가동 중단 시간 최소화: 텅스텐 카바이드 볼의 장기적 가치

광업, 석유 및 가스, 항공우주, 중장비와 같은 산업에서는 가동 중단 시간 1시간마다 비용이 발생합니다. 작은 부품 하나가 원활한 운영과 예상치 못한 가동 중단의 차이를 만들어내는 경우가 많습니다. 텅스텐 카바이드 볼은 이러한 부품 중 하나이며, 장기적인 가치는 가동 중단 시간 단축, 장비 수명 연장, 그리고 총 운영 비용 절감에 있습니다. […]

텅스텐 카바이드 볼 사용의 수명 및 비용 이점

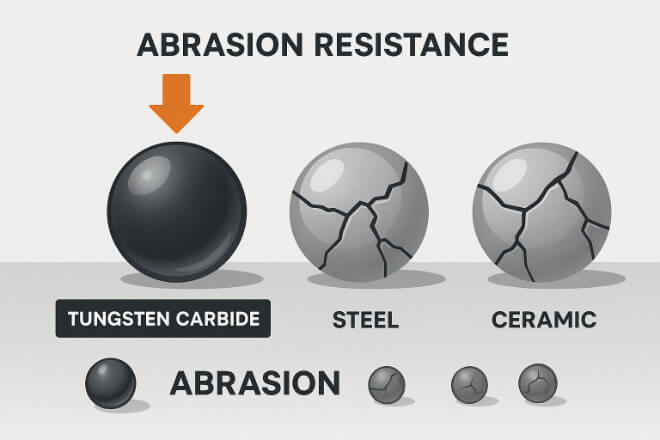

광업, 석유 및 가스, 항공우주, 정밀 제조와 같은 산업의 의사 결정권자들은 초기 공구 비용과 장기적인 성능 간의 균형을 맞추는 것이 얼마나 어려운지 잘 알고 있습니다. 텅스텐 카바이드 볼은 긴 수명과 뛰어난 비용 효율성을 모두 갖추고 있어 신뢰할 수 있는 선택이 되었습니다. 초기 구매 비용은 강철이나 세라믹 볼보다 높을 수 있지만, 전체적인 가치는 […]

다른 고마모 재료 대신 텅스텐 카바이드를 선택하는 경우

중공업 분야에서 의사 결정권자들은 종종 한 가지 중요한 과제에 직면합니다. 바로 지속적인 마모, 열 또는 압력을 견뎌야 하는 부품에 적합한 소재를 선택하는 것입니다. 경화강, 세라믹, 스텔라이트, 복합재와 같은 소재가 널리 사용되지만, 텅스텐 카바이드가 특히 주목받는 경우가 많습니다. 다른 고마모 소재보다 텅스텐 카바이드를 언제 선택해야 하는지 아는 것은 비용 절감과 성능 향상에 도움이 될 수 있습니다. […]

