텅스텐 카바이드 절삭 공구의 수명 연장을 위한 유지 관리 팁

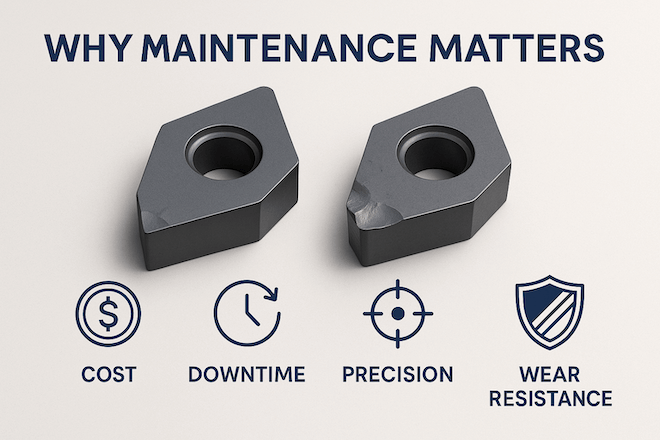

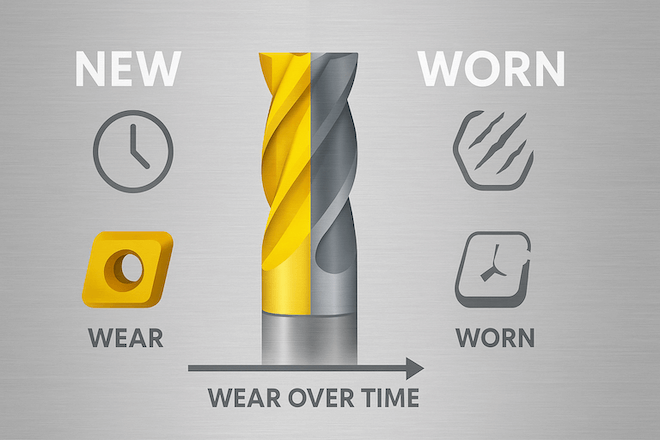

텅스텐 카바이드 절삭 공구는 뛰어난 경도, 강도, 그리고 내마모성으로 잘 알려져 있습니다. 하지만 아무리 견고한 공구라도 수명이 길고 성능이 향상되려면 적절한 관리가 필요합니다. 적절한 유지 관리를 통해 가동 중단 시간을 줄이고 비용을 절감하며 생산 품질을 향상시킬 수 있습니다. 이 글에서는 […]를 연장하는 데 도움이 되는 간단하고 효과적인 유지 관리 팁을 소개합니다.

텅스텐 카바이드 절삭 공구가 뛰어난 내마모성을 갖는 이유

현대 제조업에서 올바른 절삭 공구를 선택하는 것은 매우 중요합니다. 공구는 견고하고 정밀하며 오래 사용할 수 있어야 합니다. 텅스텐 카바이드 절삭 공구는 뛰어난 내마모성 덕분에 업계에서 신뢰를 얻고 있습니다. 이 블로그에서는 텅스텐 카바이드의 견고한 특성과 다른 소재보다 오래 사용할 수 있는 이유를 설명합니다. […]

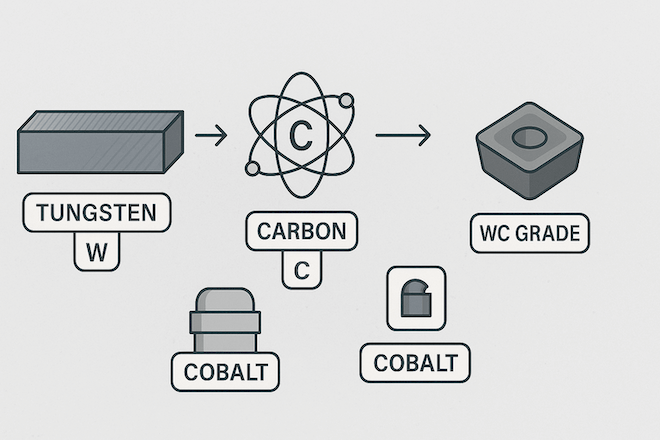

절삭 공구 응용 분야를 위한 텅스텐 카바이드 등급 이해

소개: 텅스텐 카바이드 공구에서 재종이 중요한 이유 텅스텐 카바이드 절삭 공구를 사용할 때 재종을 이해하는 것이 중요합니다. 재종은 공구의 경도, 인성, 그리고 최적의 용도를 정의합니다. 이 가이드는 텅스텐 카바이드 재종이 무엇이고, 왜 중요한지, 그리고 적합한 재종을 선택하는 방법을 이해하는 데 도움을 드립니다. 텅스텐 카바이드 재종이란 무엇일까요? […]