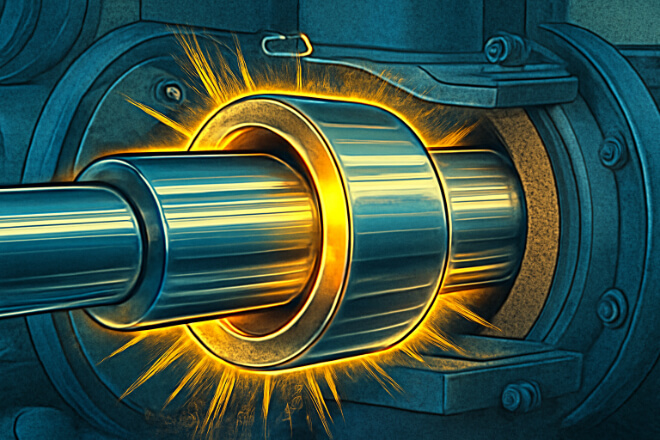

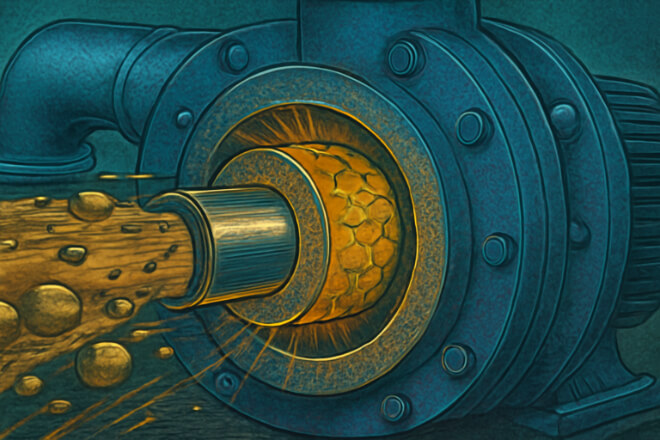

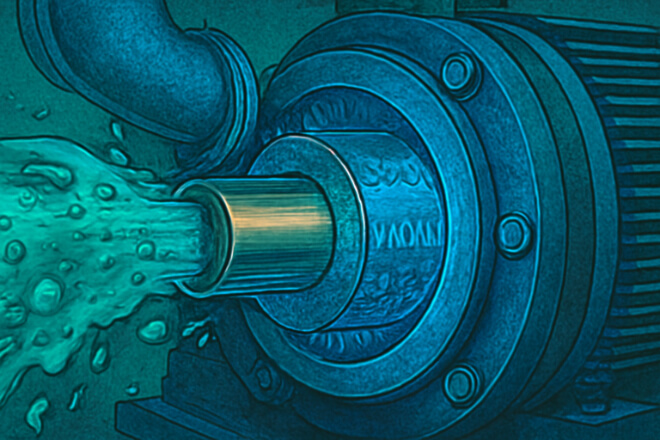

次のような業界では 採掘, 石油とガス, and chemical processing, pumps are subjected to harsh conditions, including abrasive solids, high pressure, and aggressive fluids.

タングステンカーバイドブッシング are often used to protect pump shafts and bearings in these demanding environments.

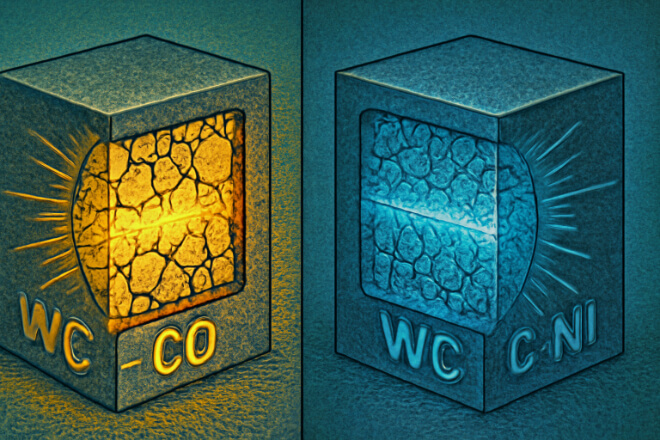

However, the choice of binder in tungsten carbide, particularly WC-Co (cobalt binder) and WC-Ni (nickel binder), plays a critical role in determining the performance and longevity of these bushings.

In this blog, we will compare WC-Co and WC-Ni tungsten carbide bushings to help you decide which binder is best suited for your fluid application.

What Is Tungsten Carbide and Why Is It Used in Pumps?

Tungsten carbide is a highly durable material known for its 硬度 そして 耐摩耗性.

It is composed of tungsten and carbon, and it is typically combined with a binder material (such as cobalt or nickel) to form a composite that provides additional strength and resilience.

Key benefits of tungsten carbide bushings include:

高い 耐摩耗性: Tungsten carbide can withstand heavy abrasion, making it ideal for applications with solid particles in the fluid.

