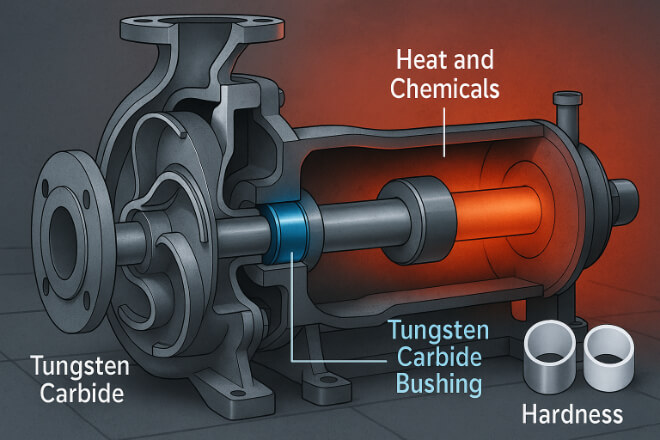

タングステンカーバイドブッシング are known for their exceptional 硬度, 耐摩耗性、そして耐久性。

They are used in demanding industries — from 石油とガス to chemical processing — where components must withstand friction, pressure, and corrosion.

However, what truly defines the performance of a tungsten carbide bushing is not just the tungsten carbide itself, but the binder metal that holds it together — most often cobalt.

The cobalt binder forms the metallic “glue” between the hard tungsten carbide grains, giving the bushing the right mix of 強靭さ and hardness.

In this article, we’ll explore how cobalt binder content affects bushing properties, performance, and applications — and why getting this balance right is key for your process.

What Is a Cobalt Binder?

In tungsten carbide, about 85–95% of the material is made up of WC (tungsten carbide) grains — the hard ceramic particles that resist wear.

The remaining 5–15% is metallic binder, usually cobalt, which binds these grains together during sintering.

This binder phase plays a major role in controlling the mechanical strength, 強靭さ, and resistance to cracking of the final part.

When cobalt content is adjusted, it directly changes how the tungsten carbide bushing behaves in real operating conditions.

How Cobalt Binder Affects Key Properties

The percentage of cobalt binder typically ranges from 4% to 15%, depending on the grade and use case.

The chart below shows how this affects 硬度, 強靭さ、 そして wear resistance.

| Cobalt Binder (%) | 硬度(HRA) | 強靭さ | 耐摩耗性 | 一般的な用途 |

|---|---|---|---|---|

| 4–6% | 91–93 | 低い | 素晴らしい | High wear, low impact environments |

| 7–9% | 89–91 | 中くらい | 良い | General-purpose bushings and tools |

| 10–12% | 87–89 | 高い | 適度 | Impact-prone or high-vibration systems |

| 13–15% | 85–87 | 非常に高い | より低い | Extreme shock or unlubricated applications |

As you can see, higher cobalt content increases toughness but reduces hardness and wear resistance.

Finding the right balance between these properties is essential for reliable operation.

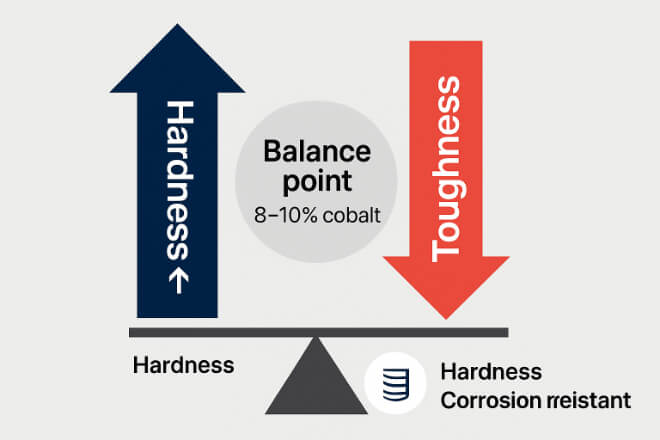

The Hardness–Toughness Trade-Off

This is the key engineering challenge in tungsten carbide design:

When you make a bushing harder, it becomes more brittle. When you make it tougher, it becomes softer.

Low cobalt (4–6%) → very hard, ideal for abrasive and high-speed environments.

Medium cobalt (7–9%) → balanced performance for mixed wear and impact.

