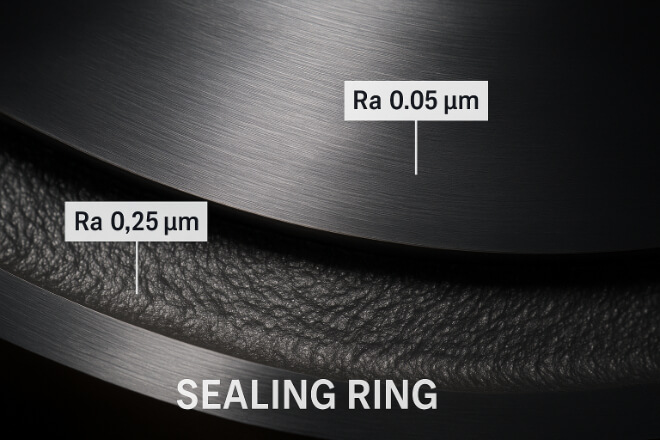

In mechanical seals, the surface topography of sealing rings directly affects leakage control, lubrication retention, and 耐摩耗性.

An Ra value between 0.04–0.05 μm is often specified for high-performance applications, but many decision-makers may wonder what this number truly represents and why it matters.

This article explains Ra 0.04–0.05 μm in simple terms, its impact on sealing performance, and best practices for achieving and maintaining such surfaces.

What Ra 0.04–0.05 μm Represents

Ra (Roughness Average) measures the average height of microscopic peaks and valleys on a surface.

Ra 0.04–0.05 μm means the surface irregularities are less than one-twentieth of a human hair’s diameter.

This level of smoothness is achieved through precision lapping and polishing.

Such finishes are typically found in critical pumps, compressors, and バルブ where even micro-leaks are unacceptable.

Why Surface Topography Matters

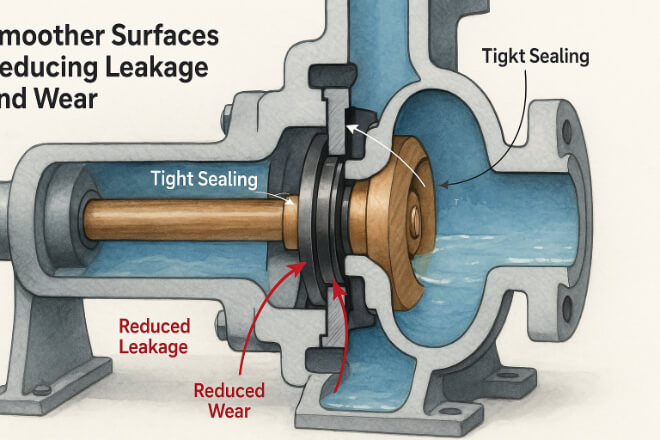

Leakage control: Ultra-smooth surfaces reduce gaps between mating faces.

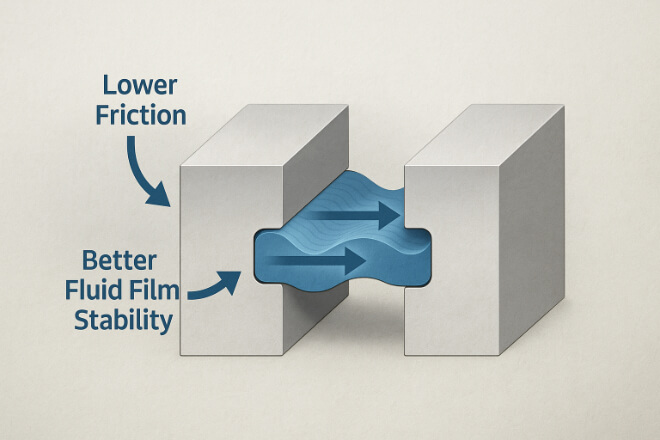

Lubrication stability: Proper topography supports a stable fluid film.