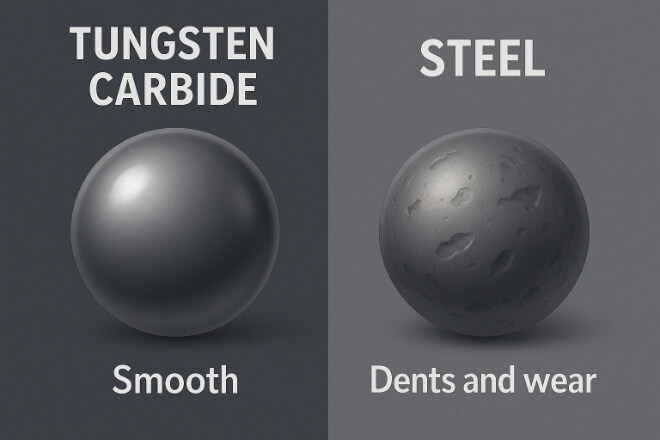

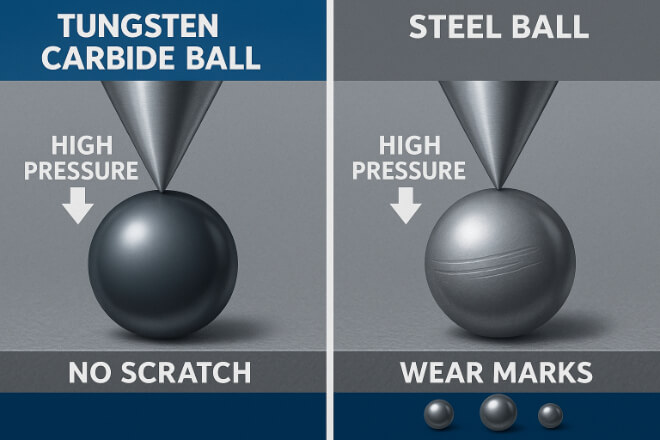

텅스텐 카바이드 볼과 스틸 볼: 성능 비교

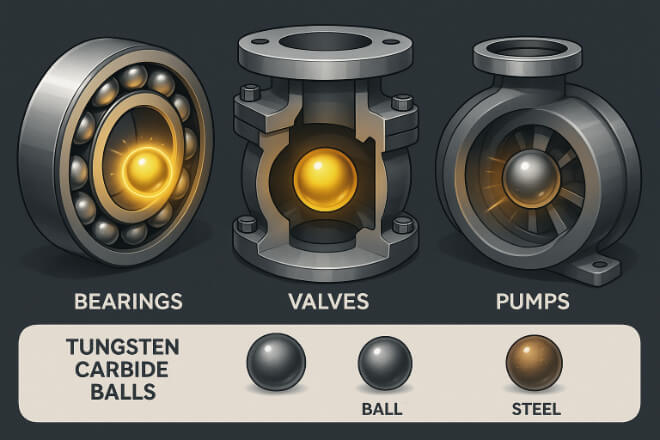

베어링, 밸브부터 밀링 미디어, 항공우주 부품에 이르기까지 다양한 산업 분야에서 하중, 마찰, 마모를 처리하기 위해 다양한 재질의 볼이 사용됩니다. 그중에서도 텅스텐 카바이드 볼과 스틸 볼이 가장 널리 사용됩니다. 언뜻 보기에는 비슷해 보이지만 성능은 매우 다릅니다. 두 볼 중 어떤 것을 선택해야 할지 […]

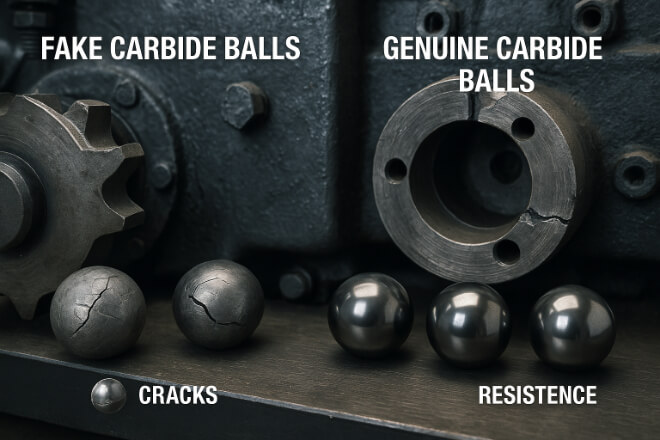

위조 카바이드 볼 식별 방법: 무게 및 밀도 계산

베어링부터 밸브, 밀링 머신에 이르기까지 글로벌 산업에서 텅스텐 카바이드 볼은 중요한 역할을 합니다. 높은 경도, 내마모성, 그리고 밀도 덕분에 강철이나 세라믹 볼보다 선호되는 경우가 많습니다. 그러나 카바이드 볼의 인기는 위조 제품이라는 문제도 야기했습니다. 가짜 카바이드 볼은 […]