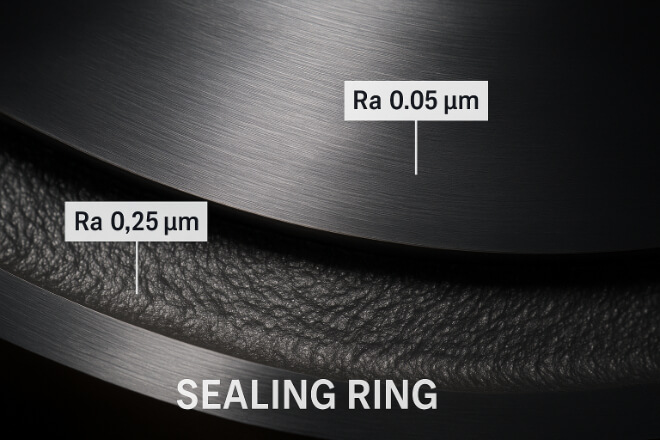

씰링 링의 표면 지형: Ra 0.04–0.05 μm의 실제 의미

기계적 씰에서 씰링 링의 표면 형상은 누출 제어, 윤활 유지 및 내마모성에 직접적인 영향을 미칩니다. 고성능 어플리케이션에서는 0.04~0.05μm 사이의 Ra 값이 종종 지정되지만, 많은 의사 결정권자들은 이 값이 실제로 무엇을 나타내는지, 그리고 왜 중요한지 궁금해할 수 있습니다. 이 글에서는 Ra 0.04~0.05μm의 값과 그 영향을 간략하게 설명합니다. […]

카바이드 씰 링에서 거울 수준 마감 달성: 공정 창 및 함정

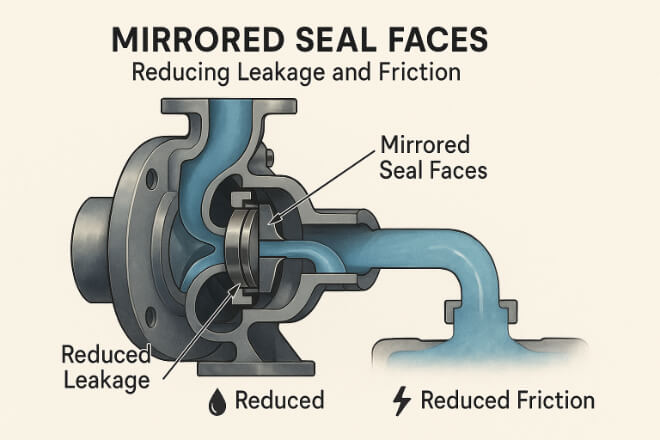

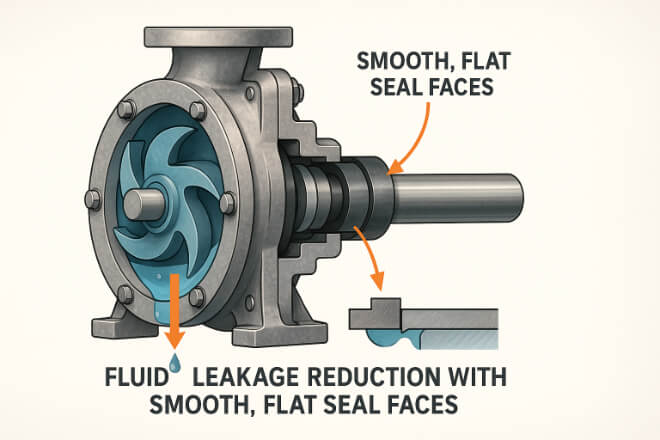

카바이드 씰 링은 석유 및 가스, 화학 처리, 발전, 해양 시스템 등의 산업에서 펌프, 압축기, 밸브에 필수적인 부품입니다. 이러한 링에 거울과 같은 수준의 마감 처리를 하면 누출 제어, 낮은 마찰, 그리고 긴 장비 수명을 보장합니다. 그러나 완벽한 거울 마감을 달성하는 것은 쉽지 않습니다. 엄격한 공정 조건이 요구되기 때문입니다. […]

