Agricultural equipment works in some of the harshest environments. Soil, sand, stones, moisture, and repeated impact all place heavy stress on wear parts. Downtime during planting or harvesting seasons can be very costly.

Because of this, many equipment manufacturers and farm operators choose タングステンカーバイドチップ to improve durability, reduce maintenance, and keep machines running longer in the field.

Harsh Working Conditions in Agricultural Operations

Agricultural tools operate directly in contact with the ground. Unlike controlled factory environments, field conditions change constantly.

Common challenges include:

Abrasive soil with sand and grit

Hidden rocks and hard debris

Moisture, mud, and chemicals from fertilizers

Long operating hours during peak seasons

Standard steel tips wear fast under these conditions, leading to frequent replacements and lost productivity.

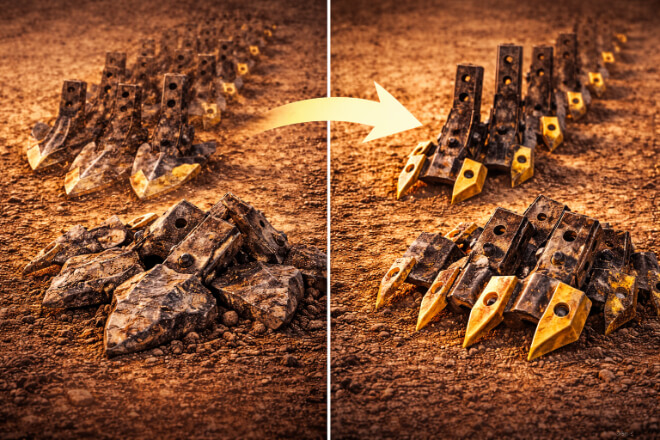

Why Tungsten Carbide Tips Perform Better Than Steel

Tungsten carbide tips are much harder than regular steel. This hardness allows them to resist wear even when cutting through soil mixed with sand and small stones.

Key performance advantages:

Slower edge wear

Better resistance to scratching and erosion

Stable shape over long use

For agricultural equipment, this means tools stay effective longer without constant adjustment.

Improved Wear Life in Soil and Sand

Soil abrasion is the main cause of failure for agricultural wear parts. Every pass through the ground removes material from the tool edge.

Reduce material loss during soil contact

Maintain sharp working edges longer

Perform well in both dry and wet soil

This extended wear life directly lowers replacement frequency.

Better Impact Resistance Against Rocks and Debris

Fields often contain stones that are not visible from the surface. When tools strike these objects, impact damage can occur.

Properly selected tungsten carbide grades offer:

Strong resistance to chipping

Better load distribution at the tip

Reduced cracking compared to brittle materials

This improves tool reliability during unpredictable field conditions.

Maintaining Cutting Efficiency Over Long Operating Hours

Agricultural work often involves long, continuous operation. As tool edges wear, cutting efficiency drops and fuel consumption increases.

Tungsten carbide tips help by:

Keeping a consistent cutting profile

Reducing drag during soil penetration

Supporting stable machine performance

This allows equipment to work efficiently throughout long shifts.

Reduced Downtime During Critical Farming Seasons

Downtime during planting or harvesting can delay operations and reduce yield. Frequent tool changes increase labor costs and interrupt workflow.

Using tungsten carbide tips helps:

Extend service intervals

Reduce emergency replacements

Improve operational planning

For decision-makers, this means better equipment availability when timing matters most.

Common Agricultural Equipment Using Tungsten Carbide Tips

Tungsten carbide tips are widely used in:

Plow points and cultivator tools

Tillage and soil preparation equipment

Harvesting and cutting components

Wear parts exposed to soil abrasion

Their use continues to grow as farms move toward higher efficiency and lower maintenance costs.

Cost Efficiency Over the Equipment Lifetime

Although tungsten carbide tips have a higher initial cost than steel, the total cost over time is often lower.

Long-term benefits include:

交換品の減少

Less machine downtime

Lower labor and service costs

When evaluated over a full season or equipment life cycle, carbide-tipped tools often deliver better value.

結論

Tungsten carbide tips are preferred in agricultural equipment because they handle abrasion, impact, and long operating hours far better than steel. They help reduce downtime, maintain cutting efficiency, and lower overall maintenance costs.

For agricultural equipment manufacturers and farm operators, tungsten carbide tips support reliable performance and better return on investment in demanding field conditions.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。