耐摩耗性: Smooth surfaces reduce friction and extend seal life.

Energy efficiency: Less friction means reduced power consumption.

The Relationship Between Ra and Seal Performance

Tighter Sealing: Low Ra values create consistent contact, preventing micro-channels for leakage.

Friction Reduction: Smoother surfaces reduce heat buildup during operation.

Startup Protection: Balanced roughness helps retain lubrication during startup to avoid dry running.

Longevity: Reduced friction and heat prevent premature wear and equipment downtime.

Achieving Ra 0.04–0.05 μm: Lapping and Polishing

1). Lapping

Use cast iron or composite plates with diamond slurry.

Maintain even pressure with conditioning rings.

Monitor flatness frequently with optical tools.

2). Polishing

Switch to fine diamond paste or slurry with grit ≤1 μm.

Apply light pressure and control temperature to prevent warping.

Inspect surface finish with profilometers to verify Ra values.

Verification of Surface Finish

Regular verification ensures surfaces stay within specification:

Profilometer testing: Measures Ra accurately.

Optical flats and monochromatic light: Check flatness and uniformity.

Microscopy: Identifies scratches or contaminants.

Comparison Table: Ra Values and Sealing Quality

| Ra Value (μm) | Surface Description | 典型的なアプリケーション |

|---|---|---|

| 0.04–0.05 | Ultra-smooth, mirror-like | Critical pumps, compressors, cleanrooms |

| 0.1–0.2 | Smooth, high-quality finish | General industrial pumps and valves |

| >0.3 | Moderate roughness | Low-speed, low-pressure systems |

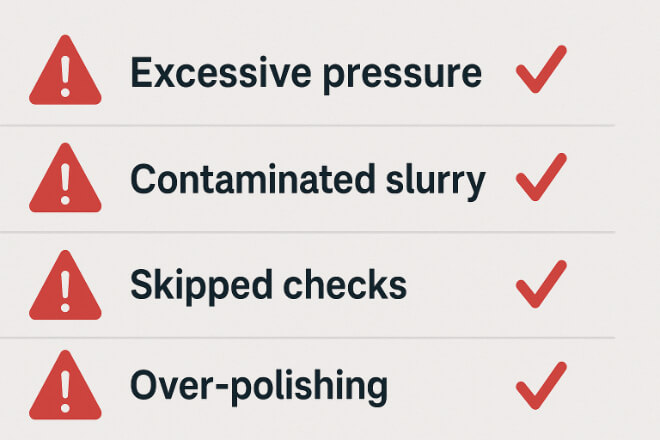

Common Pitfalls When Targeting Ra 0.04–0.05 μm

Excessive pressure during polishing: Can cause distortion or scratches.

Contaminated slurry: Introduces defects on the surface.

Skipping intermediate checks: Leads to uneven finishes.

Over-polishing: May round edges and affect flatness.

業界の事例

Pharmaceutical mixers: Require ultra-smooth surfaces to prevent contamination.

Semiconductor pumps: Demand minimal particle generation.

Marine pumps: Use precise surfaces to maintain lubrication film under variable speeds.

石油・ガス compressors: Need tight seals to prevent hazardous leaks.

Maintenance Practices to Preserve Ra Quality

Regular inspections: Check seal faces for wear or scratches.

Clean environments: Prevent dust or debris contamination.

Controlled storage: Keep rings in dry, clean areas.

Re-polishing: Restore surface finish rather than replacing entire components.

コストとROIの考慮

Initial investment: Precision lapping equipment and diamond abrasives may cost more upfront.

Savings: Reduced leakage and downtime lead to significant operational cost savings.

ROI: Improved sealing performance extends equipment life and lowers maintenance costs.

結論

Ra 0.04–0.05 μm is more than a specification—it’s a key factor in seal reliability, lubrication stability, and energy efficiency.

Decision-makers who understand and maintain this level of surface finish can ensure better equipment performance, longer service life, and lower operational costs.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。