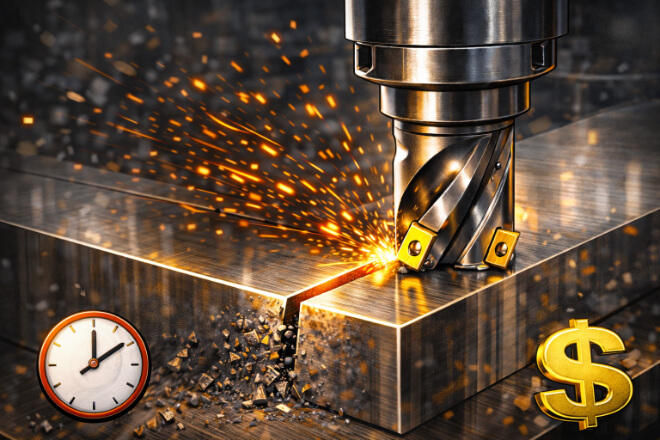

Thermal Stability of Tungsten Carbide Tips in High-Speed Machining

In high-speed machining operations, such as milling, drilling, and turning, cutting tools are subjected to extreme conditions, including high temperatures generated by friction. Maintaining tool performance under these conditions is crucial for both efficiency and the quality of the finished product. Tungsten carbide tips are widely used in high-speed machining because of their exceptional hardness, […]

Comparing Tungsten Carbide Tip Grades for Extreme Wear Applications

Tungsten carbide is widely known for its strength and durability, making it a top choice for cutting tools used in high-wear applications. However, not all tungsten carbide tips are the same. Different grades of tungsten carbide offer various benefits depending on the specific requirements of the job. For industries that deal with extreme wear, such […]

Hardness vs Toughness: Designing Tungsten Carbide Tips for Long Tool Life

When designing cutting tools, especially those used for demanding tasks like machining, mining, or construction, two key properties are often discussed: hardness and toughness. Both are critical, but they serve different purposes in tool performance. For tungsten carbide tips, a careful balance between these two properties is essential to achieve the best possible tool life. […]

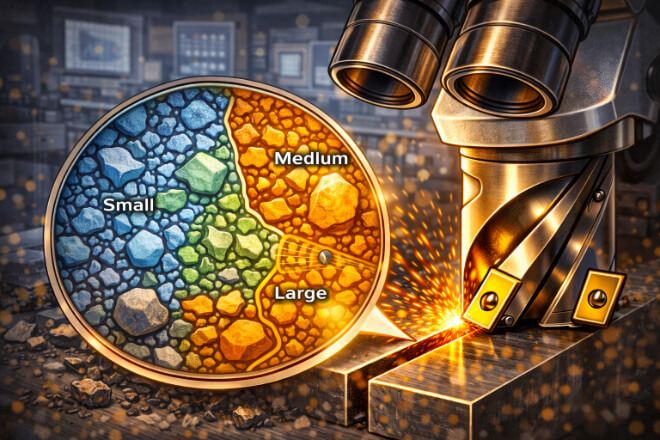

How Grain Size Control Affects Tungsten Carbide Tip Durability and Wear Resistance

When it comes to tungsten carbide tips used in cutting tools, their durability and wear resistance are essential to maintaining high-performance standards. These properties determine how long the tool lasts, how efficiently it cuts, and how much maintenance it requires. One of the most significant factors influencing these properties is grain size. Grain size control […]

Why Tungsten Carbide Tips Are Superior in High-Heat and High-Friction Cutting Jobs

Cutting through tough materials like metal, stone, or high-density plastics often leads to extremely high temperatures and friction. These factors can cause rapid wear and tear on cutting tools, resulting in reduced performance and frequent tool changes. Tungsten carbide tips are widely regarded as the ideal solution for high-heat and high-friction cutting jobs due to […]