Pumps are critical components in industries like 석유와 가스, power generation, chemical processing, and marine operations.

A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable.

텅스텐 카바이드 씰 링 are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers.

Why Leak-Free Pump Operation Matters

Prevents fluid loss → Protects resources and reduces waste.

Maintains efficiency → Pumps perform better without pressure loss.

Reduces maintenance costs → Fewer failures mean fewer repairs.

Protects the environment → Prevents spills of hazardous materials.

Ensures safety → Avoids dangerous leaks near operators or equipment.

텅스텐 카바이드 씰 링의 특성

텅스텐 카바이드는 텅스텐과 탄소가 코발트 또는 니켈과 결합된 화합물입니다. 다음과 같은 특성을 지닙니다.

극심한 경도 → 마찰과 입자로 인한 마모를 방지합니다.

높은 압축 강도 → Handles heavy loads without cracking.

부식 저항성 → Works well with chemicals, seawater, and oils.

열 안정성 → Maintains sealing performance under high heat.

치수 안정성 → Ensures precise sealing over long periods.

These properties help pumps stay leak-free under tough conditions.

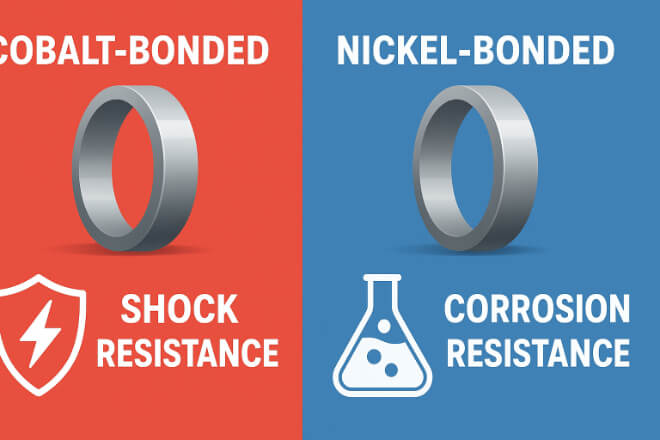

코발트 결합 텅스텐 카바이드 vs 니켈 결합 텅스텐 카바이드

1) 코발트 결합 텅스텐 카바이드

Best for vibration-heavy or high-shock pumps.

Common in oilfield and mining operations.

2) 니켈 결합 텅스텐 카바이드

우수한 내식성.

Ideal for chemical plants, marine pumps, and wastewater systems.

Choosing the right binder ensures long service life and reliable sealing.

다른 씰 재료에 비해 장점

| 특징 | 텅스텐 카바이드 | 세라믹 | 강철 |

|---|---|---|---|

| 내마모성 | Excellent for abrasives | 보통의 | 가난한 |

| 부식 저항성 | High (nickel grades) | 매우 좋은 | 낮은 |

| 강인함 | 높고 충격에 강함 | 낮음, 취성 | 보통의 |

| Thermal Performance | Excellent at high heat | 좋은 | 보통의 |

| Service Life | 오래 지속되는 | 보통의 | 짧은 |

Applications in Pump Systems

텅스텐 카바이드 씰 링은 다음에서 사용됩니다.

Chemical pumps → Handle aggressive fluids safely.

해양 펌프 → Resist seawater corrosion.

Oil and gas pumps → Prevent leaks under pressure.

Wastewater pumps → Manage abrasive and corrosive fluids.

발전소 냉각 펌프 → Maintain leak-free operation for critical systems.

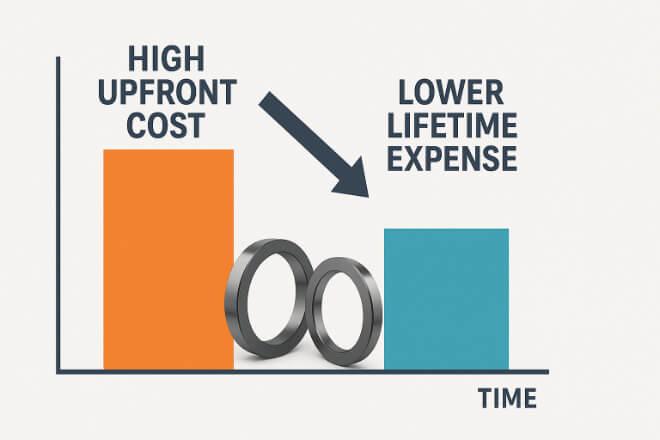

비용 대 장기적 가치

While tungsten carbide rings cost more upfront:

교체 횟수 감소 → 예비 부품 비용이 낮습니다.

가동 중지 시간 감소 → Increases production efficiency.

장비 수명 연장 → Protects pump components.

더 나은 투자 수익률 → Long-term savings outweigh initial price.

Environmental and Safety Benefits

Leak prevention → Avoids contamination and environmental damage.

Recyclable material → Supports sustainable practices.

Energy efficiency → Preventing leaks reduces wasted energy.

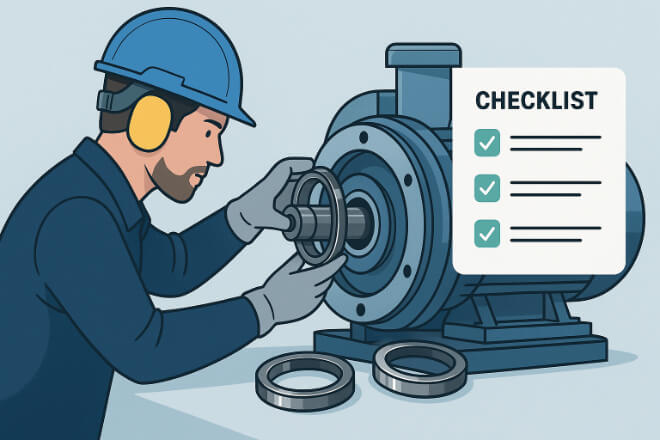

Best Practices for Leak-Free Performance

올바른 바인더를 선택하세요 → Match to chemical and mechanical conditions.

Ensure proper installation → 긁힘이나 정렬 불량을 방지하세요.

적절한 윤활을 사용하세요 → Reduces friction and heat.

정기적으로 검사하세요 → Catch wear early before leaks start.

Partner with reliable suppliers → 재료 품질과 올바른 사양을 확인하세요.

의사결정자를 위한 주요 정보

텅스텐 카바이드 씰 링 ensure leak-free pump operation under tough conditions.

Choosing the correct grade (nickel or cobalt) is critical for performance.

Their durability, recyclability, and efficiency lower costs and environmental risks.

Investing in tungsten carbide protects pumps and improves ROI.

결론

For pumps in chemical plants, power stations, marine systems, and oilfields, tungsten carbide seal rings are a proven choice for preventing leaks.

Their hardness, corrosion resistance, and strength deliver long-term performance, reduced downtime, and environmental protection.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, sustainability, and cost efficiency.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.