今日の急速に変化する製造業の世界では、切削工具は強度、精度、そして耐久性が求められます。 タングステンカーバイド切削工具 お入りください。

これらのツールはほぼすべての業界で使用されています。自動車, 航空宇宙, 工事, 石油・ガス、 さらに、最も硬い材料も簡単に切断できるため、さらに優れています。

機械加工の初心者や、単に工業用ツールに興味がある場合、この初心者向けガイドは、タングステンカーバイド切削工具について知っておく必要のあるすべてのことを理解するのに役立ちます。

これらは何なのか、どのように作られるのか、何が特別なのか、そして実際の生活ではどのように使用されるのかについて説明します。

1. タングステンカーバイドとは何ですか?

タングステンは、2 つの要素を組み合わせて作られた超硬質材料です。

タングステン (W): 強度と高い融点を持つ重金属。

炭素 (C): タングステンと結合して強力な化合物を形成する非金属。

これら 2 つの元素を混合して加熱すると、炭化タングステン (WC) と呼ばれる固体が形成されます。

この素材は鋼鉄の2~3倍の硬さがあり、ダイヤモンドとほぼ同等の硬さがあります。

そのため、切削工具、ドリルビット、金型などによく使われています。 耐摩耗部品.

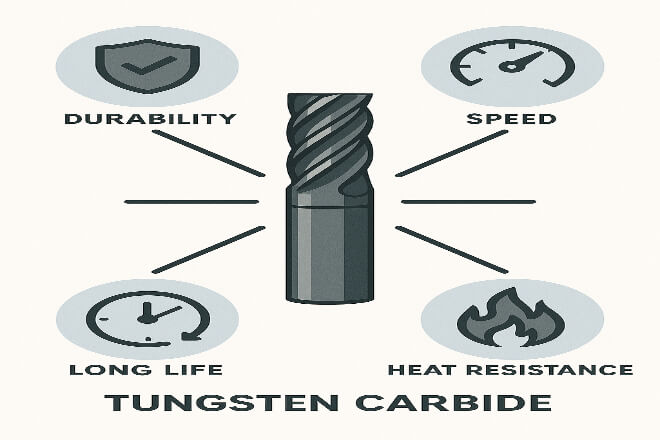

タングステンカーバイドとは:

非常に硬い(モース硬度約9)

非常に密度が高い(鋼鉄より重い)

耐熱性(高速切断に対応)

長持ちし、耐摩耗性に優れています

これらの機能により、摩耗することなく硬い材料を何度も切断、成形、または穴あけする必要があるツールに最適です。

2. 炭化タングステン切削工具とは何ですか?

タングステンカーバイド切削工具は、タングステンカーバイドで作られた刃先を持つ工具です。

これらの刃は、硬い金属や研磨材に使用した場合でも、長期間鋭いままです。

主なタイプは 2 つあります。

超硬工具: 完全に炭化タングステンから作られています。

超硬チップ工具: スチール製の本体とタングステン カーバイドのチップで作られています (コストは低いですが、高性能です)。

一般的な炭化タングステン切削工具の種類には以下のものがあります。

| ツールタイプ | 使用事例 |

|---|---|

| ドリルビット | 金属や石などの硬い材料の穴あけ |

| エンドミル | 金属部品のフライス加工、輪郭加工、スロット加工 |

| 挿入物 | CNCマシン用の交換可能な切削チップ |

| 丸鋸 | 木材、プラスチック、金属、複合材の切断 |

| バーズ | 表面の研削、バリ取り、成形 |

| リーマー | ドリル穴の仕上げとサイズ調整 |

これらのツールは、手動加工と自動 CNC マシンの両方で使用され、速度、精度、生産性の向上に役立ちます。

3. 炭化タングステン工具の主な利点

なぜタングステンカーバイド工具はこれほど広く使われているのでしょうか?主な理由は次のとおりです。

1). 優れた硬度

タングステンカーバイドは、入手可能な工具材料の中で最も硬いものの一つです。高速度鋼(HSS)などの従来の材料よりもはるかに長く切れ味を保ちます。

2). 高い切断速度

超硬工具をより高速で稼働させることができるため、生産速度が向上します。これは特に大量生産において重要です。

3). 長い工具寿命

超硬工具は過酷な条件下でも摩耗しにくいため、工具交換時間を短縮し、全体的な生産コストを削減できます。

4)耐熱性

タングステンは HSS ツールよりもはるかに高い温度に耐えられるため、ツールの損傷を軽減し、切削中の安定性を高めます。

5). 優れた表面仕上げ

ツールは鋭いままなので、ワークピースの表面が滑らかできれいになり、余分な研磨や研削の必要性が減ります。

6.) 強靭な素材でも優れた性能を発揮

超硬工具は、硬化鋼、チタン、鋳鉄、セラミック、さらにはコンクリートまでも切断できます。

4. タングステンカーバイド工具はどこで使用されますか?

