When working with tougher materials, choosing the right cutting tool is critical to ensuring both performance and longevity. Two popular options in industrial applications are タングステンカーバイドチップ and steel tips.

Both materials have their advantages, but understanding which one is best suited for specific tasks is essential for optimizing efficiency.

This blog will compare tungsten carbide tips with steel tips, focusing on their properties, performance, and suitability for tougher materials.

What are Tungsten Carbide Tips?

Tungsten carbide is a composite material made from tungsten and carbon, offering exceptional 硬度 そして 耐摩耗性.

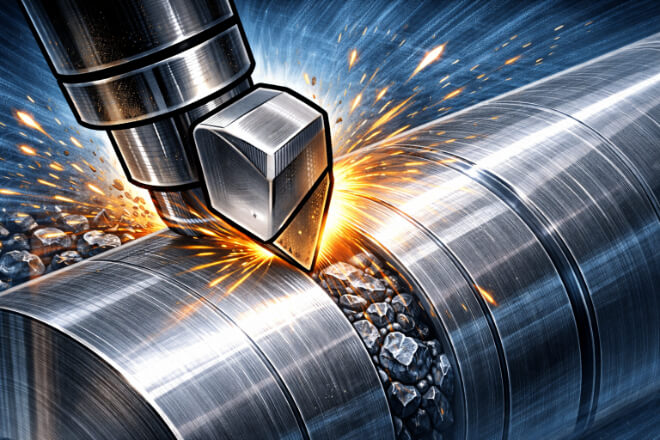

It is often used in industries that require high-performance cutting tools, such as 採掘, construction, and manufacturing.

Tungsten carbide tips are known for their ability to withstand extreme pressure, high temperatures, and abrasive environments.

These tips are often used in applications where other materials would wear out quickly, such as cutting through tough metals, rocks, and concrete.

The strength and durability of tungsten carbide make it an ideal choice for these heavy-duty tasks.

What are Steel Tips?

Steel is a versatile and commonly used material in cutting tools. It is generally more affordable than tungsten carbide but tends to have lower 硬度 そして 耐摩耗性.

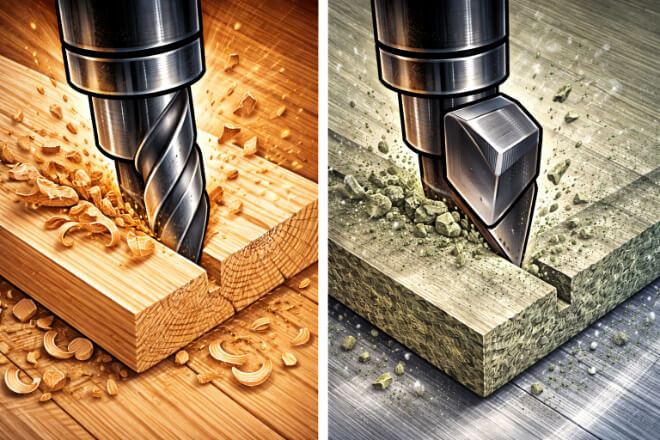

Steel tips are used in a variety of applications, from woodworking to machining, and are suitable for cutting softer materials like aluminum, plastics, and some steels.

Steel tips are often favored for their 強靭さ and flexibility. While they may not perform as well as tungsten carbide in high-stress environments, they still offer reliable performance in less demanding tasks and are often easier to sharpen.

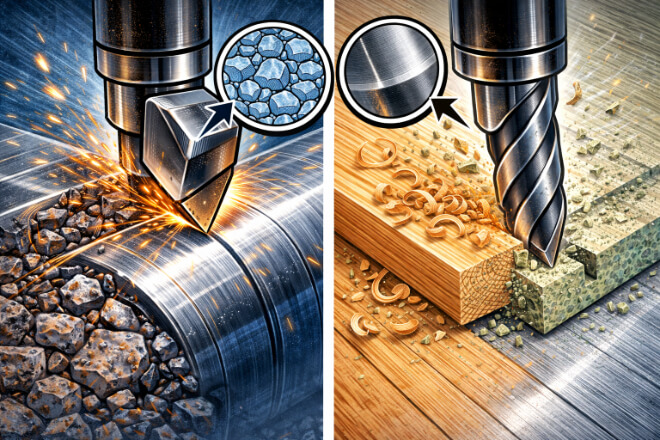

Hardness and Wear Resistance: A Key Comparison

One of the most significant factors in selecting cutting tips for tougher materials is the hardness and wear resistance of the material.

