High-speed machining (HSM) is an advanced manufacturing technique that allows companies to achieve higher productivity and precision by operating at faster speeds and feeds.

In this process, タングステンカーバイドチップ play a crucial role, providing the necessary durability, heat resistance, and 耐摩耗性 to maintain cutting performance at high speeds.

In this blog, we’ll explore the importance of tungsten carbide tips in high-speed machining, how they contribute to improving machining efficiency, and why they are the preferred choice for many industries.

What Is High-Speed Machining?

High-speed machining involves running cutting tools at faster speeds and higher feeds than traditional machining methods.

This process increases the efficiency of manufacturing operations by reducing cycle time, improving surface finish, and enhancing material removal rates.

However, it also places more stress on the cutting tools, requiring materials that can withstand high heat and wear while maintaining precision.

1). The Role of Cutting Tools in High-Speed Machining

In high-speed machining, the cutting tool’s ability to handle increased heat and friction is crucial.

Tools must maintain their sharpness and precision to ensure optimal performance.

Tungsten carbide tips are ideal for high-speed operations because of their 硬度, 耐摩耗性, and thermal conductivity.

Why Tungsten Carbide Tips Are Ideal for High-Speed Machining

Tungsten carbide tips offer a number of advantages that make them the go-to choice for high-speed machining.

Their exceptional properties help maintain cutting performance even under challenging conditions.

Tungsten carbide is one of the hardest materials available, making it highly resistant to wear and tear.

During high-speed machining, cutting tools are exposed to intense friction, which can cause rapid wear.

Tungsten carbide tips resist this wear, maintaining their sharpness and effectiveness for longer periods, which reduces the need for frequent tool replacements.

2). Heat Resistance

High-speed machining generates a significant amount of heat. Tungsten carbide has a high melting point, which allows it to maintain its hardness even at elevated temperatures.

This heat resistance is crucial in ensuring that the tips can withstand the stresses of high-speed cutting without degrading or losing their cutting edge.

3). Precision and Stability

Tungsten carbide tips provide high precision, making them ideal for operations that require tight tolerances.

Their stability at high speeds ensures that the tool maintains its shape and does not deform, leading to consistent cuts and improved product quality.

Benefits of Tungsten Carbide Tips in High-Speed Machining

Using tungsten carbide tips in high-speed machining offers several key benefits, making them a preferred choice for industries that rely on precision and efficiency.

1). Increased Material Removal Rate (MRR)

Tungsten carbide tips enable faster cutting speeds, which results in a higher material removal rate.

This increased efficiency reduces production time and enhances throughput, making the manufacturing process more cost-effective.

2). Improved Surface Finish

The precision of tungsten carbide tips ensures a smoother surface finish on the workpiece.

This is especially important in industries like 自動車, 航空宇宙, and medical device manufacturing, where surface quality is critical.

3). Extended Tool Life

The durability of tungsten carbide tips extends their lifespan, which reduces the frequency of tool changes and downtime.

This is a significant advantage in high-speed machining, where tools are subjected to greater stresses.

Less downtime means more continuous production and lower operational costs.

4). Reduced Cutting Force

Because tungsten carbide tips maintain sharpness and stability at high speeds, they reduce the amount of cutting force required.

This reduces the stress on both the tool and the workpiece, preventing damage and improving the efficiency of the machining process.

Optimizing Cutting Parameters for Tungsten Carbide Tips

To get the most out of tungsten carbide tips in high-speed machining, it’s important to optimize cutting parameters such as cutting speed, feed rate, and depth of cut.

These factors impact tool life, machining efficiency, and overall performance.

1). Cutting Speed

タングステンカーバイドチップ are designed to operate at high cutting speeds, but it’s important to balance cutting speed with other parameters.

Too high a cutting speed can lead to excessive heat, causing tool wear or failure.

However, when used correctly, increased cutting speed leads to faster production times and higher material removal rates.

2). Feed Rate

The feed rate, or how fast the workpiece moves into the tool, should also be optimized.

A high feed rate can lead to faster material removal, but if set too high, it can increase cutting forces and lead to tool wear.

Finding the optimal feed rate ensures that the carbide tips work efficiently without compromising their lifespan.

3). Depth of Cut

The depth of cut impacts the amount of material removed in each pass.

For high-speed machining with tungsten carbide tips, a shallower cut is often preferred to reduce heat buildup and tool wear.

However, deeper cuts may be necessary depending on the material being machined.

Applications of Tungsten Carbide Tips in High-Speed Machining

Tungsten carbide tips are used in a wide range of high-speed machining applications.

Their ability to handle high cutting speeds, abrasive materials, and extreme conditions makes them ideal for industries that require precision and efficiency.

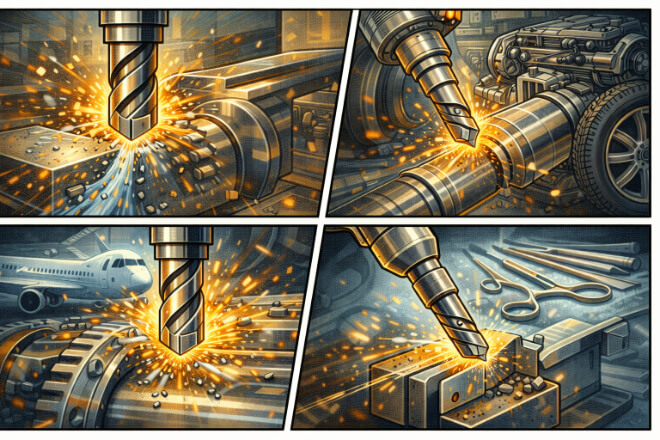

1). Metalworking

In metalworking, tungsten carbide tips are commonly used for cutting, drilling, and milling metal components.

彼らの 耐摩耗性 and heat tolerance allow them to perform well on tough metals like steel and titanium.

2). Automotive and Aerospace

Both the 自動車 そして 航空宇宙 industries require precision parts that must meet tight tolerances.

Tungsten carbide tips are ideal for machining these parts, ensuring high-quality cuts, improved surface finishes, and reduced production times.

3). Medical Device Manufacturing

In medical device manufacturing, tungsten carbide tips are used for high-precision cutting of materials like titanium, stainless steel, and polymers.

Their sharpness and durability ensure the production of intricate parts with smooth surfaces.

結論

Tungsten carbide tips are essential for high-speed machining due to their unmatched hardness, wear resistance, and heat tolerance.

While they come with a higher upfront cost, the long-term benefits in terms of productivity, tool life, and machining efficiency make them a wise investment for manufacturers.

By optimizing cutting parameters and using carbide tips effectively, businesses can maximize the performance of their tools and improve the overall efficiency of their machining processes.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。