Asphalt milling machines are essential tools in road construction and maintenance, as they are designed to remove layers of asphalt and concrete quickly and efficiently. The performance of these machines depends heavily on the quality of the cutting tools used.

タングステンカーバイドチップ are increasingly being used in asphalt milling machines due to their exceptional durability, 耐摩耗性, and high performance under demanding conditions.

In this blog, we will explore the key performance benefits of using tungsten carbide tips in asphalt milling machines and how they can improve productivity, reduce costs, and extend the lifespan of the equipment.

Why Tungsten Carbide Tips Are Ideal for Asphalt Milling Machines

Tungsten carbide is renowned for its hardness and wear resistance, making it an ideal material for use in asphalt milling machines.

When cutting through asphalt and concrete, the tools are exposed to high wear and intense friction.

Tungsten carbide tips can withstand these harsh conditions, improving both tool life and performance.

1). 硬度 and Durability

Tungsten carbide is one of the hardest materials available, making it highly resistant to wear and deformation.

This is particularly important in asphalt milling, where tools face constant abrasion from hard surfaces.

The hardness of carbide tips allows them to maintain their sharpness and cutting ability for much longer periods compared to traditional materials, reducing the need for frequent tool replacements.

2). Excellent 耐摩耗性

Asphalt milling involves continuous contact between the cutting tools and the road surface, resulting in significant wear.

Tungsten carbide tips excel in this environment due to their wear resistance, ensuring they perform efficiently even under heavy use.

This durability minimizes downtime caused by tool replacements, keeping the milling machines operational for longer periods.

3). Heat Resistance

The milling process generates significant friction, which can cause heat buildup in the tools.

Tungsten carbide has excellent heat resistance, meaning the tips maintain their hardness and cutting performance even in high-temperature conditions.

This heat resistance is crucial for maintaining consistent performance in high-speed milling operations.

Performance Benefits of Tungsten Carbide Tips in Asphalt Milling Machines

Using tungsten carbide tips in asphalt milling machines brings several performance advantages, from improved cutting precision to reduced operational costs.

1). Improved Cutting Efficiency

Tungsten carbide tips help asphalt milling machines achieve greater cutting efficiency.

Their sharpness and durability allow the machines to remove material quickly and smoothly, reducing the time required to complete each milling job.

This leads to faster project completion and improved overall productivity.

2). Longer Tool Life

Tungsten carbide’s wear resistance extends the lifespan of milling tools, reducing the need for frequent replacements.

Longer tool life translates to lower maintenance costs and less downtime for milling machines. This is especially beneficial in large-scale projects where time and budget are critical.

3). Consistent Performance

Tungsten carbide tips provide consistent performance over time. Unlike other materials that may lose their sharpness or effectiveness as they wear, carbide tips maintain their cutting edge throughout their service life.

This consistency ensures that the milling machine delivers high-quality results in every operation, reducing the need for rework or repairs.

4). Reduced Vibration and Smoother Operation

The rigidity and toughness of tungsten carbide tips also help reduce vibration during milling operations.

Reduced vibration leads to smoother cuts and less stress on the equipment, contributing to the overall stability and longevity of the asphalt milling machine.

How Tungsten Carbide Tips Help Lower Operational Costs

One of the main benefits of using tungsten carbide tips in asphalt milling machines is the potential for lowering operational costs.

The durability and performance of carbide tips offer long-term savings in several areas:

1). Fewer Tool Replacements

の 硬度 そして 耐摩耗性 of tungsten carbide tips significantly reduce the frequency of tool replacements.

Unlike softer materials that may require frequent changes, carbide tips last much longer, reducing the cost of buying and storing spare parts.

2). Lower Maintenance Costs

Milling machines that use tungsten carbide tips experience less wear and tear, which results in lower maintenance costs.

The extended life of the tips means fewer repairs and less downtime, helping to keep the equipment running smoothly and efficiently.

3). Increased Productivity

With longer tool life and reduced downtime, the overall productivity of the milling machine increases.

The ability to complete milling projects faster and more efficiently contributes to lower labor costs and quicker project turnaround times.

4). Energy Efficiency

Tungsten carbide tips reduce the need for excessive force during cutting.

This leads to lower energy consumption during milling operations, resulting in cost savings on fuel or electricity, especially in large-scale projects that require continuous operation.

Choosing the Right Tungsten Carbide Tips for Asphalt Milling Machines

Selecting the right タングステンカーバイドチップ is essential for maximizing the performance and longevity of asphalt milling machines. Factors to consider include:

1). Carbide Grade

The grade of tungsten carbide used in the tips affects their performance in different conditions.

For milling hard asphalt or concrete, a higher grade of tungsten carbide is recommended to ensure optimal wear resistance and cutting performance.

2). Tool Geometry

The design of the tungsten carbide tips, such as the shape and angle of the cutting edge, plays a significant role in their performance.

The right geometry ensures that the milling machine operates efficiently, providing smoother cuts and better material removal.

3). Coatings and Surface Treatments

Some tungsten carbide tips come with special coatings or surface treatments that enhance their performance in harsh conditions.

These coatings can improve wear resistance and reduce friction, further extending the life of the tips and improving cutting efficiency.

Applications of Tungsten Carbide Tips in Road Construction and Maintenance

Tungsten carbide tips are widely used in asphalt milling machines for various road construction and maintenance tasks.

Their ability to withstand harsh conditions makes them perfect for these applications:

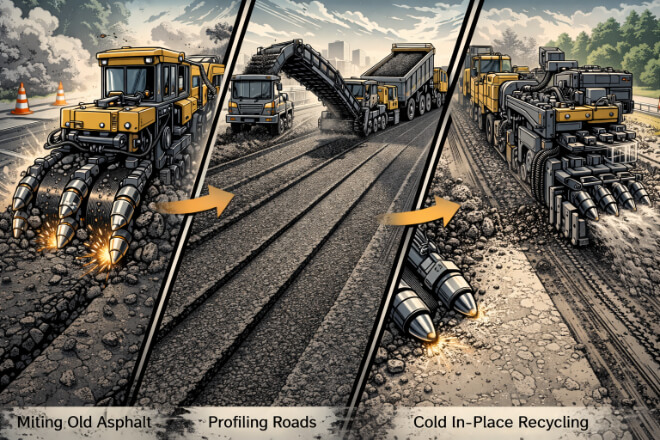

1). Milling Old Asphalt

Asphalt milling machines with tungsten carbide tips are used to remove old asphalt layers in road resurfacing projects.

The durability of carbide tips ensures that the milling machine can cut through tough, hardened asphalt with minimal wear.

2). Profiling Roads

Milling machines are also used to profile roads, creating smooth surfaces that meet design specifications.

Tungsten carbide tips ensure that these machines maintain accuracy and precision during the profiling process, ensuring high-quality results.

3). Cold In-Place Recycling

Cold in-place recycling (CIR) is a method used to rehabilitate old roads by milling and reusing the existing asphalt.

Tungsten carbide tips help improve the efficiency of this process by providing longer tool life and better performance when cutting through thick asphalt layers.

結論

Tungsten carbide tips are essential for improving the performance and efficiency of asphalt milling machines.

Their hardness, wear resistance, and heat tolerance allow them to excel in demanding road construction and maintenance applications.

By using tungsten carbide tips, companies can extend tool life, reduce downtime, improve cutting efficiency, and lower operational costs.

Whether for resurfacing roads, profiling surfaces, or recycling old asphalt, tungsten carbide tips provide reliable and cost-effective solutions for the road construction industry.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。