The oilfield and petrochemical industries run some of the most demanding systems in the world.

Pumps, compressors, valves, and drilling equipment must work under high pressure, heat, and corrosive fluids.

A failure in sealing systems can lead to downtime, safety risks, and financial loss. This is why many companies choose tungsten carbide seal rings.

This article explains how タングステンカーバイドシールリング perform in oilfield and petrochemical applications, their unique properties, and why they are the best option for long-term reliability and cost savings.

Why Seal Rings Matter in Oilfield and Petrochemical Equipment

Seal rings are critical in protecting equipment against:

Leakage of 石油、ガス、 or chemicals

Erosion from abrasive particles

高温による熱応力

急激な圧力変化による機械的衝撃

A strong, durable seal material ensures safety, compliance, and efficiency in these harsh environments.

炭化タングステンシールリングの特性

Tungsten carbide is a material created by combining tungsten and carbon, bonded with cobalt or nickel. Its main properties include:

過激 硬度 – Prevents wear from friction and abrasives.

High compressive strength – Withstands heavy pressure loads.

Thermal stability – Works reliably in hot oil and gas systems.

耐腐食性 – Resists hydrocarbons, seawater, and chemicals.

Long service life – Reduces replacement frequency.

These features make tungsten carbide the preferred sealing material in drilling rigs, refineries, and petrochemical plants.

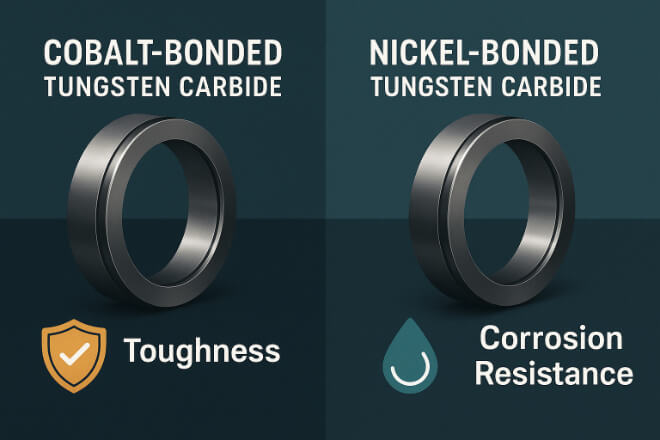

コバルト結合タングステンカーバイドとニッケル結合タングステンカーバイド

Binder choice affects performance:

1)コバルト結合炭化タングステン

2)ニッケル結合タングステンカーバイド

Excellent resistance to corrosive chemicals.

Best for refineries and petrochemical plants.

コバルト結合よりも若干強度が劣ります。

Decision-makers must match the grade to the specific operating environment.

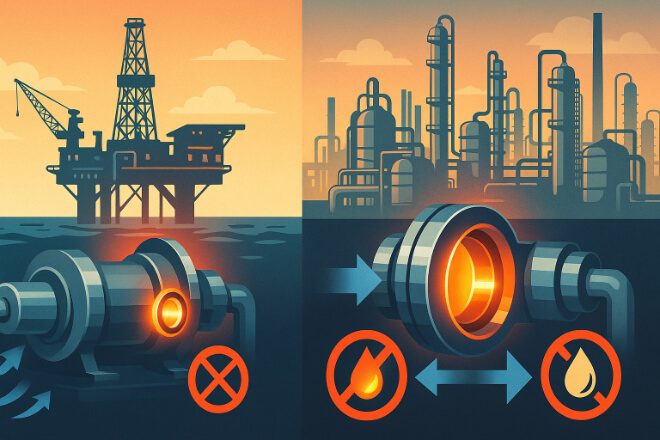

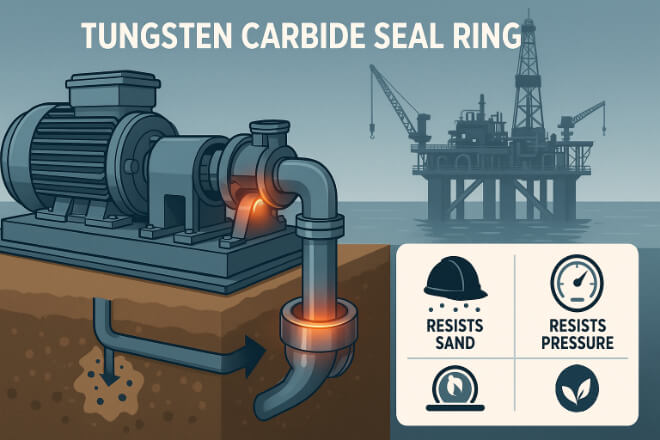

Performance in Oilfield Applications

In oilfield operations, seal rings face:

High-pressure crude 石油とガス

Sand and abrasive particles in drilling fluids

Extreme temperature changes

Protect pumps and compressors from wear.

Prevent leakage that could cause safety issues.

Extend service life in drilling and production systems.

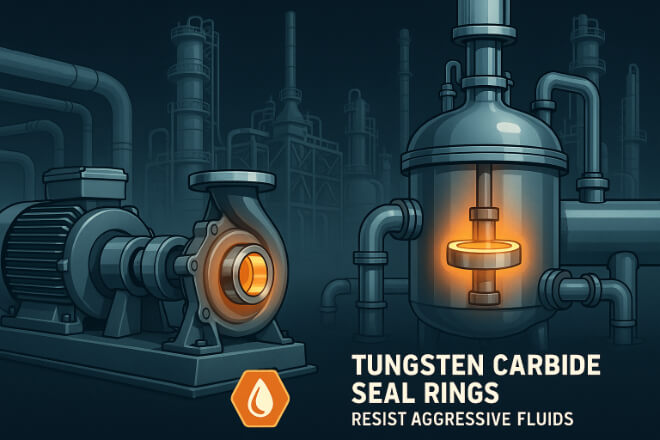

Performance in Petrochemical Applications

In petrochemical plants, seals face aggressive chemical exposure. Tungsten carbide seal rings:

Provide resistance against solvents, acids, and alkalis.