タングステンカーバイド:

With a 硬度 rating of 9 on the Mohs scale, tungsten carbide is much harder than steel, which typically ranges between 4 and 5 on the Mohs scale.

This means tungsten carbide tips retain their sharpness for longer, making them more suitable for hard and abrasive materials.

鋼鉄:

Steel tips are softer compared to tungsten carbide. They are more prone to wear and lose their edge faster when used on harder materials.

However, steel tips can still provide satisfactory performance for softer materials or in applications where flexibility is more important than hardness.

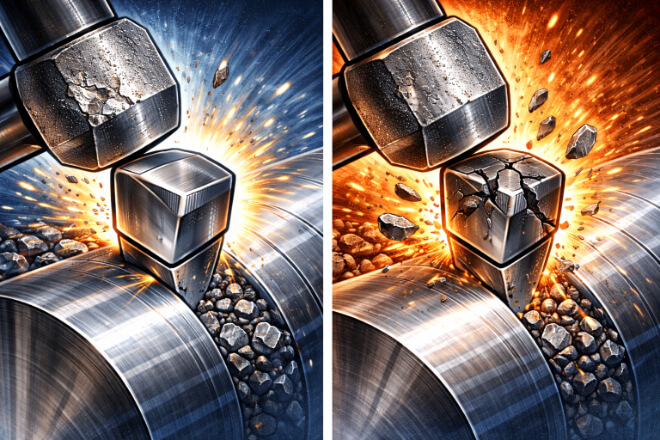

Impact Resistance: Steel vs Tungsten Carbide

While tungsten carbide excels in hardness, steel offers better 強靭さ due to its ability to absorb impact without breaking.

Steel tips are less brittle and can withstand heavy shocks or impacts without chipping or cracking.

This makes steel a better choice in environments where high-impact forces are common, such as in certain machining or forming operations.

On the other hand, tungsten carbide tips, while incredibly hard, are more brittle and may crack or chip when subjected to high-impact forces.

For applications that involve extreme pressure or sudden impacts, steel may be the more reliable option.

Cost and Durability: Which Material is More Cost-Effective?

タングステンカーバイド:

Tungsten carbide tips are more expensive than steel tips due to the complex manufacturing process and the high cost of raw materials.

However, their exceptional 硬度 そして 耐摩耗性 often result in longer tool life, making them a more cost-effective option in the long run, especially when working with tough or abrasive materials.

鋼鉄:

Steel tips are more affordable upfront, but they may wear out faster when cutting tougher materials, leading to more frequent tool replacements.

For operations that don’t involve abrasive or tough materials, steel tips can be a cost-effective solution, but they may not offer the same longevity as tungsten carbide.

Applications of Tungsten Carbide Tips vs Steel Tips

タングステンカーバイドチップ:

Ideal for cutting through hard and abrasive materials like stainless steel, cast iron, concrete, and rocks.

They are commonly used in 採掘, drilling, and heavy-duty machining applications where toughness and durability are essential.

Steel Tips:

Better suited for lighter applications like woodworking, plastic machining, and cutting softer metals.

Steel tips are frequently used in general machining and cutting tasks, especially when cost and flexibility are more important than cutting through harder materials.

Maintenance and Sharpening: How Do They Compare?

タングステンカーバイドチップ:

Tungsten carbide is incredibly durable, but it is challenging to sharpen.

Specialized tools and techniques are required to restore the cutting edge of タングステンカーバイドチップ, which may increase maintenance costs.

However, due to their long lifespan, tungsten carbide tips typically require less frequent sharpening.

Steel Tips:

Steel tips are easier to sharpen compared to tungsten carbide. They can be honed using traditional grinding or sharpening techniques.

However, since steel wears down faster, they may need to be sharpened more frequently, especially when used on tough materials.

結論

Choosing between tungsten carbide tips and steel tips depends on the application. Tungsten carbide tips offer superior hardness and wear resistance, making them ideal for tougher, abrasive materials.

However, they come at a higher cost and may be more brittle under impact. Steel tips, while more affordable and tougher under impact, are better suited for softer materials.

Ultimately, the choice depends on the specific requirements of the job, balancing performance, cost, and durability.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。