耐腐食性: Tungsten carbide’s dense structure helps prevent chemical attack from aggressive fluids.

High temperature stability: Tungsten carbide can withstand extreme temperatures without losing its structural integrity.

These properties make tungsten carbide bushings particularly useful in pumps that handle abrasive, corrosive, or high-temperature fluids.

The Role of Binders in Tungsten Carbide Bushings

The binder in tungsten carbide bushings plays a critical role in determining their overall properties, including 耐腐食性, 強靭さ、 そして 耐摩耗性.

The most common binders used are cobalt (Co) and nickel (Ni). Both binders provide different performance characteristics, which can make one more suitable than the other depending on the application.

WC-Co (Cobalt Binder) Tungsten Carbide Bushings

1). What is WC-Co?

WC-Co refers to tungsten carbide that is combined with a cobalt binder.

The cobalt binder provides 強靭さ and helps hold the tungsten carbide grains together, making it more resilient under certain conditions.

2). Key benefits of WC-Co bushings:

高い 耐摩耗性: WC-Co bushings are extremely durable and perform well in applications with abrasive particles like sand, silt, or slurry.

Toughness: The cobalt binder adds toughness to the bushing, making it more resistant to mechanical shock and impact.

Ideal for high-impact environments: WC-Co bushings excel in applications where there is significant vibration or sudden shock loads.

3). Best for:

Applications where abrasion is the primary concern, such as mining and dredging.

High-pressure pumps with abrasive slurry or solid particles.

WC-Ni (Nickel Binder) Tungsten Carbide Bushings

1). What is WC-Ni?

WC-Ni is tungsten carbide combined with a nickel binder.

Nickel has a superior resistance to corrosion and is often used in environments where the bushing is exposed to harsh chemicals or saline solutions.

2). Key benefits of WC-Ni bushings:

優れた 耐腐食性: WC-Ni is highly resistant to corrosive environments, especially in acidic or saline fluids.

High chemical stability: The nickel binder resists chemical leaching and degradation, ensuring longevity in harsh environments.

Less prone to binder leaching: The nickel binder helps prevent the bushing from breaking down when exposed to aggressive chemicals, making it ideal for chemical processing applications.

3). Best for:

Applications involving aggressive chemicals or corrosive fluids, such as in the chemical processing, 石油とガス, or seawater handling industries.

Pumps exposed to salts, acids, or alkalis.

WC-Co vs WC-Ni: Which Binder is Right for Your Fluid?

Choosing the right binder for your application depends on the nature of the fluid your pump is handling.

Let’s compare the two binders in terms of their suitability for different fluid types.

1). Binder Comparison Table

| バインダータイプ | 耐摩耗性 | 耐腐食性 | Temperature Stability | 最適な用途 |

|---|---|---|---|---|

| WC-Co | 非常に高い | 中くらい | 高い | Abrasive environments (mining, dredging) |

| WC-Ni | 高い | 非常に高い | 高い | Corrosive fluids (chemicals, seawater) |

2). Which binder should you choose?

Choose WC-Co if your pump is handling abrasive materials like sand, slurry, or solid particles. It’s ideal for mining or dredging applications where mechanical wear is a primary concern.

Choose WC-Ni if your pump is exposed to corrosive or acidic fluids, such as in chemical processing, 石油とガス, or seawater handling. Its superior 耐腐食性 makes it the best choice for handling chemicals, acids, and salts.

Key Considerations When Choosing Tungsten Carbide Bushings

When selecting tungsten carbide bushings for your application, it’s important to consider the following factors:

Fluid composition: Understand the chemicals, solids, and gases the pump will handle.

Temperature range: Choose the binder that can withstand the maximum operating temperature.

Wear conditions: If the application involves abrasive particles, WC-Co might be the better choice.

Corrosive environment: For highly corrosive fluids, WC-Ni offers better protection.

By carefully considering these factors, you can ensure that the bushings you choose will provide the best performance and longevity.

Maintenance and Inspection Tips for Tungsten Carbide Bushings

Regular maintenance and inspection are critical to ensuring the longevity of tungsten carbide bushings. Here are a few best practices:

Maintenance tips:

Monitor wear: Check for signs of abrasion, corrosion, or cracking during regular inspections.

Ensure alignment: Proper alignment of the pump shaft is critical to avoiding excess wear on the bushings.

Use proper lubrication: Ensure the bushings are adequately lubricated to reduce friction and prevent premature wear.

Replace bushings on time: Tungsten carbide bushings have a long lifespan, but they should be replaced before they reach critical wear levels to maintain pump performance.

By following these maintenance tips, you can extend the service life of your bushings and avoid costly downtime.

結論

Choosing the right binder for your tungsten carbide bushings is crucial to the performance and longevity of pumps in demanding environments.

WC-Co is ideal for abrasive environments, while WC-Ni offers superior corrosion resistance for applications involving aggressive fluids.

By understanding your fluid’s characteristics and selecting the appropriate binder, you can ensure that your pumps run efficiently and reliably.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。