Cryogenic and extreme cold environments—such as liquefied natural gas (LNG) plants, 항공우주 testing facilities, scientific labs, and deep-sea systems—require sealing solutions that can perform reliably at very low temperatures.

In these environments, materials become brittle, fluids behave differently, and any failure can cause costly downtime or safety hazards.

텅스텐 카바이드 씰 링 are a trusted choice for pumps, compressors, and turbines operating in these harsh conditions.

This article explains their properties, advantages, applications, and best practices for decision-makers.

Challenges of Cryogenic and Extreme Cold Conditions

Operating at temperatures as low as -196 °C (-320 °F) creates challenges:

Material brittleness → Metals and plastics can crack or deform.

Thermal contraction → Components shrink, causing misalignment.

Lubrication issues → Fluids thicken or freeze, increasing friction.

Seal failure risks → Even small leaks can cause dangerous situations.

가동 중지 비용 → Repairs at cryogenic facilities are expensive.

텅스텐 카바이드 씰 링의 특성

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for extreme cold:

코발트 결합 텅스텐 카바이드 vs 니켈 결합 텅스텐 카바이드

1) 코발트 결합 텅스텐 카바이드

Greater impact resistance.

Suitable for pumps and compressors exposed to vibration.

2) 니켈 결합 텅스텐 카바이드

우수한 내식성.

Best for cryogenic systems handling oxygen, hydrogen, or chemical-rich fluids.

다른 씰 재료에 비해 장점

| 특징 | 텅스텐 카바이드 | 세라믹 | 강철 |

|---|---|---|---|

| Low-Temperature Toughness | 훌륭한 | 낮음, 취성 | 보통의 |

| 내마모성 | 훌륭한 | 보통의 | 가난한 |

| 부식 저항성 | High (nickel grades) | Very Good | 낮은 |

| Thermal Contraction | 낮은 | 보통의 | 높은 |

| Service Life | 오래 지속되는 | 보통의 | 짧은 |

Applications in Cryogenic and Cold Environments

텅스텐 카바이드 씰 링 are widely used in:

LNG pumps and compressors → Ensure leak-free transfer of liquefied gases.

Aerospace cryogenic testing systems → Handle extreme cold during rocket or satellite testing.

Scientific laboratories → Maintain seal integrity in liquid nitrogen systems.

Marine deep-sea equipment → Resist high pressure and freezing seawater.

Hydrogen fuel systems → Provide safe sealing for clean energy applications.

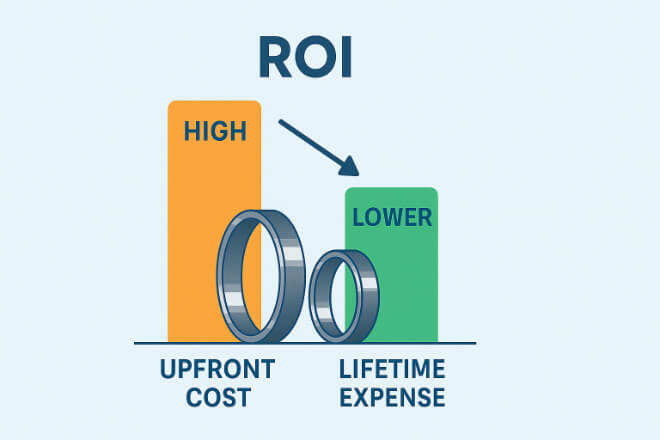

비용 대 장기적 가치

While tungsten carbide seal rings have a higher upfront price, they:

더 오래 지속되어 가동 중지 시간을 줄이세요.

교체 횟수가 줄어들어 유지관리 비용이 낮아집니다.

Protect critical equipment from leaks and damage.

Deliver better ROI in high-risk, cold environments.

Environmental and Safety Benefits

Leak prevention → Reduces risk of environmental contamination.

Recyclable material → Supports sustainability goals.

Improved efficiency → Leak-free systems consume less energy.

텅스텐 카바이드 씰 링 사용 모범 사례

Match binder to environment → Nickel for corrosive cryogenic fluids, cobalt for high vibration.

적절한 설치 기술을 사용하세요 → 긁힘이나 정렬 불량을 방지하세요.

정기적으로 검사하세요 → Spot wear or contraction damage early.

경험이 풍부한 공급업체와 협력하세요 → Ensure correct specifications for cryogenic conditions.

Plan maintenance schedules → Avoid unplanned shutdowns in critical systems.

의사결정자를 위한 주요 정보

Tungsten carbide seal rings are the best choice for cryogenic and extreme cold applications.

Their low thermal expansion, 내식성, 그리고 강인함 prevent leaks and damage.

Correct binder selection (nickel or cobalt) maximizes reliability.

Investing in tungsten carbide reduces downtime, cost, and environmental risks.

결론

In cryogenic and extreme cold systems, seal reliability is critical. Tungsten carbide seal rings provide unmatched performance, ensuring pumps, compressors, and turbines remain leak-free even under severe conditions.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, efficiency, and sustainability.

회사에 대한 자세한 내용을 알고 싶으시면 언제든지 문의해 주세요. 문의하세요.