In CNC (Computer Numerical Control) machining, tool life is a critical factor in maintaining productivity and minimizing costs.

The longevity of tools directly impacts the efficiency of the manufacturing process, and shorter tool life can lead to increased downtime, higher replacement costs, and more frequent maintenance.

タングステンカーバイドチップ are widely used in CNC machining due to their exceptional durability, 硬度、 そして resistance to wear.

This blog will explore how tungsten carbide tips contribute to increased tool life in CNC machining and why they are an essential component for manufacturers looking to enhance operational efficiency.

1. Understanding the Importance of Tool Life in CNC Machining

Tool life refers to the duration a cutting tool remains effective in performing its intended tasks before it becomes worn or damaged.

In CNC machining, longer tool life is desirable as it reduces the need for frequent tool replacements and maintenance, which can disrupt production schedules.

Longer tool life also results in more consistent results, less downtime, and reduced production costs.

Key Factors Impacting Tool Life:

材料 硬度: The hardness of the material being cut directly affects tool wear. Harder materials tend to wear down tools faster.

切断速度: Higher cutting speeds can increase heat generation, which can lead to tool degradation.

工具の摩耗: Over time, the cutting edge of a tool becomes dull, affecting the quality of the cut and reducing overall machining efficiency.

Optimizing tool life is crucial for CNC machining operations, and tungsten carbide tips are a proven solution to enhance tool durability and performance.

2. Why Tungsten Carbide Tips are Ideal for CNC Machining

Tungsten carbide is a composite material that combines tungsten and carbon, creating a highly durable and wear-resistant material.

It is widely used in CNC machining due to its exceptional hardness, resistance to heat, and ability to maintain sharp edges even under heavy cutting conditions.

Key Benefits of Tungsten Carbide Tips:

硬度: Tungsten carbide tips are among the hardest materials available, making them ideal for cutting tough materials like stainless steel, titanium, and other hard alloys.

耐摩耗性: The exceptional wear resistance of tungsten carbide reduces the frequency of tool replacement, making it highly cost-effective in the long run.

耐熱性: Tungsten carbide maintains its hardness at high temperatures, reducing the risk of tool deformation or failure during high-speed machining operations.

These properties make tungsten carbide tips ideal for CNC machining applications, where precision and tool longevity are crucial for optimizing productivity.

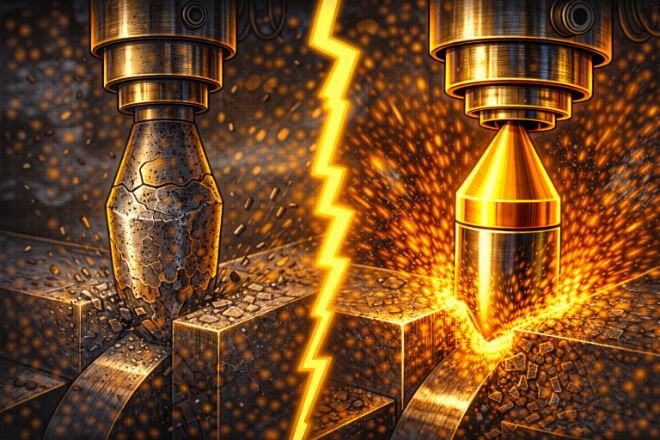

3. Reducing Tool Wear with Tungsten Carbide Tips

One of the primary reasons tungsten carbide tips are used in CNC machining is their ability to significantly reduce tool wear.

The wear on cutting tools occurs due to the constant friction, heat, and mechanical forces during the cutting process.

Tungsten carbide tips, due to their 硬度 そして 耐摩耗性, are much more durable than other materials and maintain their cutting edge longer, even under demanding conditions.

Key Ways Tungsten Carbide Reduces Tool Wear:

Low Friction: Tungsten carbide’s smooth surface reduces friction during cutting, leading to less heat buildup and slower wear of the tool.

Resistance to Abrasive Forces: The high hardness of tungsten carbide allows it to resist abrasive materials that would quickly wear down other cutting tools.

熱安定性: Tungsten carbide’s ability to withstand high temperatures prevents the cutting edge from softening or becoming deformed during high-speed machining.

By using tungsten carbide tips, manufacturers can extend the life of their CNC tools, reducing the need for frequent replacements and improving machining efficiency.

4. Maintaining Cutting Precision for Longer Periods

As tools wear down, their ability to maintain cutting precision diminishes. This can lead to less accurate cuts, lower quality products, and increased scrap.