High cobalt (10–15%) → better shock absorption but less resistant to abrasion.

| Cobalt Content | Hardness Level | Toughness Level | Recommended Use |

|---|---|---|---|

| Low (4–6%) | 非常に高い | 低い | Fine particles, sand, or slurry wear |

| Medium (7–9%) | バランスの取れた | バランスの取れた | General-purpose pumps and bearings |

| High (10–15%) | 適度 | 非常に高い | High-impact, unlubricated, or dry systems |

The best grade depends on operating speed, lubrication, and medium.

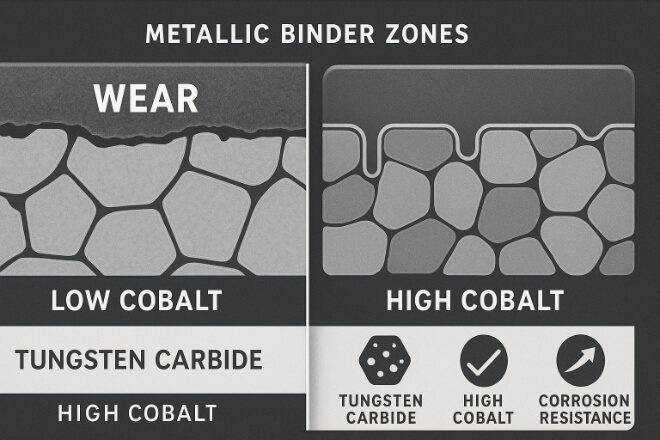

How Cobalt Binder Impacts Wear Resistance

In bushings that operate under friction — such as pump sleeves or compressor bearings — 耐摩耗性 is critical.

Cobalt acts as a “soft phase” between hard tungsten carbide grains. If there is too much cobalt, this metallic phase expands, causing:

Softer surface

Reduced abrasion resistance

Higher wear under sand or slurry

But too little cobalt makes the material brittle and prone to cracking under pressure.

That’s why medium binder levels (around 8–10%) are preferred for most industrial bushings — they provide excellent wear resistance without sacrificing toughness.

Thermal and Corrosion Performance

Cobalt-bonded tungsten carbide performs very well under high temperatures — up to 800°C in air and even higher in inert environments.

However, cobalt is chemically reactive, which makes it more vulnerable to corrosion in:

Acidic fluids

Seawater

Chloride-rich environments

In these cases, nickel-bonded tungsten carbide may be used instead, since nickel offers better 耐腐食性, though with slightly less toughness.

| バインダータイプ | 強靭さ | 耐腐食性 | Ideal Environment |

|---|---|---|---|

| Cobalt | 高い | 適度 | Abrasive and dry wear applications |

| Nickel | 中くらい | 素晴らしい | Chemical, seawater, and corrosive fluids |

For standard pump or compressor bushings, cobalt binders remain the industry standard — offering 強靭性、 shock resistance, and high-load endurance.

Selecting the Right Cobalt Content for Your Application

When selecting タングステンカーバイドブッシング, consider the type of stress your system faces:

| Application Type | Recommended Cobalt (%) | Reason / Key Advantage |

|---|---|---|

| Fine Particle or Slurry Wear | 4–6% | 高い硬度と耐摩耗性 |

| Balanced Wear and Impact | 7–9% | Versatile and reliable |

| High Vibration or Dry Operation | 10–12% | More toughness, prevents fracture |

| Shock or misalignment-prone | 13–15% | Extra ductility and strength |

This ensures the bushing operates efficiently without premature wear or cracking.

Final Verdict

The cobalt binder content in tungsten carbide bushings defines their mechanical personality.

It decides how well the bushing can handle friction, pressure, impact, and corrosion.

Low cobalt → Hard and 耐摩耗性.

Medium cobalt → Balanced and reliable for most systems.

High cobalt → Tough and shock-resistant, but less wear-resistant.

For most applications, 8–10% cobalt provides the best balance between strength and durability.

結論

Cobalt binder is the hidden factor that determines how well tungsten carbide bushings perform.

It connects the hardness of carbide with the toughness of metal, giving your equipment the best of both worlds.

By understanding how cobalt content affects hardness, wear, and toughness, engineers and procurement teams can select the perfect grade for their conditions — improving uptime and reducing maintenance costs.

The right cobalt percentage can make the difference between a bushing that lasts months and one that lasts years.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。