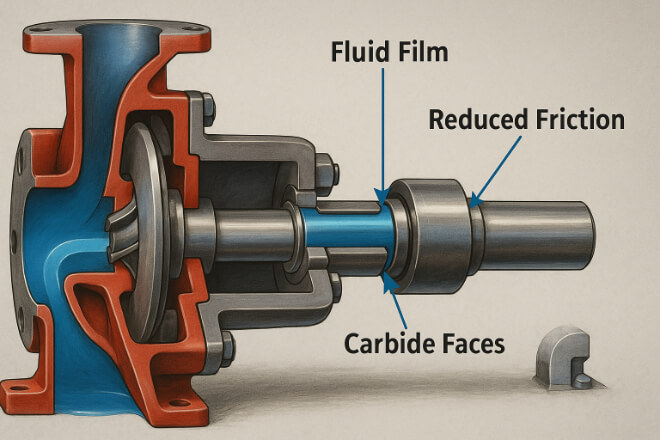

초미세 마감과 미세 포켓 마감: 초경 표면의 윤활 유지

기계적 씰에서 초경 표면의 표면 마감은 누설 제어뿐만 아니라 윤활 유지에도 영향을 미칩니다. 널리 사용되는 두 가지 마감 방식, 즉 초미세 마감과 미세 포켓 마감은 작동 조건에 따라 각기 다른 이점을 제공합니다. 석유 및 가스, 화학 처리, 해양 시스템, 발전 산업 분야의 의사 결정권자에게 이러한 마감을 이해하는 것은 씰 성능을 개선하는 데 도움이 됩니다. […]

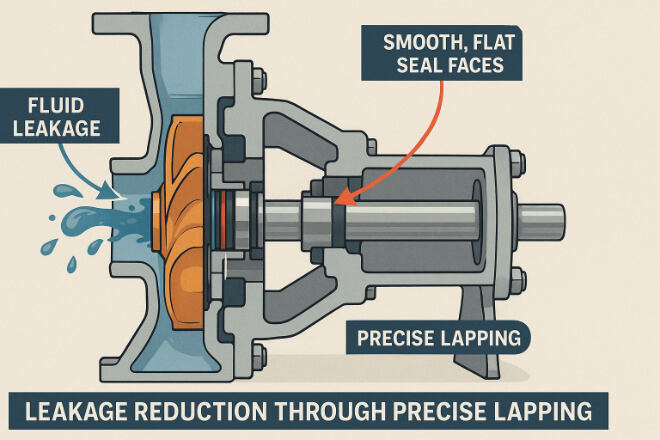

카바이드 페이스 래핑을 위한 컨디셔닝 링, 플레이트 선택 및 슬러리 제어

기계적 씰 제조 및 유지보수에서 초경 페이스 래핑은 중요한 마무리 공정입니다. 적절한 래핑은 표면 평탄도, 낮은 거칠기(Ra), 그리고 견고한 밀봉 성능을 보장합니다. 컨디셔닝 링, 래핑 플레이트 선택, 그리고 슬러리 제어라는 세 가지 핵심 요소가 마무리의 품질과 반복성을 결정합니다. 본 가이드는 이러한 요소들이 초경 페이스 래핑에 미치는 영향을 설명하고 […]

초경 씰 표면의 목표 Ra 및 평탄도: 래핑 및 연마 모범 사례

카바이드 씰 면은 석유 및 가스, 발전, 화학 처리, 수처리 등의 산업에서 펌프, 압축기, 밸브에 매우 중요합니다. 이러한 씰 면의 표면 거칠기(Ra)와 평탄도는 누출 제어, 내마모성, 장비 신뢰성에 직접적인 영향을 미칩니다. 래핑과 연마는 최종 Ra를 결정하는 두 가지 필수 마무리 공정입니다. […]