炭化タングステン切削工具は幅広い業界で使用されています。主な用途をいくつか見てみましょう。

1). 航空宇宙産業

飛行機やロケットには、チタンやニッケル合金などの丈夫な素材で作られた部品が使われています。

これらの材料を切断するには、切れ味を失わずに加工できる工具が必要です。この分野において、超硬工具は精度と安全性を確保するために不可欠です。

2). 自動車産業

エンジン ブロックからトランスミッション部品まで、多くの車両部品はタングステン カーバイド工具を使用して機械加工されています。

高精度の金型の作成、サイクル時間の短縮、部品の品質向上に役立ちます。

3). 石油・ガス産業

この業界は、研磨性の岩石、高圧、腐食性の環境を扱います。

超硬工具は過酷な条件に耐えられるため、掘削ビット、摩耗部品、バルブ部品に使用されます。

4). 建設・鉱業

コンクリート、花崗岩、または硬い土を切るには、丈夫で長持ちする工具が必要です。

超硬合金製の鋸やドリルは、道路建設から地下採掘まであらゆる用途に使用されています。

5). 金属加工および一般機械加工

機械工場では、旋削、フライス加工、穴あけ、ねじ切りに超硬工具が標準的に使用されています。

鋼鉄、アルミニウム、真鍮、プラスチックのいずれであっても、超硬工具は機械工が速度と精度を維持するのに役立ちます。

6). 医療機器製造

超硬合金製の高精度工具は、インプラント、骨ドリル、外科用器具の製造に使用されます。

カーバイドの耐久性と精度により、安全で無菌的な結果が保証されます。

5. 炭化タングステン工具はどのように作られるのですか?

超硬工具の製造プロセスは技術的ですが、興味深いものです。

ステップ1:粉末の混合

タングステンと炭素の粉末は、強度を高めるためにコバルトなどの結合剤と一緒に混合されることが多いです。

ステップ2:押す

粉末は金型(「ダイ」と呼ばれる)を使用して形状に圧縮され、「グリーンボディ」が形成されます。

ステップ3:焼結

成形体は真空または水素雰囲気中で 1,400 ℃ 以上に加熱され、固体の硬い部品になります。

ステップ4:研磨と仕上げ

工具を正確な仕様に成形するために、特殊なダイヤモンド砥石が使用されます。超硬合金は非常に硬いため、ダイヤモンドだけが効果的に切削することができます。

ステップ5:オプションのコーティング

一部の工具は、耐熱性と耐摩耗性を向上させるために、TiN (窒化チタン) や AlTiN (アルミニウムチタン窒化物) などの材料でコーティングされています。

ステップ6:品質テスト

各ツールは、使用が承認される前に、硬度、バランス、真直度、鋭さがテストされます。

カスタマイズまたは OEM 超硬工具の製造については、Retop はお客様のニーズにぴったり合うカスタマイズされたソリューションを提供します。

7. 炭化タングステンと高速度鋼(HSS)

| 特徴 | タングステンカーバイド | 高速度鋼(HSS) |

|---|---|---|

| 硬度 | 非常に高い(最大9) | 中(約7) |

| 工具寿命 | 長持ちする | 寿命が短くなる |

| 切断速度 | 速い | もっとゆっくり |

| 耐熱性 | 素晴らしい | 適度 |

| 料金 | 初期費用が高い | 初期費用を抑える |

| 最適な使用方法 | 重切削加工 | 軽作業またはDIY作業 |

超硬工具は大量生産や硬い材料に適しています。HSS工具は小規模な作業やそれほど硬くない材料に適しています。

8. 超硬工具に関するよくある質問

1). 超硬工具は安全に使用できますか?

はい。正しく使用し、適切な機械設定で作業すれば、超硬工具は非常に安全です。必ず保護具を着用し、機械の安全に関する指示に従ってください。

2)超硬工具は再研磨できますか?

はい、ダイヤモンド研削装置を使用して専門家が超硬工具を再研磨することができます。

3)超硬工具は脆いですか?

超硬合金は硬いですが脆く、落としたり、機械の設定を間違えたりすると破損する可能性があります。そのため、適切な送り速度を使用し、急激な衝撃を避けることが重要です。

4)どのように保管すればいいですか?

超硬工具は保護箱に入れて、湿気や他の工具との接触を避けて保管してください。これにより、欠けや腐食を防ぐことができます。

最後に

炭化タングステン切削工具は、現代の機械加工および製造において最も重要な工具の一つです。その特徴は以下のとおりです。

- 他のほとんどの工具材料よりも硬い

高速かつ正確な切断のために設計

高温・高圧に耐えられる

あらゆる主要産業で使用されている

長寿命のため長期的には費用対効果が高い

機械加工の世界に初めて足を踏み入れる場合は、超硬工具から始めると、速度、精度、全体的な生産品質を向上させることができます。

プレミアムカーバイドツール、業界サポート、カスタマイズオプションについては、 再トップ 高性能な切断ソリューションをワンストップでご提供します。