タングステンカーバイド摩耗部品 強さで知られている、 硬度、 そして 耐摩耗性など、多くの産業で使用されています。 採掘, 石油とガス、製造、木工。

最も頑丈な超硬部品であっても、時間の経過とともに摩耗します。企業は新品の部品に交換する代わりに、再生またはリサイクルを選択することでコストを節約し、環境を保護することができます。

この記事では、再生とリサイクルの仕組み、それらが重要な理由、そして業界の意思決定者が超硬部品から最大の価値を引き出すために知っておく必要があることについて説明します。

超硬摩耗部品の再生が重要な理由

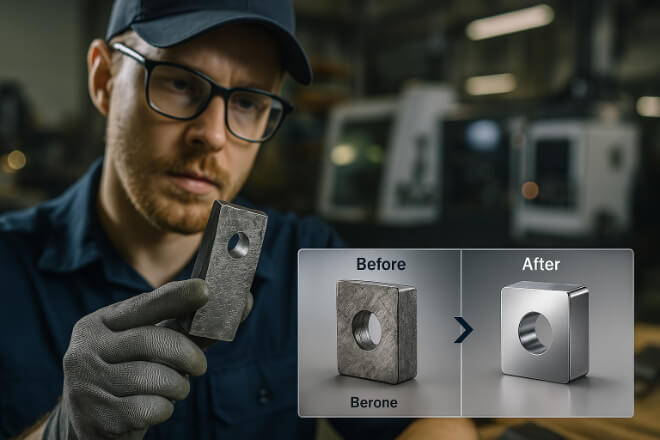

リコンディショニングとは、使用済みの摩耗部品を元の形状、サイズ、性能に戻すことを意味します。摩耗した部品を廃棄するのではなく、熟練した技術者が修理と表面処理を施します。

利点は次のとおりです:

コスト削減 – 再生は新しい部品を購入するよりも 30~70% 安くなります。

耐用年数の延長 - 適切に修復された部品は、新品とほぼ同じくらい長持ちします。

ダウンタイムの短縮 - 新しい部品の製造に比べてターンアラウンドが速くなります。

持続可能性 - 材料の無駄が少なくなり、環境への影響が少なくなります。

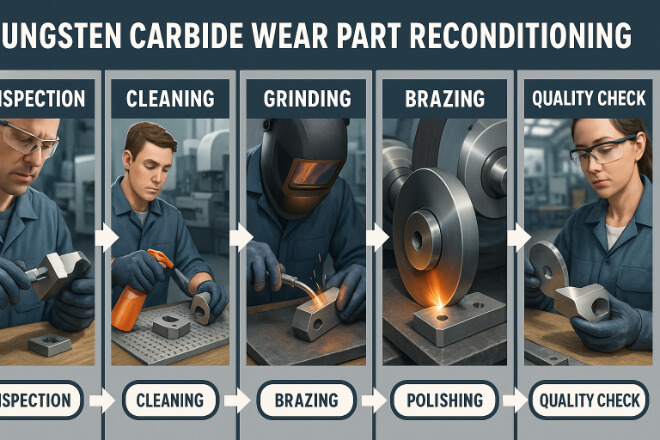

再調整プロセス

プロセスは炭化物摩耗部品の種類によって異なりますが、一般的には次のものが含まれます。

検査と評価 – 部品に亀裂、欠け、構造的な損傷がないか検査します。

清掃 – 汚れ、油、ゴミの除去。

研削と再成形 – 特殊な機械が正しい形状と許容誤差を復元します。

ろう付けまたは溶接(必要な場合) - 損傷した部分は互換性のある炭化物材料で再構築されます。

研磨とコーティング – 滑らかな仕上げが施され、保護コーティングが追加される場合もあります。

最終品質チェック – 部品をサービスに戻す前に寸法と性能が検証されます。

再生と交換のどちらを選ぶべきか

| 部品の状態 | 最良の選択肢 |

|---|---|

| 多少の摩耗あり、ひび割れなし | 再調整 |

| 中程度の摩耗、多少のエッジの欠けあり | 再調整 |

| ひどい摩耗、深い亀裂 | 交換する |

| 破損または欠落したセクション | 交換する |

炭化タングステン摩耗部品のリサイクル

リサイクルは再生とは異なります。使用済みの超硬合金部品を分解し、新しい製品の製造に使用できる原材料にすることです。

リサイクルの手順は次のとおりです。

収集 – 使用済みの超硬部品はさまざまな場所から集められます。

選別 – 炭化物を他の金属または材料から分離します。

処理 – 部品を粉砕、粉砕、または化学処理してタングステンとコバルトを回収します。

精製 – 不純物を除去して高純度のタングステン粉末を得ます。

改質 – 回収された炭化タングステンを使用して、新しい摩耗部品を製造します。

超硬部品のリサイクルの利点

コスト効率 - リサイクルされたタングステンは新しいタングステンの採掘よりも安価です。

資源の保全 – タングステンは有限の資源であり、リサイクルにより新たな採掘の必要性が減ります。

環境に対する責任 – 採掘が減れば生態系へのダメージも減ります。

企業の持続可能性目標 - 企業がグリーン製造目標を達成できるよう支援します。

最も恩恵を受ける産業

| 業界 | 一般的な超硬摩耗部品 | 再調整の可能性 |

|---|---|---|

| 鉱業 | ドリルビット、クラッシャーチップ | 高い |

| 石油・ガス | バルブシート、流量制御ツール | 中くらい |

| 金属加工 | 切削インサート、ダイス | 高い |

| 木工 | 鋸刃、かんな刃 | 高い |

意思決定者が価値を最大化する方法

業界リーダーにとって、再生とリサイクルのどちらを選択するかは、部品の状態、コスト、そして運用上のニーズによって決まります。ベストプラクティスのアプローチには以下が含まれます。

摩耗を早期に発見するための検査スケジュールを確立します。

信頼できる再生専門家と提携。

社内にカーバイドリサイクルプログラムを立ち上げる。

再生と交換によるコスト削減を追跡します。

結論

炭化物摩耗部品の再生とリサイクルは、企業のコスト削減、廃棄物の削減、貴重な資源の寿命の延長に役立ちます。

これらの実践を採用する意思決定者は、効率性を向上させ、持続可能性をサポートし、要求の厳しい産業環境において高いパフォーマンスを維持することができます。

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。