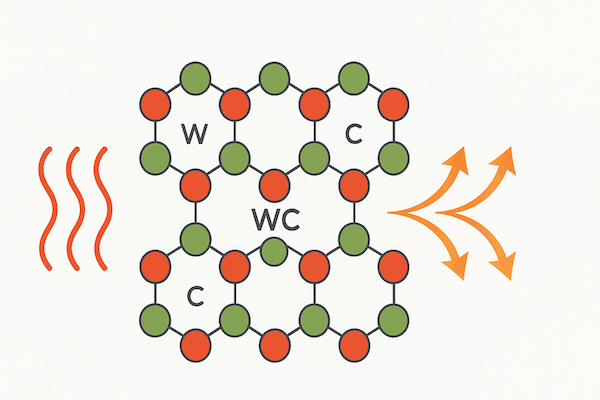

텅스텐 카바이드 산업의 열 안정성: 설명적 개요

서론 첨단 소재 분야에서 텅스텐 카바이드(WC)는 뛰어난 경도, 내마모성, 높은 녹는점으로 두드러집니다. 이러한 특성으로 인해 광업, 항공우주, 제조, 자동차 분야를 포함한 다양한 산업에서 없어서는 안 될 재료입니다. 수많은 유리한 특성 중 열 안정성은 성능에 상당한 영향을 미치는 핵심 특성입니다.

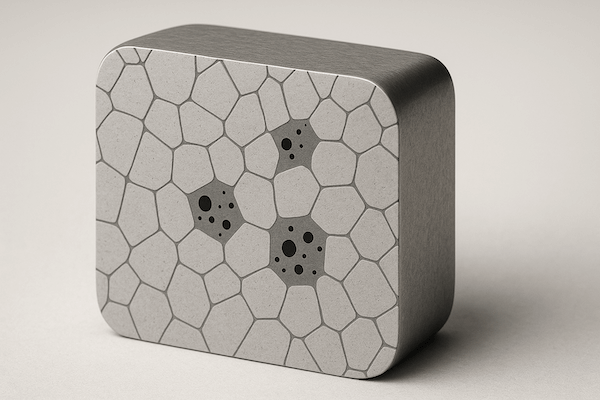

텅스텐 카바이드 산업의 다공성: 설명적 개요

서론 다공성은 재료 과학, 특히 산업용 공구에 사용되는 텅스텐 카바이드(WC)와 같은 고성능 소재에서 중요한 개념입니다. 흔히 간과되지만, 다공성은 초경 공구의 기계적 강도, 내마모성, 그리고 전반적인 신뢰성을 결정하는 데 중요한 역할을 합니다. 본 논문에서는 다공성이 무엇이고, 어떻게 형성되는지, 그리고 […]

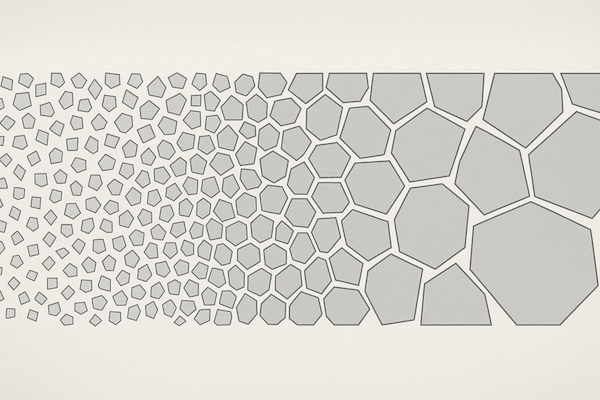

텅스텐 카바이드 공구의 입자 크기 이해

첨단 소재 및 공구 분야에서 자주 등장하는 용어 중 하나는 "입자 크기"입니다. 야금학자만 관심을 갖는 세부 사항처럼 들릴 수 있지만, 입자 크기는 광업, 기계 가공, 석유 및 가스, 정밀 제조 산업에서 사용되는 텅스텐 카바이드 공구의 성능, 강도 및 내구성에 중요한 역할을 합니다. 그렇다면 […]

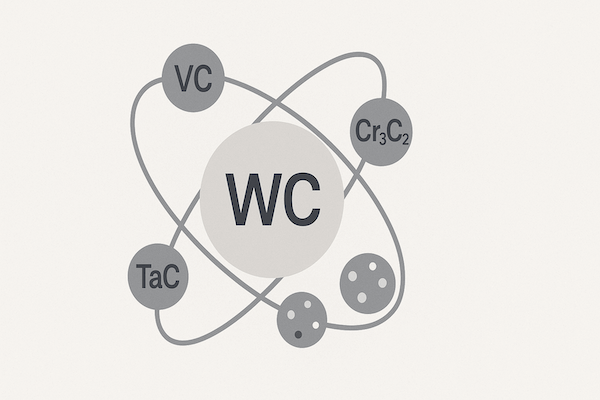

텅스텐 카바이드 공구의 합금 원소 이해

텅스텐 카바이드 공구는 탁월한 경도, 내마모성, 그리고 극한의 작업 조건을 견뎌내는 능력으로 유명합니다. 하지만 이러한 놀라운 성능의 이면에는 WC와 코발트뿐만 아니라 엄선된 합금 원소의 영향도 있습니다. 이러한 미량 첨가물은 양은 적지만 공구의 거동에 큰 영향을 미칩니다. […]