In modern mechanical systems, friction control plays a key role in efficiency and durability. Whether in pumps, compressors, or turbines, every moving part relies on bushings or bearings to reduce wear and maintain stability.

Among many materials used, タングステンカーバイドブッシング stand out for their exceptional tribological performance — the science of friction, wear, and lubrication.

Understanding the tribology and friction behavior of tungsten carbide is not just for materials scientists.

For engineering managers and procurement teams, this knowledge helps in choosing bushings that can handle extreme pressure, temperature, and corrosive media — while reducing downtime and maintenance costs.

This article explains what tribology means, how it relates to tungsten carbide, and why this material offers unmatched wear and friction control across industries.

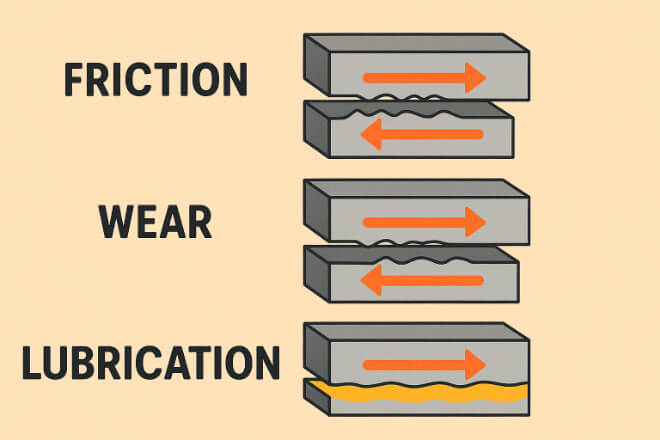

What Is Tribology?

Tribology is the study of how surfaces interact when in motion. It focuses on three main areas:

Friction – the resistance to motion when two surfaces slide.

Wear – the gradual removal or deformation of material.

Lubrication – the process of minimizing direct surface contact.

In the case of tungsten carbide bushings, tribology determines:

How efficiently the bushing supports a rotating shaft.

How fast wear occurs under dry or lubricated conditions.

How much heat and energy are lost due to friction.

When properly designed and polished, carbide bushings can operate with minimal friction and very low wear rates, even under poor lubrication.

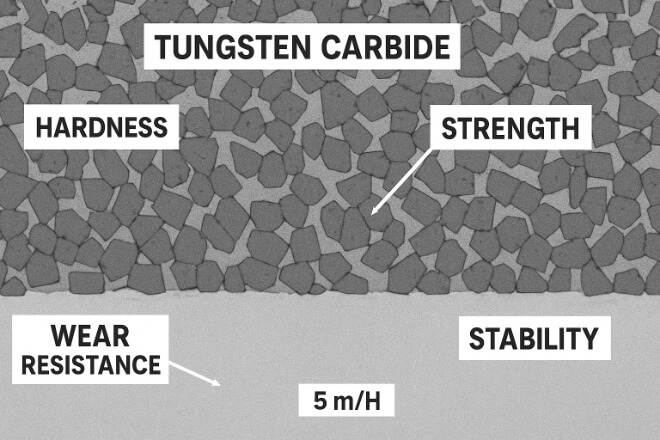

Why Tungsten Carbide Excels in Tribology

Tungsten carbide’s superior tribological performance comes from its unique combination of hardness, 強靭さ, and chemical stability.

It resists surface deformation, maintains its smoothness under pressure, and forms stable contact with the mating material (often steel, ceramic, or another carbide).

Key advantages include:

高い 硬度 (up to 1800–2000 HV) → resists abrasive wear.

高い圧縮強度 → withstands heavy radial loads.

優れた熱伝導性 → dissipates frictional heat effectively.

Chemical inertness → resists oxidation and corrosion during sliding contact.

Together, these factors make tungsten carbide bushings ideal for high-speed, high-load, and high-temperature environments.

Types of Friction in Tungsten Carbide Bushings

The behavior of tungsten carbide under motion depends on the type of friction acting on it.

There are three major forms:

| Friction Type | 説明 | Tribological Implication | Example Application |

|---|---|---|---|

| Dry Friction | Occurs without lubrication between two solid surfaces. | High wear; requires high hardness and surface polish. | Seals and bushings in dry gas compressors. |

| Boundary Friction | Thin lubrication film present; surfaces occasionally touch. | Moderate wear; material pair compatibility is key. | Oil-lubricated bearings in gear pumps. |

| Fluid Film Friction | A full film of lubricant separates surfaces completely. | Very low wear; surface finish and roundness critical. | Hydrodynamic pump bushings, sleeve bearings. |

Tungsten carbide performs well under all three, but its best results come under boundary or fluid film lubrication, where the combination of smooth finish and hardness minimizes friction.

