炭化タングステン切削工具 are known for their strength, durability, and 耐摩耗性. But even the toughest tools won’t last forever without proper care.

If you want to get the most out of your carbide tooling—and avoid wasting time and money—you need the right maintenance habits.

This guide breaks down simple, practical tips to extend the life of your tungsten carbide cutting tools.

Whether you run a CNC shop or manage a small workshop, these strategies can help you reduce tool wear, improve performance, and keep your production running smoothly.

1. Keep Your Tools Clean

Dirty tools wear out faster. Chips, dust, and material build-up on your tool’s edge can cause more friction and heat, both of which lead to premature failure.

How to keep them clean:

Wipe down tools after use with a lint-free cloth.

Use gentle brushes to remove stuck chips.

Avoid using harsh chemicals that can damage coatings.

Store tools in clean, dry containers.

Regular cleaning ensures smoother cutting and extends tool life. Make it a habit.

2. Store Your Carbide Tools Properly

Tungsten carbide may be hard, but it’s not unbreakable. Poor storage can lead to chipped edges or surface damage, especially if tools knock against each other.

Tool storage tips:

Use padded or slotted storage boxes.

Never toss tools into drawers or bins.

Keep them away from moisture to avoid rust on non-carbide parts.

Label storage clearly to avoid handling errors.

Safe storage protects your investment and avoids unexpected failures on the machine.

3. Use the Right Tool for the Job

Not every carbide tool is made for every material or process. Using the wrong tool—like a finishing tool for roughing, or a tool made for plastic on hardened steel—will shorten its lifespan.

Match the tool to the job:

Use specific carbide grades for different materials.

Choose the right geometry for the cut (end mill, drill, insert, etc.).

Ensure proper coatings are used for heat resistance or lubrication.

4. Monitor Tool Wear Regularly

Don’t wait for a tool to break before replacing it. Regular inspections help you catch wear early and swap out tools before they damage your parts—or your machine.

What to look for:

Edge dullness or rounding

Chipping or fractures

Discoloration from heat

部品の表面仕上げが悪い

Use a magnifying glass or tool microscope for small tools. Keeping a simple wear log can also help you predict tool life more accurately over time.

5. Set Correct Speeds and Feeds

Carbide tools are tough, but they still need proper cutting parameters. Too much speed or too low a feed rate can cause unnecessary wear, overheating, and chipping.

Basic setup rules:

Follow the manufacturer’s speed/feed recommendations.

Use lower speeds for hard materials.

Don’t go too slow—this can cause rubbing instead of cutting.

Use constant engagement when possible.

A well-tuned cutting strategy keeps your tools performing longer.

6. Use Coolant or Lubrication When Needed

Heat is one of the main enemies of tool life. In operations where high temperatures build up quickly—such as drilling or milling metal—coolant is essential.

Why coolant matters:

Reduces heat buildup at the tool edge

Washes away chips that can cause abrasion

Prevents materials from sticking to the tool

Helps extend coating effectiveness

Flood coolant, misting systems, or even air cooling can all help, depending on the process.

Tip: Be sure to check if your tooling is designed for dry or wet machining. Not all carbide tools need coolant!

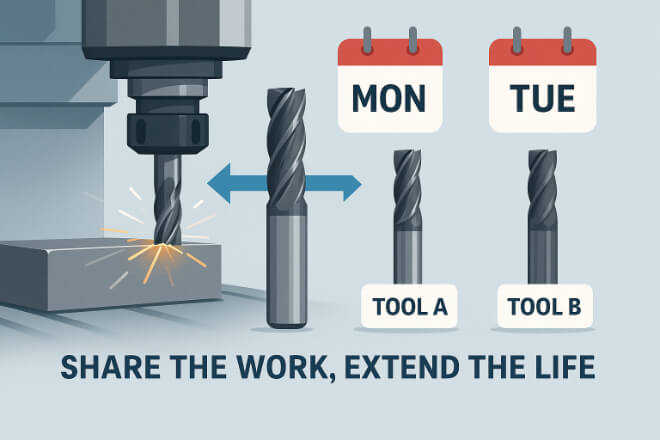

7. Rotate Tools to Share the Load

If you run the same tool nonstop until it fails, you’re pushing it too far.

Rotating multiple tools during long runs helps balance wear and avoid overuse.

How to do it:

Keep duplicate tools in your setup.

Switch them out every few hours or jobs.

Use tool life management features if your CNC has them.

By sharing the workload, you’ll keep tools sharper for longer and avoid unexpected tool failures.

8. Sharpen or Regrind When Possible

Some tungsten carbide tools can be reground to restore their cutting edges. This is especially true for end mills, inserts, and certain drills.

When to regrind:

The tool has dulled but isn’t chipped or cracked.

Geometry is still intact.

You can send it to a reliable grinding service.

Not all tools are worth regrinding—very small or complex tools may be better off replaced. But for larger or expensive tools, regrinding can give you great value.

9. Avoid Manual Abuse

Operators sometimes damage tools without realizing it—dropping them, forcing them into material, or tightening holders too much.

How to protect them:

Train staff on proper tool handling.

Use torque wrenches when installing tools.

Never try to “force” a tool to do something it’s not designed for.

Protecting your tools physically is just as important as optimizing performance.

10. Keep Maintenance Logs

A simple log or spreadsheet helps you track when tools were used, when they were cleaned, how long they lasted, and why they were retired.

Logging helps you:

Predict tool changes

Identify performance patterns

Reduce waste by reusing tools properly

Improve cost forecasting

You don’t need a complex system. Even a basic Excel sheet or whiteboard in your shop can go a long way.

11. Why Tool Maintenance Matters

Proper maintenance isn’t just about tool life—it’s about saving money. When tools last longer, you spend less on replacements.

When they cut cleanly, your parts are higher quality. When you avoid unexpected failures, your machines stay running.

A little care each day can mean hundreds or thousands saved over time. Carbide tools may cost more up front, but maintenance helps you get every penny of value.

最後に

Tungsten carbide cutting tools are a big investment—but with the right care, they’ll pay you back in durability, precision, and performance.

Just follow the basics: clean them, store them properly, match them to the right job, and stay on top of wear. These small steps go a long way in extending tool life and improving your machining results.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。