タングステンカーバイドチップ help maintain cutting precision over a longer period, allowing for high-quality finishes and more consistent machining results.

Key Benefits for Precision:

Maintaining Sharpness: Tungsten carbide tips retain their sharpness for longer periods, allowing for cleaner cuts with fewer inaccuracies.

Consistent Results: With less tool wear, CNC machines can produce consistent results across long production runs, improving product quality and reducing defects.

The ability to maintain cutting precision for longer periods allows CNC machining operations to meet tight tolerances and improve overall production quality.

5. Reducing Maintenance and Downtime

CNC machining requires regular maintenance to ensure that machines are functioning properly.

Frequent tool replacements due to wear can lead to increased downtime and maintenance costs.

Tungsten carbide tips, with their long lifespan, help reduce the frequency of tool changes and minimize downtime.

How Tungsten Carbide Tips Help Reduce Downtime:

ツール交換の削減: Tungsten carbide tips last longer than conventional tools, reducing the need for frequent replacements and machine stoppages.

メンテナンスコストの削減: With fewer replacements and less tool wear, manufacturers can reduce the costs associated with maintaining CNC machines, as well as the labor costs for changing tools.

By reducing downtime and maintenance requirements, tungsten carbide tips contribute to smoother, more efficient production runs.

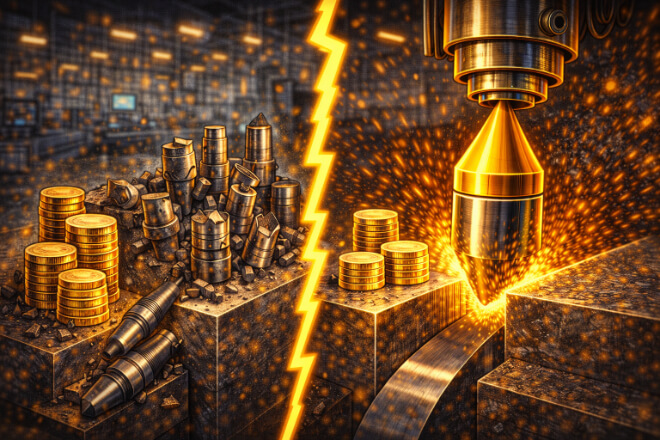

6. Improved Cost-Effectiveness Over Time

While tungsten carbide tips may have a higher upfront cost compared to other materials, the long-term cost savings far outweigh the initial investment.

Due to their extended tool life, reduced wear, and lower maintenance costs, tungsten carbide tips are highly cost-effective in CNC machining operations.

Long-Term Cost Benefits:

Reduced Tool Replacement Costs: Fewer replacements mean lower costs for tool procurement and fewer interruptions to the production process.

生産性の向上: By reducing tool wear and extending tool life, manufacturers can increase their production efficiency and throughput, leading to more output for the same input.

Lower Scrap Rates: Tungsten carbide tips help maintain cutting precision, reducing the number of defective parts produced and lowering scrap rates.

In the long run, the cost savings associated with tungsten carbide tips make them a worthwhile investment for CNC machining operations looking to optimize their cost structure.

7. Applications of Tungsten Carbide Tips in CNC Machining

Tungsten carbide tips are used in a variety of CNC machining applications, from cutting and drilling to milling and turning.

Their ability to handle high speeds and tough materials makes them suitable for industries such as aerospace, automotive, medical device manufacturing, and metalworking.

Common Applications:

精密フライス加工: Tungsten carbide tips are ideal for precision milling operations, where tool longevity and sharpness are crucial for maintaining tight tolerances.

掘削: In drilling operations, tungsten carbide tips provide excellent 耐摩耗性, even when drilling through tough materials like steel and titanium.

Turning and Grinding: Tungsten carbide tips can be used in turning and grinding operations, where high cutting speeds and accurate material removal are essential.

Regardless of the specific CNC machining application, tungsten carbide tips contribute to improved performance and extended tool life across various industries.

結論

Tungsten carbide tips play a vital role in increasing tool life in CNC machining.

Their hardness, wear resistance, and heat stability help reduce tool wear, maintain cutting precision, and reduce downtime, all while improving productivity and cost-effectiveness.

By choosing tungsten carbide tips, manufacturers can extend the life of their CNC tools, optimize their machining processes, and reduce long-term costs.

With these benefits, tungsten carbide tips have become an essential component for businesses aiming to enhance their operational efficiency and competitiveness in the manufacturing industry.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。