タングステンカーバイドブッシング are widely used in pumps, compressors, turbines, and mechanical seals — where they must handle high pressure, speed, and temperature.

To work reliably, these bushings must maintain their shape, strength, and fit under stress, load, and temperature changes.

If not properly designed or analyzed, they may crack, deform, or seize, leading to equipment failure and costly downtime.

This article explores how stress, mechanical load, and thermal expansion affect tungsten carbide bushings — and how proper analysis ensures long-lasting performance.

Understanding the Mechanical Behavior of Tungsten Carbide

Tungsten carbide (WC) is known for being extremely hard and wear-resistant, but it behaves differently from steel or bronze.

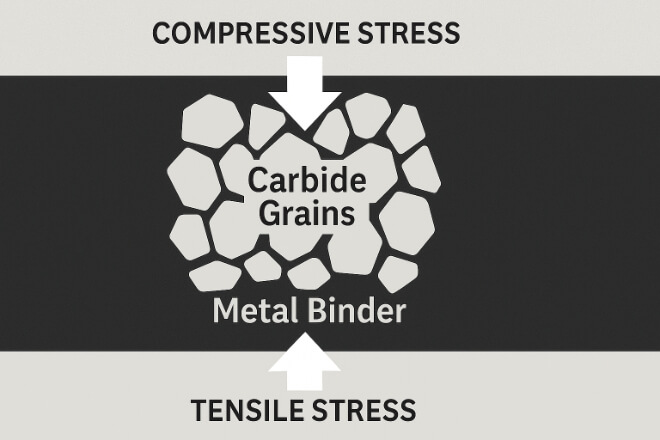

It is a brittle composite material, combining:

Cobalt or Nickel binder – adds some 強靭さ and flexibility.

Because of this structure, WC can handle very high compressive stress, but it is more sensitive to tensile stress or impact.

This difference is key to designing bushings that perform under various mechanical and thermal conditions.

Types of Stress Acting on Tungsten Carbide Bushings

When bushings are installed in rotating or pressurized systems, they are exposed to multiple forms of stress simultaneously.

| Stress Type | 説明 | Typical Source | Possible Effect |

|---|---|---|---|

| Compressive Stress | Force that squeezes the bushing inward. | Shaft pressure, mechanical load. | Safe within limits; WC has high compressive strength (~6,000 MPa). |

| Tensile Stress | Force that pulls the bushing apart. | Improper fit or excessive torque. | Can cause cracking or failure; WC is weak in tension (~700 MPa). |

| Shear Stress | Force acting parallel to the surface. | Rotational friction, misalignment. | Leads to micro-cracking and wear. |

| Thermal Stress | Expansion mismatch due to temperature rise. | Heat from friction or fluid temperature. | Possible cracking or loss of clearance. |

Among these, thermal and tensile stresses are the most critical to control during both manufacturing and operation.

Load Conditions and Their Impact

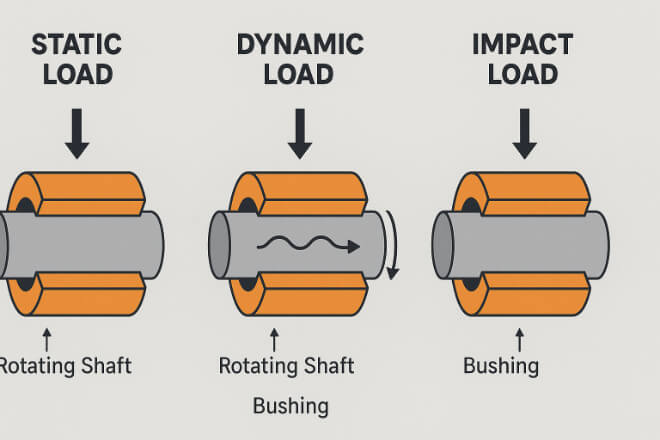

Bushings experience different kinds of mechanical loads during operation.

Understanding these helps engineers design the correct wall thickness, tolerance, and support geometry.

1). Static Load

Constant pressure applied by the shaft or fluid.

Causes elastic deformation that must remain below design limits.

2). Dynamic or Cyclic Load

Occurs in rotating shafts or reciprocating pumps.

Repeated stress can cause fatigue micro-cracks in the carbide matrix.

3). Impact Load

Short bursts of high force (e.g., sudden start-up or cavitation).

Tungsten carbide’s low ductility makes it sensitive to this type.

By using finite element analysis (FEA), designers can model these loads and predict weak points before production.

Thermal Expansion in Tungsten Carbide Bushings

Like any material, tungsten carbide expands when heated. However, its coefficient of thermal expansion (CTE) is much lower than that of steel or other metals.

| 材料 | CTE (×10⁻⁶ / °C) | Thermal Conductivity (W/m·K) | Remarks |

|---|---|---|---|

| Tungsten Carbide (WC-Co) | 4.5–5.5 | 80–100 | Stable under temperature; minimal expansion. |

| ステンレス鋼 | 16–17 | 15–25 | Expands faster; can cause interference fits to tighten. |

| ブロンズ | 17–19 | 40–50 | Poor thermal stability at high temperatures. |

Because of its low expansion, tungsten carbide maintains dimensional stability even under hot conditions, which helps prevent shaft seizure or misalignment.

