Chemical plants operate in environments where pumps, mixers, compressors, and rotating equipment must handle highly corrosive fluids.

These conditions require components that can survive both chemical attack and mechanical wear.

For this reason, many chemical plants choose タングステンカーバイドブッシング as their first option for shaft support and protection.

This article explains why tungsten carbide performs so well, which grades are best, and what decision-makers should look for when selecting bushings for corrosive media.

Why Corrosive Media Require Special Bushing Materials

Chemical processing involves acids, alkalis, solvents, chlorides, and aggressive mixtures that can destroy standard metallic bushings.

Bronze, steel, and even stainless steel can corrode quickly when exposed to these fluids.

Key problems with standard materials

Rapid corrosion that weakens the bushing

Pitting that traps chemicals and increases wear

Surface swelling that affects clearance and increases heat

Short service life, especially in pumps running 24/7

Higher maintenance cost due to frequent replacements

Tungsten carbide bushings solve these problems by providing both 耐腐食性 and extreme hardness, a combination rare in metallic materials.

Chemical Resistance Properties of Tungsten Carbide

Tungsten carbide is a composite material made of WC grains and a metal binder. Its corrosion resistance depends mainly on the binder type.

1). Why tungsten carbide is corrosion-resistant

WC grains are chemically stable

Nickel binders resist most acids and alkalis

The dense structure prevents fluid penetration

低い 気孔率 reduces chemical attack

高い 硬度 protects against erosive-corrosive wear

2). Types of Corrosive Media Where TC Performs Well

Hydrochloric acid (HCl)

Sulfuric acid (H₂SO₄)

Seawater and brine

Chlorinated fluids

Caustic soda (NaOH)

Solvents

Wastewater with chemicals

Below is a comparison table showing typical corrosion behavior.

3). Corrosion Resistance Comparison Table

| 材料 | 耐腐食性 | 耐摩耗性 | Best Application |

|---|---|---|---|

| ブロンズ | 低い | 低い | Non-corrosive fluids |

| ステンレス鋼 | 中くらい | 中くらい | Light chemical exposure |

| WC-Co | Medium–High | 非常に高い | Abrasive and semi-corrosive fluids |

| WC-Ni | 非常に高い | 非常に高い | Highly corrosive chemical media |

Choosing the Best Tungsten Carbide Grade for Chemical Plants

Chemical plants typically specify two main tungsten carbide types depending on media and working conditions.

1). WC-Ni (Nickel Binder): The Best for Corrosive Media

Resists acid and chloride attack

Low cobalt leaching

Very low corrosion rate

Ideal for seawater, acidic wastewater, and strong chemicals

WC-Ni is the top choice for chemical pumps, mixers, and reactors.

2). WC-Co (Cobalt Binder): For Mixed Abrasive and Chemical Conditions

より強く 強靭さ

Better for abrasive fluids

Suitable for slurry with chemicals

Not ideal for strong acids

3). Which grade is best for what condition?

| Operating Condition | Recommended Grade | Reason |

|---|---|---|

| Strong acids / chlorides | WC-Ni | Best corrosion resistance |

| Mixed abrasion + chemicals | WC-6Co | 高い耐摩耗性 |

| Sea water and brine | WC-Ni | Strong chloride resistance |

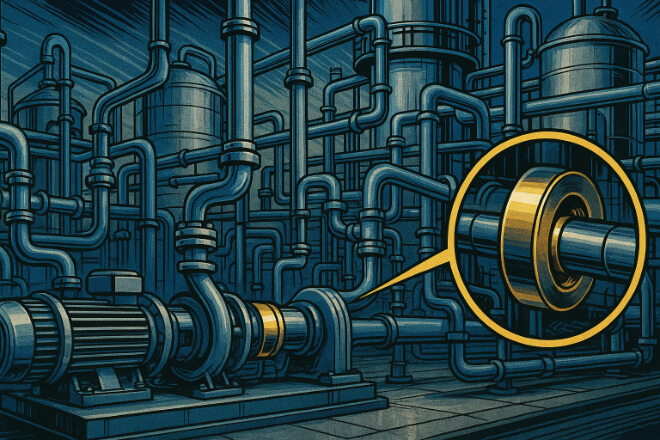

Performance Benefits in Chemical Pumps

Chemical pumps rely heavily on shaft support and bearing stability. Tungsten carbide bushings improve system reliability in several ways.

Major performance advantages

Reduced shaft wear

Lower vibration

Better alignment stability

Improved pump efficiency

Longer running cycles

Less downtime due to bushing failure

Lower lifetime maintenance cost

Chemical companies often calculate ROI, and タングステンカーバイドブッシング consistently provide better value over time.

Applications in Chemical Plants

Tungsten carbide bushings are used in various rotating equipment that must handle corrosive fluid streams.

1). Common equipment types

化学プロセスポンプ

Magnetic drive pumps

Agitators and mixers

Reactor circulation pumps

Seawater intake pumps

Acid-handling pumps

High-RPM dosing pumps

2). Common media handled

Hydrochloric acid

Sulfuric acid

Chlorinated solvents

Wastewater with chemicals

Sodium hydroxide

Brines and seawater

Wherever metal corrosion is a risk, tungsten carbide becomes the preferred material.

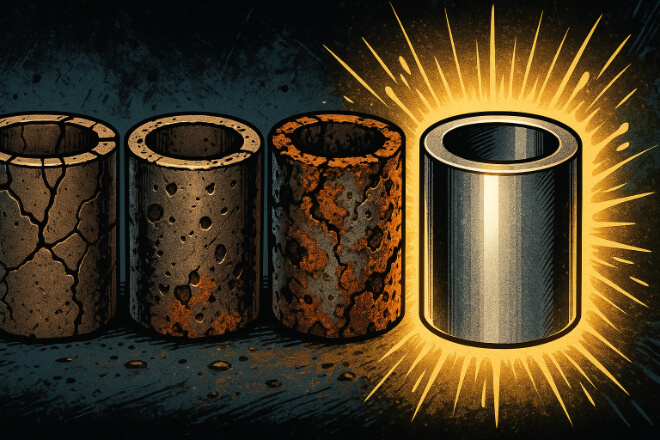

Failure Modes and How to Prevent Them

Even tungsten carbide can fail if conditions are extreme or incorrect grade is used.

1). Typical failure types

Binder leaching in strongly acidic media

Cracking due to misalignment

Abrasive wear from solid particles

Corrosion when cobalt binder reacts with chemicals

2). Prevention guidelines

Choose WC-Ni for corrosive media

Maintain shaft alignment

Ensure proper clearance

Control vibration

Use clean flushing or lubrication

Inspect early for micro-pits

Choosing the Right Supplier for Chemical Applications

Chemical plants need reliable suppliers who understand corrosive environments.

Supplier checklist

Experience with chemical pumps

Ability to supply WC-Ni and WC-Co grades

HIP sintering capability for high density

Full traceability and documentation

Ability to make custom designs

Fast lead time

Selecting the right supplier ensures long service life, stable performance, and reduced plant maintenance.

結論

Chemical plants specify tungsten carbide bushings because they offer exceptional corrosion resistance, outstanding wear performance, and long service life in aggressive chemical environments.

By choosing the right grade, maintaining correct alignment, and working with a reliable supplier, plant operators can greatly reduce downtime and operating cost.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。