carbide is the preferred choice in tough cutting jobs when maximum durability, wear resistance, and impact toughness are needed.

It is ideal for industries that involve high-speed cutting, high-impact forces, or the processing of hard, abrasive materials like steel, concrete, and composites.

1). For High-Impact Applications

Tungsten carbide is the best option when cutting through materials that cause high impact stresses on the tools, such as when working with hard metals, rock, or reinforced concrete.

2). For High-Abrasive Materials

When working with abrasive materials like steel, sand, or stone, tungsten carbide tips provide superior wear resistance, making them the ideal choice for maintaining cutting efficiency over time.

3). For Long-Term Durability

If your operations require tools that need to last longer under heavy use, tungsten carbide tips offer the best long-term value, reducing the need for frequent tool changes and minimizing downtime.

結論

In tough cutting jobs, tungsten carbide tips offer significant advantages over ceramic and steel tools due to their superior hardness, wear resistance, and impact toughness.

While ceramic and steel tools can be effective for specific applications, they do not perform as well in high-stress, high-abrasion environments.

Tungsten carbide tips, on the other hand, provide long-lasting performance, reduced downtime, and improved cutting efficiency, making them the best choice for demanding cutting tasks in industries such as metalworking, construction, and automotive manufacturing.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。