Work reliably in refinery pumps and chemical reactors.

Reduce downtime by lasting longer under corrosive conditions.

This makes them essential in facilities where chemical resistance is critical.

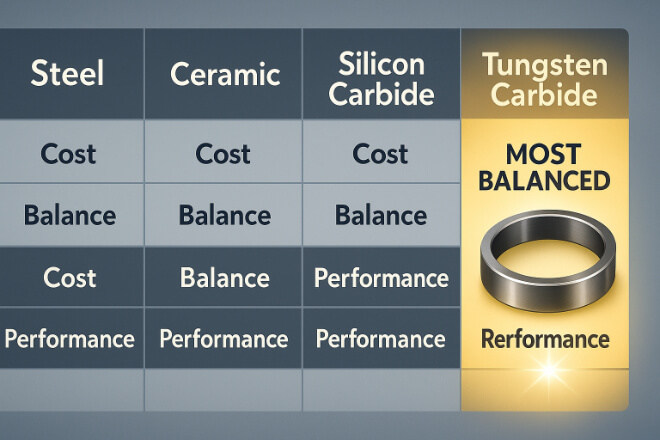

他のシール材との比較

Steel seals – Cheap but corrode quickly in oil and chemicals.

Ceramic seals – Chemically resistant but brittle under shock.

Silicon carbide – Strong against chemicals but less tough under impact.

Tungsten carbide – Best balance of strength, 強靭さ, and chemical resistance.

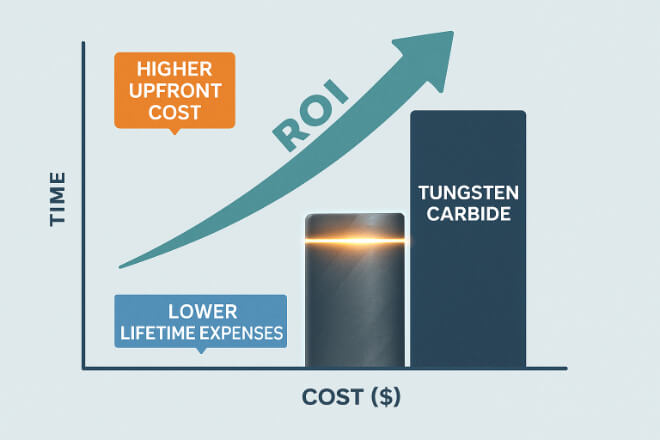

コスト vs 長期的な価値

Although tungsten carbide seal rings have a higher initial cost, their life cycle benefits outweigh the price:

交換品の減少 → スペアパーツのコストを削減します。

ダウンタイムの短縮 → 生産性の向上。

Longer pump life → Reduced equipment damage.

より良いROI → 意思決定者にとって強力な財務上の根拠。

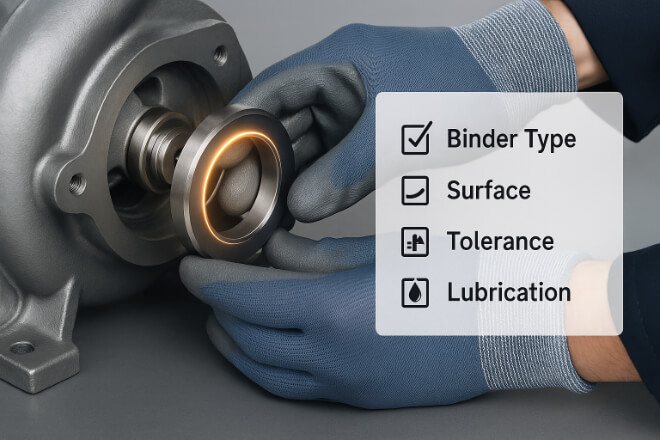

タングステンカーバイドシールリングの使用に関するベストプラクティス

To ensure maximum performance in oilfield and petrochemical systems:

Choose the right grade → 腐食にはニッケル、衝撃にはコバルト。

慎重に取り付けてください → Avoid scratches that weaken chemical resistance.

定期的に検査する → 摩耗や腐食の兆候を早期に発見します。

潤滑を維持する → Reduces heat and friction damage.

持続可能性とリサイクル

Tungsten carbide seal rings are recyclable. Many suppliers reclaim used rings and process them into new products.

This reduces waste and supports environmental goals, which is increasingly important in oil and petrochemical industries.

意思決定者にとっての重要なポイント

Tungsten carbide seal rings are best for oilfield and petrochemical equipment.

They resist wear, pressure, heat, and corrosion.

Cobalt-bonded grades suit heavy loads and shock.

Nickel-bonded grades suit chemical-rich environments.

Higher upfront cost is offset by longer service life and fewer failures.

結論

For oilfield and petrochemical applications, tungsten carbide seal rings are the most reliable choice. They handle harsh conditions, corrosive fluids, and heavy loads better than most alternatives.

For decision-makers, investing in tungsten carbide seal rings means safer operations, less downtime, and stronger long-term value.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。