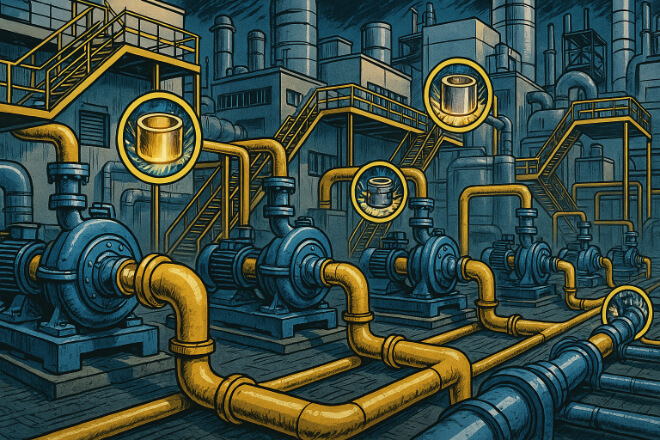

Pulp and paper plants rely on process pumps to move fiber slurry, chemicals, and treated water through different stages of production.

These pumps operate under tough conditions, with high solids, chemicals, and continuous wear.

To improve pump reliability and reduce downtime, many mills are now switching to タングステンカーバイドブッシング.

These bushings provide long service life, strong 耐摩耗性, and better stability under abrasive and corrosive process conditions.

Challenges in Pulp and Paper Pumping Systems

Pulp and paper processes involve a complex mix of fibers, chemicals, and water. This mixture creates severe wear and corrosion inside pumps.

Key challenges include:

High abrasiveness from wood fibers, sand, and fillers

Chemical attack from bleaching agents and cleaning chemicals

Corrosion from acidic or alkaline environments

High temperature in certain stages

Continuous 24/7 operation, increasing wear

Vibration and misalignment from changing load conditions

Because of these factors, pumps require bushings that can perform reliably under heavy mechanical and chemical stress.

Why Tungsten Carbide Bushings Are Ideal for Pulp and Paper Mills

Tungsten carbide offers a unique combination of 硬度, 強靭さ、 そして 耐腐食性 that makes it ideal for pulp and paper process pumps.

Main advantages:

Excellent wear resistance against fiber slurry and sand

Strong corrosion resistance, especially in bleaching stages

Stable performance under vibration and shaft movement

Longer operating cycles between overhauls

Low friction, reducing energy consumption

Better protection for pump shafts

These advantages directly help mills lower downtime and maintenance costs.

Understanding the Pumping Stages Where TC Bushings Are Used

タングステンカーバイドブッシング are used in many key pump types throughout the mill.

Common pump applications:

Stock pumps

Slurry pumps

Chemical dosing pumps

Bleaching stage circulation pumps

Screening pumps

White water pumps

Reject handling pumps

These pumps handle different fluids, but all experience abrasion, corrosion, or both.

Tungsten Carbide Grades for Pulp and Paper Applications

Different parts of the pulp and paper process require different grades of tungsten carbide depending on the mix of abrasiveness and corrosion.

Recommended Grade Table

| 学年 | バインダー | 利点 | 最適な用途 |

|---|---|---|---|

| WC-6Co | Cobalt | High hardness, strong wear resistance | Fiber-rich slurry and sand-loaded stages |

| WC-12Co | Cobalt | Toughness with good wear resistance | General process pumps |

| WC-Ni | Nickel | Strong corrosion resistance | Bleaching and chemical dosing pumps |

Common Wear and Failure Modes in Pulp and Paper Pumps

Even with durable materials, pulp and paper environments can cause damage if conditions become extreme.

1). Typical failure modes include:

Abrasive wear from wood fibers and fillers

Chemical corrosion in bleaching stages

Binder leaching when exposed to strong chemicals

Chipping due to misalignment or shock loads

Erosion from fast-flowing slurry

Scaling from mineral deposits

2). Failure Mode Table

| Failure Mode | Primary Cause | Severity | Solution |

|---|---|---|---|

| Abrasive Wear | Fibers, sand, fillers | 高い | Use harder WC-Co grades |

| 腐食 | Bleach or alkali chemicals | 高い | Switch to WC-Ni |

| Chipping | Shock loads, misalignment | 中くらい | Improve alignment and support |

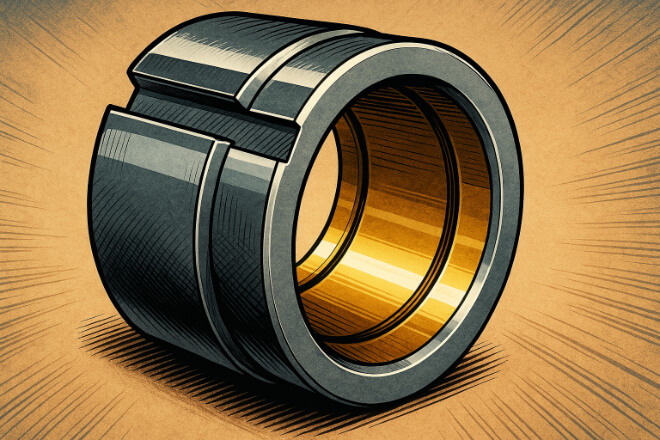

Design Requirements for Bushings in Pulp and Paper Pumps

The design of tungsten carbide bushings determines their performance under pulp and paper conditions.

Key design features

高い-密度 HIP sintering to resist chemical attack

Polished bore surface to reduce friction

Thick-walled design for vibration stability

Corrosion-resistant binder selection

低い 気孔率 to prevent chemical penetration

Precision roundness to maintain shaft stability

Proper clearance fit to avoid overheating

These design choices help achieve longer service intervals in demanding process stages.

Maintenance Tips for Long Bushing Life

To maximize performance, mills should follow a smart maintenance plan.

Recommended actions

Inspect alignment during each shutdown

Monitor vibration and noise levels

Check for early abrasion signs

Flush pumps regularly to remove fiber buildup

Replace bushings before wear becomes excessive

Monitor chemical concentration in bleaching processes

Preventive maintenance reduces unplanned downtime and protects pump shafts from damage.

Selecting a Reliable Supplier for Mill Applications

The supplier must understand both mechanical and chemical needs of pulp and paper operations.

Supplier qualifications

Experience with pulp and paper applications

Ability to produce WC-Ni and WC-Co grades

HIP sintering capability

OEM customization support

Fast delivery and stable supply chain

A qualified supplier helps mills reduce pump failures and maintenance frequency.

結論

Pulp and paper process pumps face heavy abrasion and strong chemical exposure.

Tungsten carbide bushings offer long service life, strong wear resistance, and stable pump performance across all stages of the mill.

By choosing the right grade and design—and by working with a qualified supplier—operators can significantly reduce downtime and improve plant efficiency.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。