However, when carbide is fitted into a steel housing, differential expansion can cause stress — which must be compensated through clearance design or interference fit control.

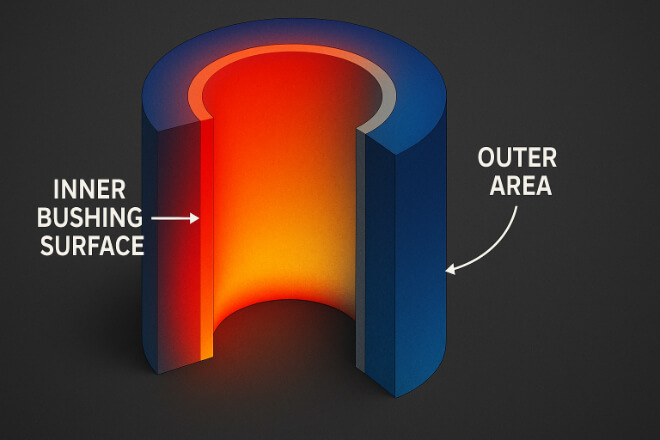

Analyzing Stress from Thermal Gradients

In high-speed pumps or compressors, temperature can vary across the bushing surface.

The inner surface (near the shaft) heats up faster than the outer surface, creating a thermal gradient.

This uneven heating produces internal stress that can lead to:

Cracks along the bore surface.

Dimensional distortion.

Changes in contact pressure and clearance.

To minimize these risks:

Maintain steady coolant flow or lubrication.

Use symmetrical geometries to ensure even heat distribution.

Apply vacuum-sintered carbides with uniform microstructure to handle stress better.

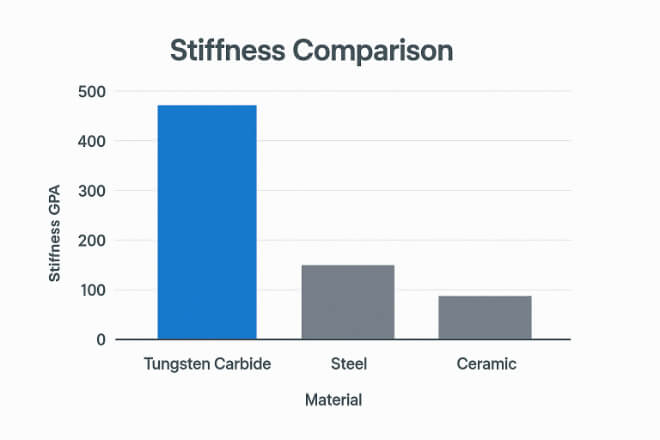

Role of Elastic Modulus and Strength

Tungsten carbide has a very high Young’s modulus (~600 GPa) — nearly three times that of steel.

This means it resists deformation under load but cannot flex much before cracking.

When used as a bushing:

The compressive load is well tolerated.

The tensile and bending stress must be minimized by proper mounting and alignment.

Finite element simulations help determine the optimal wall thickness and fit tolerance that keep stresses within safe limits during operation.

Best Practices for Design and Installation

To ensure tungsten carbide bushings perform safely under stress and temperature variation, engineers should follow these design guidelines:

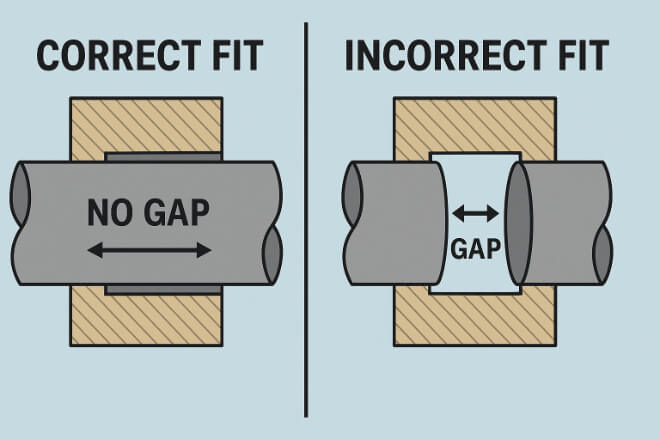

Avoid over-tight interference fits – excessive press fitting may cause tensile cracking.

Match CTEs of mating materials – especially in metal housings.

Use precise surface finishes (Ra ≤ 0.05 µm) to reduce frictional heat.

Apply gradual heating or cooling during assembly and shutdown.

Monitor temperature and vibration in high-speed machinery.

Practical Examples

Submersible pumps: Carbide bushings operate under both pressure and abrasive loads. The analysis ensures no fracture during startup when water temperature rises.

Oil & gas compressors: Rapid temperature changes during shutdown can create internal stress if fits are too tight.

Cryogenic systems: Minimal expansion of tungsten carbide makes it ideal for very low temperatures.

Each case requires balancing mechanical strength, fit clearance, and thermal properties for optimal reliability.

結論

Understanding stress, load, and thermal expansion is essential when designing or selecting tungsten carbide bushings.

These parameters determine:

How the bushing deforms under mechanical pressure.

How it reacts to temperature changes.

How long it will last under real operating conditions.

By using simulation tools and precision manufacturing, companies can design bushings that maintain dimensional accuracy, resist cracking, and perform reliably across demanding environments.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。