Surface Finish and Its Role in Friction Behavior

The surface finish of a bushing directly affects its tribological performance.

A smoother surface reduces the real contact area between moving parts, leading to lower friction and wear.

Typical finishes for tungsten carbide bushings:

Ground finish (Ra ≈ 0.2 µm): For general industrial use.

Lapped finish (Ra ≈ 0.05 µm): For precision and fluid applications.

Mirror-polished (Ra ≤ 0.03 µm): For sealing faces and high-speed rotations.

When combined with a matching shaft surface, a mirror-polished tungsten carbide bushing can reduce friction coefficient (µ) to as low as 0.05–0.08 under lubricated conditions.

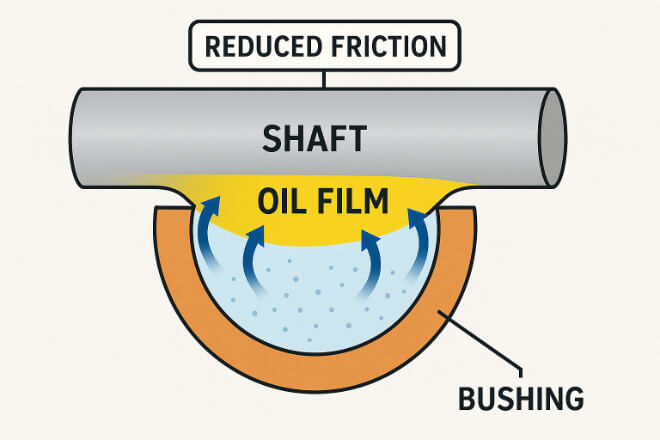

Effect of Lubrication on Tribological Performance

Lubrication forms a protective layer between two sliding surfaces, reducing contact and frictional heat.

For tungsten carbide bushings, choosing the right lubricant depends on operating conditions:

Oil-based lubricants: For high-speed, low-load systems.

Grease or solid lubricants: For slower, intermittent movements.

Water or process fluids: In pumps handling slurries or chemicals.

Even in poor lubrication or dry conditions, tungsten carbide resists galling and maintains integrity, unlike softer metals.

Material Pairing and Compatibility

Tribological performance depends not only on the carbide itself but also on the counterface material — the surface that slides against the bushing.

| Material Pair | Relative Friction (µ) | 摩耗率 | Comments |

|---|---|---|---|

| WC-Co vs Stainless Steel | 0.10–0.15 | 低い | Stable sliding, low corrosion risk. |

| WC-Co vs WC-Co | 0.05–0.10 | 非常に低い | Excellent for sealing and precision fits. |

| WC-Ni vs Ceramic | 0.08–0.12 | 非常に低い | Ideal for chemical or corrosive media. |

Proper material pairing minimizes adhesive wear and avoids galling or metal transfer between surfaces.

Tribological Testing Methods

To ensure carbide bushings meet friction and wear expectations, manufacturers conduct laboratory tribology tests.

Common test setups include:

Pin-on-disk test: Measures friction coefficient and wear rate.

Ball-on-flat test: Simulates point contact in dynamic motion.

Block-on-ring test: Reproduces sliding under load and lubrication.

These tests allow engineers to predict real-world performance, such as:

Coefficient of friction (µ)

Wear volume loss (mm³)

Surface roughness after test

Modern suppliers provide tribology reports that help buyers compare grades and select materials suitable for their operating conditions.

Applications Where Tribology Matters Most

Industries that rely heavily on tungsten carbide’s friction performance include:

Centrifugal and submersible pumps (reduced shaft wear under pressure)

Oil and gas compressors (minimal friction at high RPM)

Mechanical seals and valves (low leakage and 耐摩耗性)

Chemical process equipment (stable performance under corrosive media)

By selecting the right grade and finish, engineers can extend equipment life by 30–50% compared to traditional metal bushings.

How to Optimize Friction Performance

Decision-makers can improve tribological results by focusing on four key factors:

Select the correct carbide grade (fine-grain for wear, coarse-grain for shock).

Ensure proper surface finish (Ra ≤ 0.05 µm).

Pair materials correctly (WC-Co with steel or WC-Ni with ceramics).

Monitor lubrication quality and avoid contamination.

Regular inspection and polishing during maintenance also help preserve low-friction performance.

結論

Tribology defines how well a tungsten carbide bushing performs in motion.

Its microstructure, hardness, and surface finish all work together to control friction, wear, and heat generation.

For engineering leaders, understanding these interactions helps in:

Selecting longer-lasting components,

Reducing unplanned downtime, and

Improving total system efficiency.

By partnering with suppliers who understand carbide tribology, companies can achieve smoother operations and better ROI on critical machinery.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。